7

< Note >

After the above adjustment, check to make sure each

needle drops into the center of each needle hole.

<Note>

Make sure the setting distance is not changed when the

looper holder is moved front or back.

5555----4 Needle height

4 Needle height

4 Needle height

4 Needle height

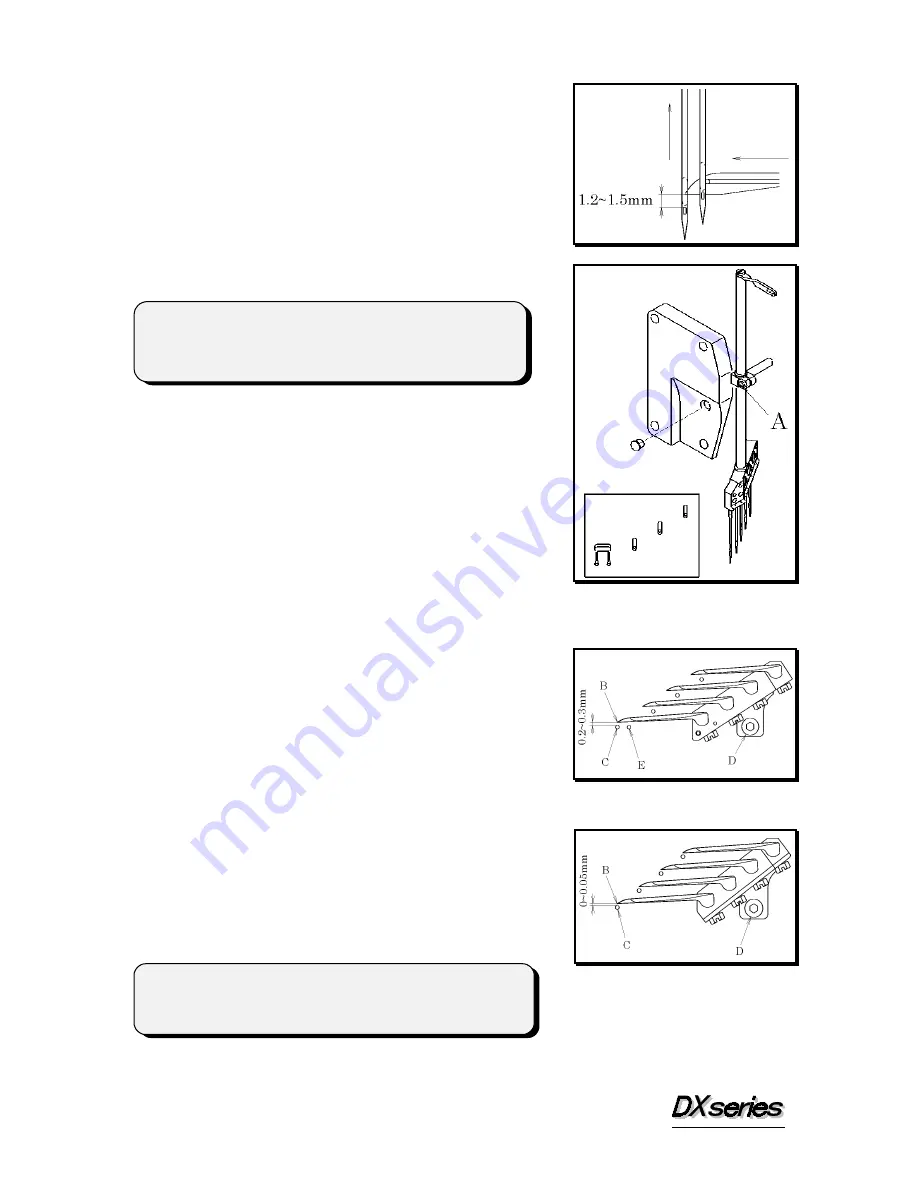

The point of the looper should be 1.2~1.5mm above the

top of the left needle's eye on the back side of the

needle when the point of the looper has reached the

center of the left needle with the machine pulley

turning in the operating direction (see 5-2).

■

To adjust the height of the needle,

1. Set the needle bar at the top of its stroke.

2. Remove the plug on the head cover.

3. Loosen screw A.

4. Move the needle bar up or down.

5555----5 Needle/looper front

5 Needle/looper front

5 Needle/looper front

5 Needle/looper front----to

to

to

to----back relationship

back relationship

back relationship

back relationship

■

2-3U

When point B of the looper reaches left needle C, there

should be a clearance of 0.2~0.3mm between point B of

the looper and left needle C. When point B of the

looper reaches right needle E, they should slightly

touch with each other. Adjustment is made by

loosening screw D on the looper holder. After the

above adjustments are made, the clearance between

the point of the looper and right needle E should be

0~0.05mm with right needle E deflected by the needle guard (rear).

■

004U

When point B of the looper reaches needle C, point B of

the looper should slightly touch needle C.

Adjustment is made by loosening screw D on the looper

holder. After the above adjustments are made, the

clearance between point B of the looper and needle C

should be 0~0.05mm with needle C deflected by the

needle guard (rear).