【

3

】

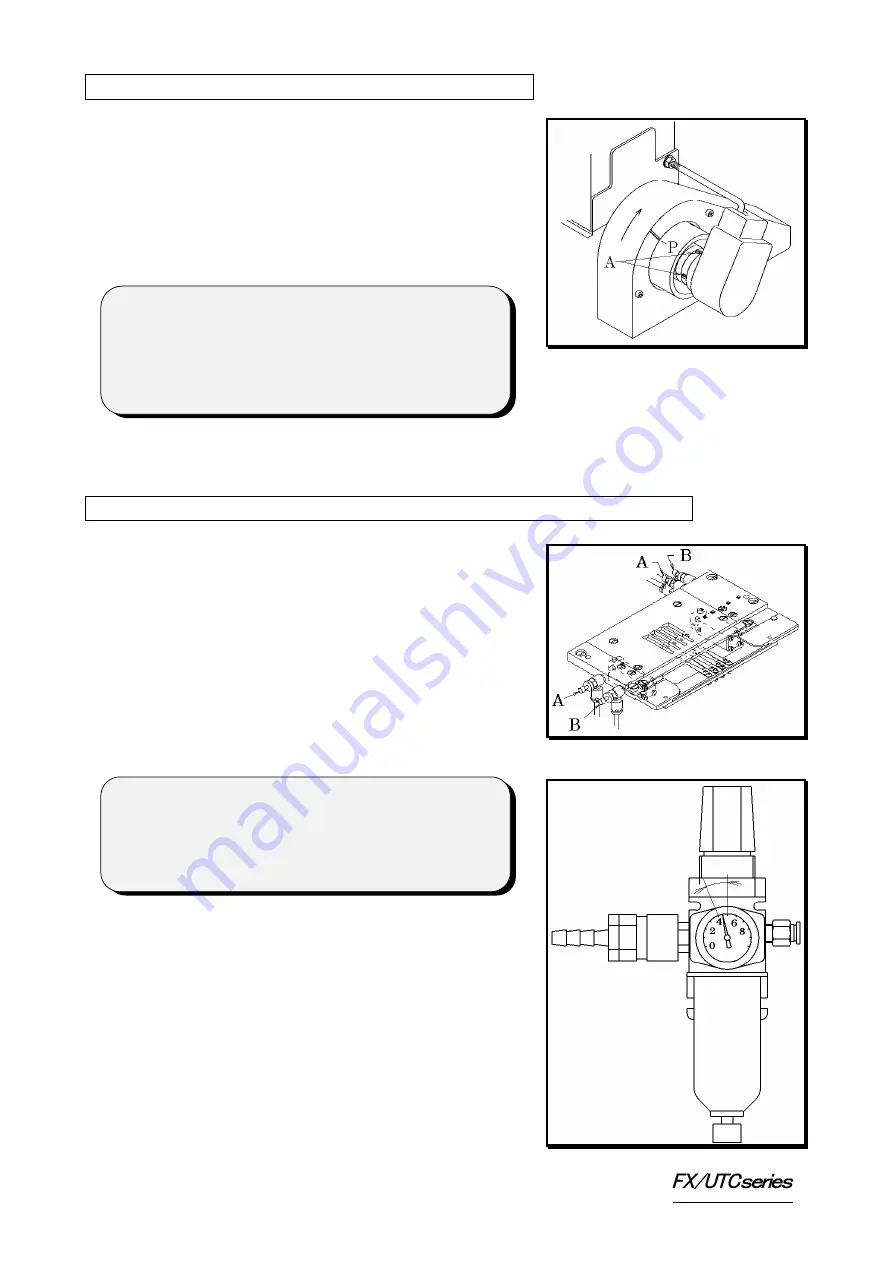

ADJUSTING THE NEEDLE STOP POSITION

Adjust the motor so that the needle bar stops at the

top of its stroke. Then start the machine and check

to see if the needle bar stops at the top of its stroke.

Loosen screws A on the position detector.

Align mark P on the pulley with the alignment mark

on the cover. Then tighten screws A.

Check to make sure again the needle bar stops at

the top of its stroke.

【

4

】

ADJUSTING THE SPEED CONTROLLER AND AIR PRESSURE

Speed controller A controls the speed when the

thread trimming knife holder protrudes.

Speed controller B controls the speed when the

thread trimming knife holder retracts.

If screw A is too loosened, the knife holder will

protrude too fast and then the position of the knife

holder will become unstable, causing cutting errors.

If screw B is too loosened, the knife holder will

retract too fast and then the looper thread may not

be held properly (the speed controllers are

factory-set).

< Note >

Set the regulator at 4~5kg/cm

2

.

To decrease the pressure, turn the adjusting knob

clockwise. Excessive pressure will give a shock to

movable parts and cause damage and trouble.

< Note >

Do not connect the relay cord to the motor until the

stop position of the needle is adjusted.

Check to see if the thread trimmer knife is fully

retracted. Adjust the motor so that the machine

pulley turns clockwise.

3

Summary of Contents for FX/UTC Series

Page 5: ...2 2 FX4406 4412 2...