3

NC

series

【

2

】

MACHINE SPEED

2-1 Machine speed & operating direction

Refer to the table below for maximum and standard speeds of

the Series. To extend machine life, run the machine

approximately 15~20% below the maximum speed for the first

200 hours of operation (approx. 1 month). Then run the

machine at the standard speed.

The machine pulley turns clockwise as the handwheel does as

seen from the machine pulley

2-2 Motor & belt

Motor : 3-phase, 2-pole, 400W clutch motor

Belt

: M type V belt

Select the proper motor pulley according to the machine speed

(refer to the motor pulley outer diameter on the table below).

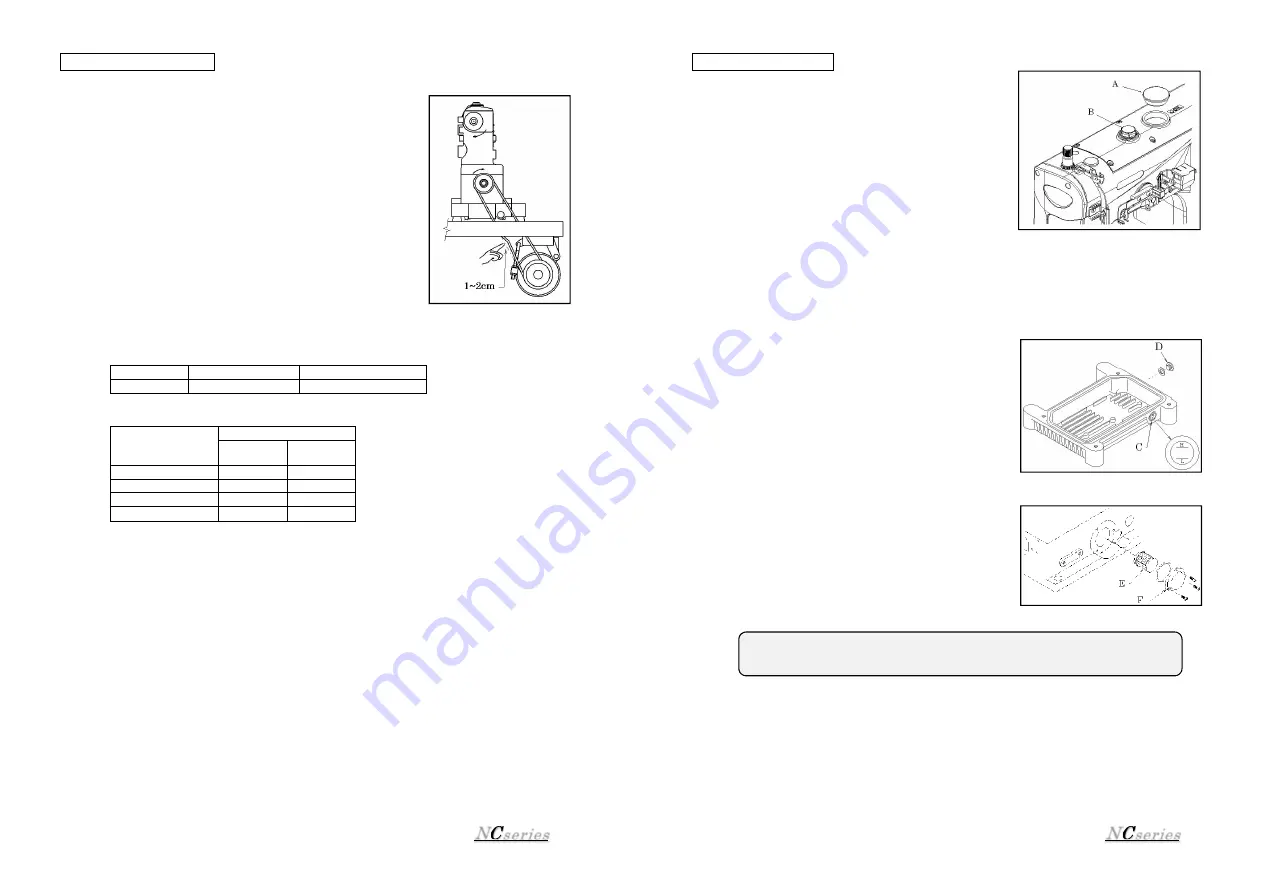

Adjust where to position the motor by pressing the finger onto

the middle of the belt so that 1~2cm deflection can be achieved

(see the illustration on the right)

< Machine speed >

TYPE

MAXIMUM SPEED

STANDARD SPEED

NC1103

4,500rpm

4,000rpm

< Motor pulley selection table >

Motor pulley outer

diameter (mm)

Machine speed (rpm)

50Hz

60Hz

80

3,500

4,200

90

4,000

4,800

100

4,400

110

4,900

4

NC

series

< Note >

When the oil filter cap is removed, the oil collected on the element drips. Be careful.

【

3

】

LUBRICATION

3-1 Oil

Use Kansai Special’s genuine oil.

(Part No. 28-618 :700cc)

3-2 Oiling

■

To fill the machine with oil

Remove rubber plug A from the oil hole.

Fill the machine with oil until the oil level is at the

top line (see H in the illustration) on oil gauge C.

After the first lubrication, add oil so that the oil level

will be between H and L.

■

To check for proper oil flow

After filling the machine with oil, run the machine to check the oil is splashing to oil flow

sight window B.

3-3 Replacing the oil and the oil element

To extend machine life, be sure to replace the oil after

the first 250 hours of operation.

To replace the oil, follow the procedures below.

1.

Remove the V belt from the motor pulley and then

remove the machine from the table.

2.

Remove screw D and then drain the oil.

Be careful not to stain V belt with the oil.

3.

After draining the oil, be sure to tighten screw D.

4.

Fill the machine with oil by referring to 3-2 shown

above.

If element E is contaminated, proper oiling may not be

performed. Clean the filter element every six

months. If just a little or no oil flows out from the

nozzle with the proper amount of oil in the machine,

check the element. To do so, remove oil filter cap F.

Replace the element if necessary.

Summary of Contents for NC Series

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 51: ...NC Series Instruction Manual NC1103 4 G series ...

Page 63: ...NC J SJ Series Instruction Manual NC1001GSJ NC1001GSJF NC1001GJ ...