6-5 Disassembling and reassembling the knife assembly

The knife assembly is secured with four screws F.

Do not loosen other screws.

Perform preventive maintenance such as replacing

the knife by following the procedures below.

1.

Loosen screw H for front cover G.

Disconnect four air lines I.

2.

Loosen four screws F with the needle plate set

screw.

3.

Loosen screw J and remove pin K.

4.

Loosen screw L. Remove presser foot lift lever L.

Loosen screw M. move puller holder assembly

N.

5.

Remove the needle plate as shown in the

illustration.

6.

Reassemble the knife assembly by following the reverse procedures of the above after

performing preventive maintenance.

【

7

】

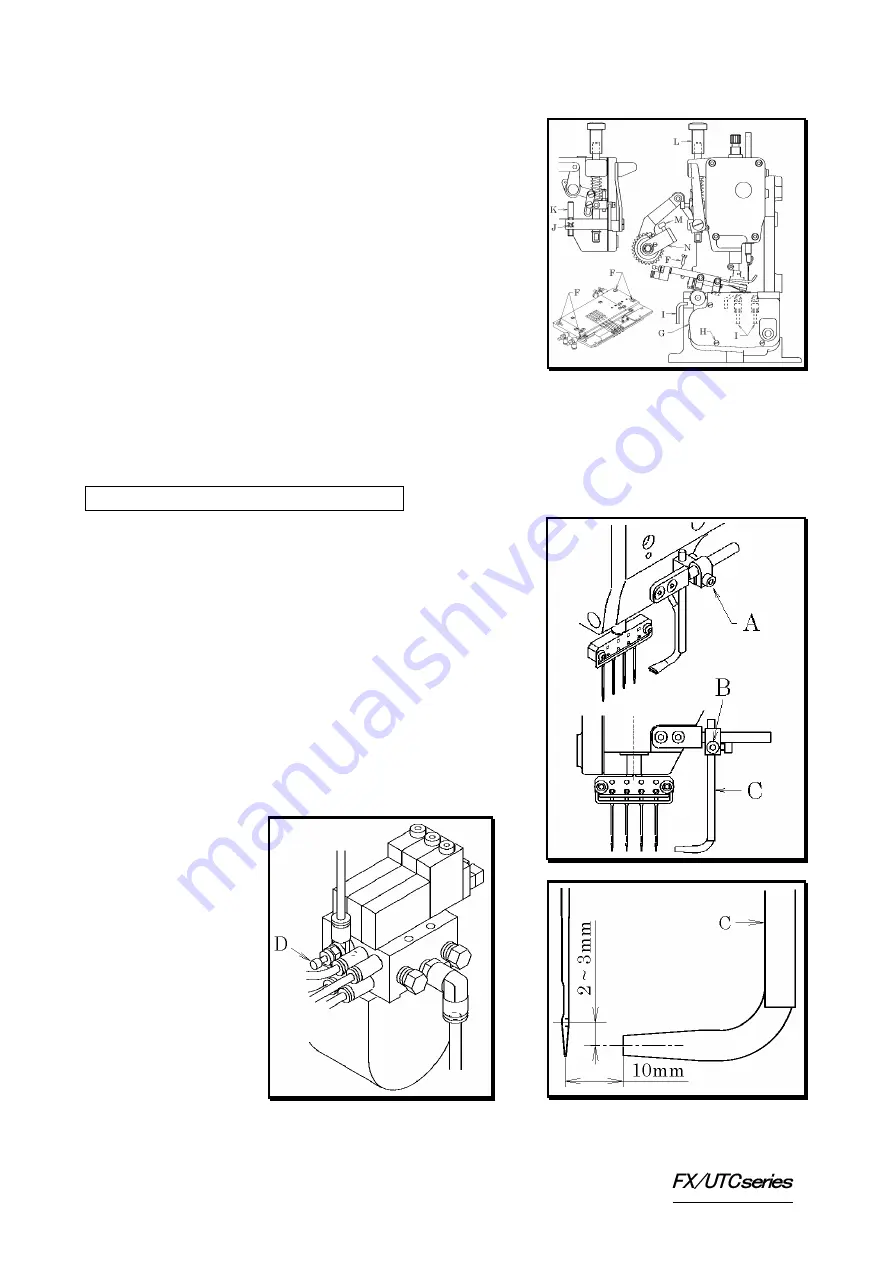

ADJUSTING THE AIR WIPER

The outlet of air wiper C should be positioned

approximately 10mm to the right of the right needle.

Adjustment is made by loosening screw A.

The outlet should be 2~3mm below the eye of the

needle. Adjustment is made by loosening screw B.

The time when the air wiper is blowing is factory-set

at 2 sec. Adjustment can be made by changing the

settings on the motor. Read the instruction

manual for the motor carefully for more information.

The amount of the air should be sufficient to remove

the needle thread from the fabric.

Adjustment is made by turning speed control D as

required (the amount of the air on FX4412P/UTC is

fixed).

6

Summary of Contents for FX/UTC Series

Page 5: ...2 2 FX4406 4412 2...