15

8-3 Differential feed

■

Normal differential feed (to gather the fabric)

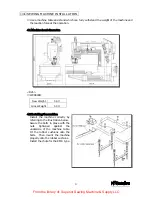

To make this adjustment, loosen nut A, move lever B up

or down and tighten nut A at the required position.

To obtain a feed ratio of 1:1, align lever B with reading C.

To obtain the normal differential feed, raise lever B above

reading C. To obtain a feed ratio of 1:2, set lever B at 2.

■

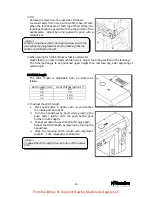

Reverse differential feed (to stretch seam the fabric)

To obtain the reverse differential feed, lower lever B below

reading C. To obtain a feed ratio of 1:0.7, set lever B at

0.7. To adjust the differential feed ratio during sewing

Connect a chain, etc. to the lever.

Set the upper and lower limits with two stoppers (D).

To adjust the differential feed ratio during sewing, move

lever B up or down within this range and then set lever B

at the required position. The differential feed ratio

varies according to the stitch length.

See the table below.

< Differential feed ratio >

Stitch length

(mm)

Max. normal

diff. feed

Max. reverse

diff. feed

3.6

1:1.2

1:0.7

2.5

1:1.6

1:0.7

2.0

1:1.8

1:0.7

1.4

1:2.0

1:0.7

【

9

】

PRESSER FOOT

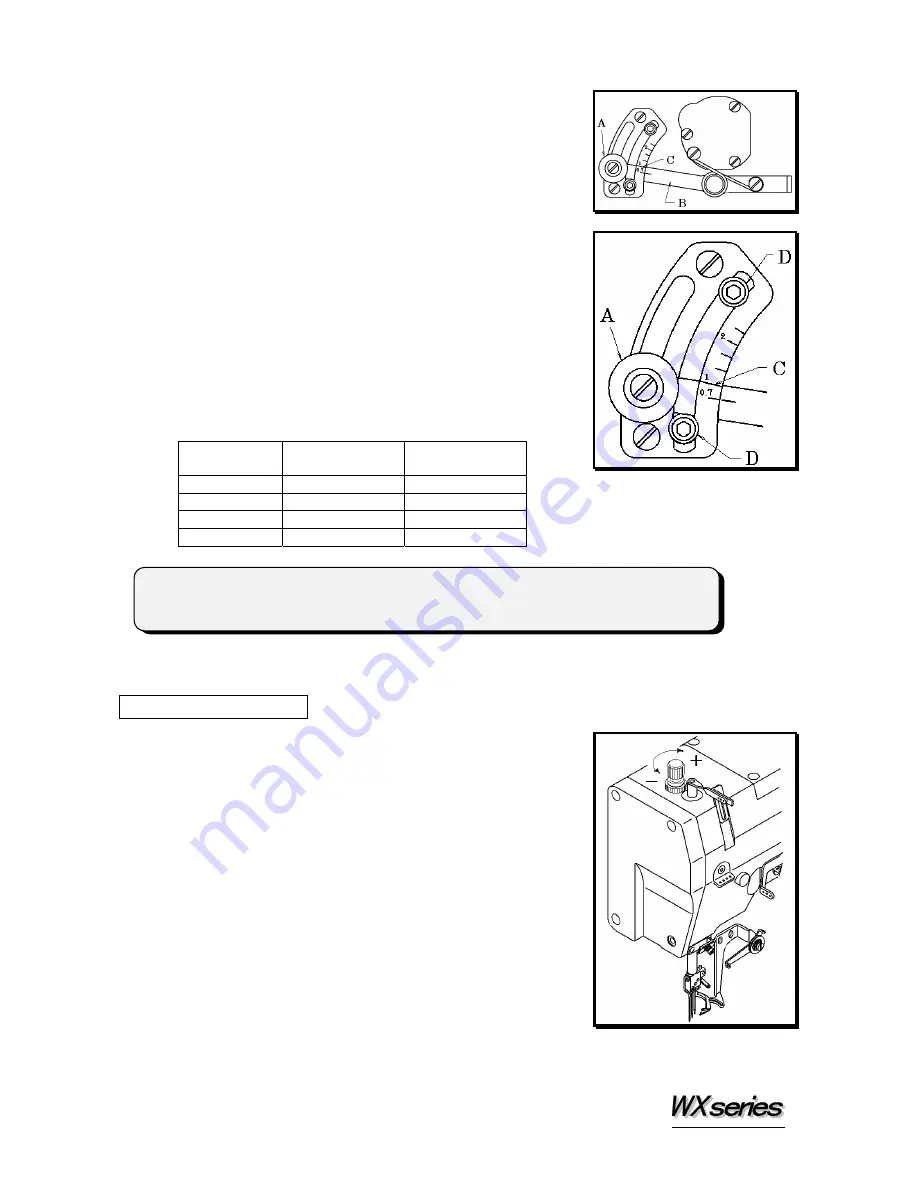

9-1 Presser foot pressure

The presser foot pressure should be as light as possible,

yet be sufficient to feed the fabric and produce uniform

stitches. To increase the presser foot pressure, turn the

adjusting knob clockwise.

< Note >

To use the machine with the normal differential feed, check to make sure the feed

dogs do not touch the needle plate.

From the library of: Superior Sewing Machine & Supply LLC