16

10

10

10

10----7 Position of the looper thread take

7 Position of the looper thread take

7 Position of the looper thread take

7 Position of the looper thread take----up

up

up

up

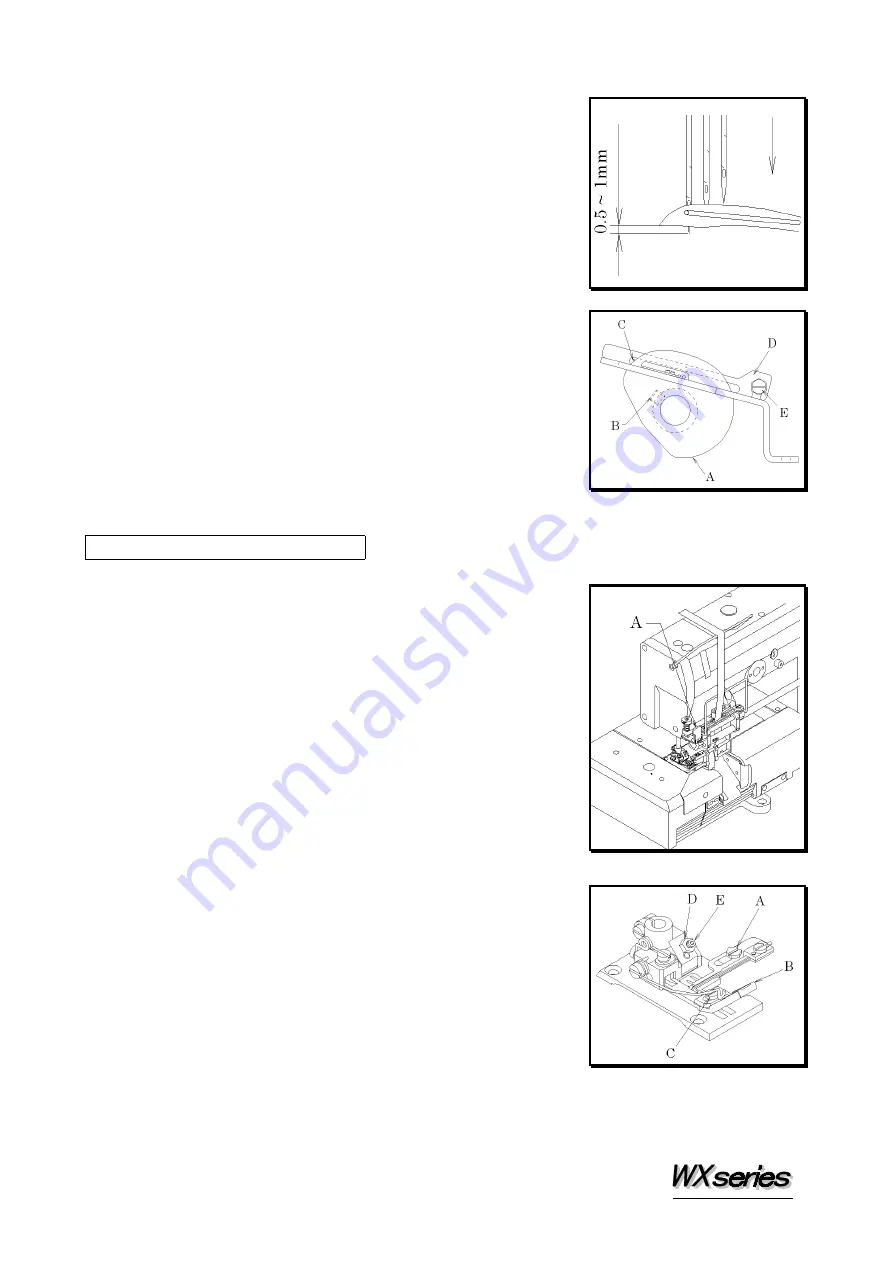

Thread guide D should be at the center of the groove of

looper thread take-up A. When the point of the left

needle has reached 0.5~1mm above the bottom surface of

the looper blade while the looper is moving from the

extreme left end of its travel, the looper thread should be

removed from position C on the looper thread take-up.

To make this adjustment, loosen screw B and adjust the

looper thread take-up. To adjust the height of thread

guide D, loosen screw E and then align the bottom of the

slot of thread guide D with the top surface of the bracket.

【

11

】

EMK ELASTIC FEEDER

11

11

11

11----1 To insert the lace/elastic

1 To insert the lace/elastic

1 To insert the lace/elastic

1 To insert the lace/elastic

Insert the lace/elastic correctly by referring to the

illustration. The rollers are opened by pressing rubber

adjusting lever A.

11

11

11

11----2 Lace/elastic guide on the presser foot

2 Lace/elastic guide on the presser foot

2 Lace/elastic guide on the presser foot

2 Lace/elastic guide on the presser foot

Loosen screw A. Adjust the position of the tape guide

according to the needle space and/or width of the tape.

Adjust the position of upper knife guide B according to the

hem width cut by the knife. Install upper knife guide B

by tightening screw C while checking upper knife guide B

does not touch the knife.

11

11

11

11----3 Adjusting the front of the presser foot

3 Adjusting the front of the presser foot

3 Adjusting the front of the presser foot

3 Adjusting the front of the presser foot

Adjust the front of the presser foot according to the type of

fabric and/or elastic to be used.

To sew heavy weight elastic onto the fabric, raise the front

of the presser foot. This reduces resistance and feeds the

fabric smoothly. Loosen nut D and turn screw E as

required.