9

5-7 Changing the amount of the looper font-to-back movement

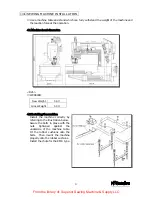

The clearance between the point of the left needle

and the back side of the looper when the looper

moves to the right from the extreme left end of its

travel should be 0.05~0.1mm.

The clearance between the point of the right needle

and the back side of the looper should be 0.2~0.3mm.

The amount of the looper front-to-back movement is

factory-set properly for needle counts 9~11.

If you use needle counts 12~14, adjust the amount

as required (see below).

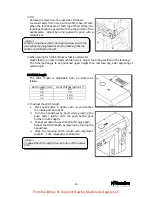

1.

Remove rear bed cover A.

2.

Loosen the nut on the looper front-to-back rod

pin.

To decrease the amount, move the rod pin to X.

To increase the amount, move the rod pin to Y.

The amount range is from 2.3 to 3.1mm.

The amount is factory-set at 2.7 to 2.8mm.

Adjust according to the needle count.

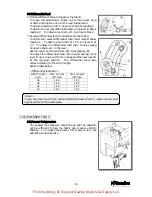

If the amount is excessively decreased, the needle

will rub against the back of the looper, causing

needle breakage. If the amount is excessively

increased, the clearance between the needle and the

back of the looper will increase and then skip

stitching may occur when the looper moves to the

left.

【

6

】

FRONT AND REAR NEEDLE GUARDS

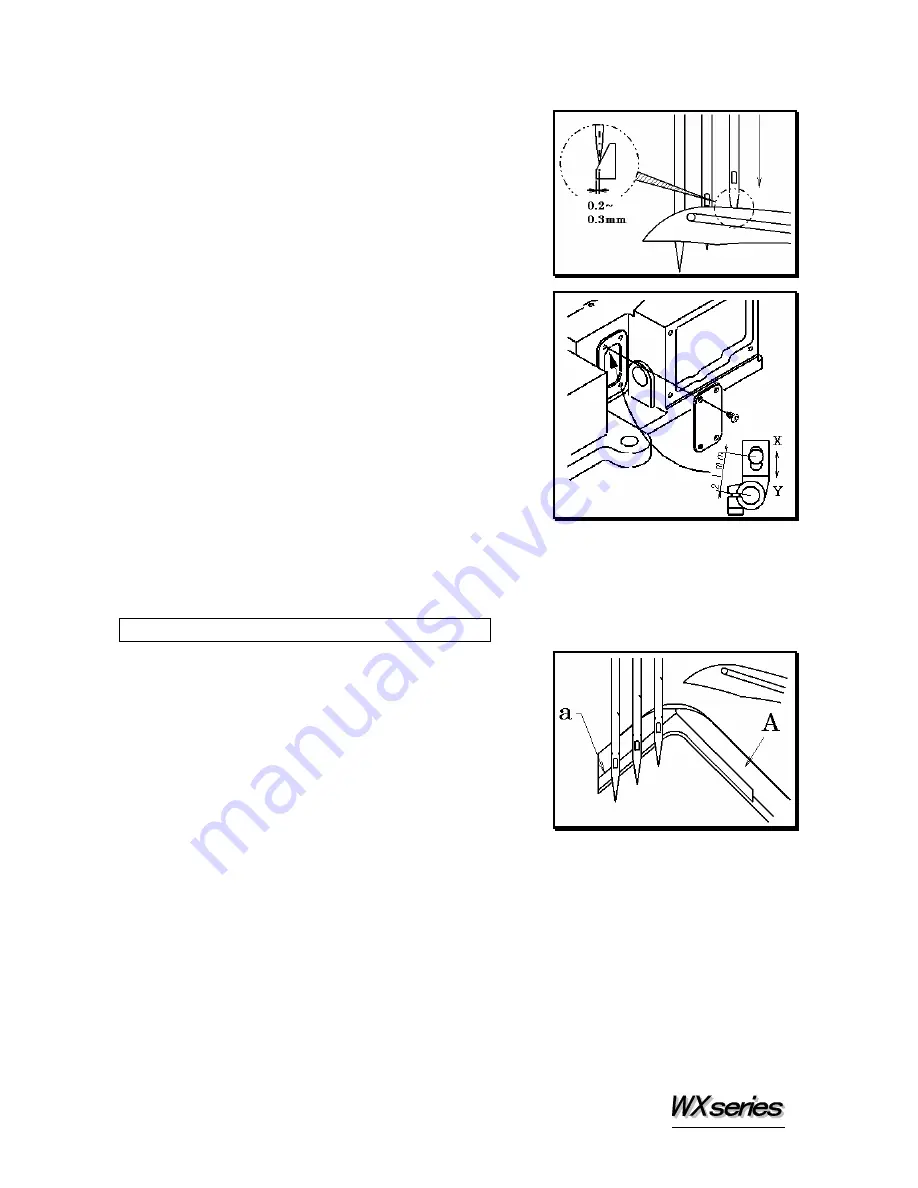

6-1 Position of the needle guard (rear)

Align line (a) on needle guard (rear) A with the

center of the right needle hole when the needle

guard (rear) is at the bottom of the stroke.

When point of the looper passes the back side of the

needles, the needle guard (rear) should push the

right needle slightly toward the front and the

clearance between the point of the looper and the

left needle should be approximately 0.2mm.

From the library of: Superior Sewing Machine & Supply LLC