17

10

10

10

10----4 Overlap of the upper and lower knives

4 Overlap of the upper and lower knives

4 Overlap of the upper and lower knives

4 Overlap of the upper and lower knives

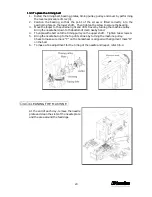

When upper knife J is at the bottom of its stroke,

adjust the overlap of the upper and lower knives as

shown in the illustration. To increase the overlap,

loosen screw K on the upper knife lever and move

the upper knife in the direction of arrow X.

To decrease the overlap, move the upper knife in the

direction of arrow Y. When the correct overlap is

achieved, tighten screw K.

10

10

10

10----5 Adjusting the stroke of the upper knife

5 Adjusting the stroke of the upper knife

5 Adjusting the stroke of the upper knife

5 Adjusting the stroke of the upper knife

Set the stroke of the upper knife at approximately

8mm. To change the stroke, loosen nut L on the

upper knife adjusting lever pin.

■

To decrease the stroke, move lever pin M in the

direction of Y.

■

To increase the stroke, move lever pin M in the

direction of X.

After the adjustment, tighten nut L securely.

Adjustment of the stroke will change the overlap of

the upper and lower knives.

Be sure to achieve the correct overlap by referring to

10-4.

10

10

10

10----6 Resharpening the knives

6 Resharpening the knives

6 Resharpening the knives

6 Resharpening the knives

Since the upper knife is made of a superalloy, there

is no need to resharpen it about one year.

If cutting does not occur, resharpen the lower knife.