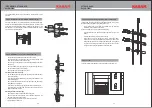

CABLE TERMINATION & SHOCK ABSORBER

Ref. PN 4000

Cable\ Extrimit

Poke\ Pi

STEP 1

STEP 2

STEP 3

STEP 4

è

Insert the cable into the swage tube

è

The swage tube has markings to identify exact positions of crimping

è

Place the swage tube on the hex loc die of a hydraulic crimping

tool(130kN capacity).

è

Ensure that the mark on the swage tube is in the center of the die.

è

Operate the machine to start the swaging operation until the green

light is on.

è

Repeat the process for all markings

13

20

Step 2A : Cable Extremity

è

Insert the cable in to the housing of the cable extremity.

è

Open the strands of the wire.

è

Insert the core of the cable in the poke pin. The strand which is

Straight is the core, the other strands are twisted.

è

With a hollow Centre punch hammer the poke pin deep inside the

housing of the cable extremity.

è

Tighten the connector of the extremity to the housing of the cable

extremity

è

Connect the cable extremity to the universal end extremity Plate

PN 4000 (09) by a locking pin.

è

Insert the pin ring in to the locking pin to lock.

Step 2B : Cable Swaging

è

Insert the connector to the universal extremity plate, PN 4000 (09)

è

Connect the other connector to the tensioner PN4000(03)

è

Apply tension to the cable until the L tension indicator plate touches

the spring

è

Take the shock absorber out of service when the spring is

elongated due to an impact from a fall of the user.

Step 3: Shock Absorber: Ref. PN 4000MU(02)

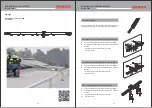

TENSIONER & INTERMEDIATE

Ref. PN 4000

è

Open the threads of the tensioner from both ends. Ensure 75% of

the thread is open.

è

Insert the locking pin so as to pass a the eye of the tensioner and

the Shock Absorber, PN 4000 (07).

è

Insert a pin ring in the locking pin to lock it.

21

è

Insert the cable through the intermediate

è

Connect the intermediate to the receiving structure with the

fastener.

è

The angle of the Intermediate may be changed by inserting the

plastic intermediate fastener to different holes provided.

Step 6 : Intermediate; Ref. PN 4000(10)

Step 4 : Mounting the tensioner on the system

è

Hold the tensioner eye

è

Insert the tensioning tool in the housing of the tensioner and rotate

the tensioner in clock wise direction. Rotate it until reasonable

tension is achieved in the cable and the green indicator rod is visible

in he shock absorber. Stop applying tension when the red indicator

begins to appear in shock absorber

è

Tighten both the chuck nuts

Step 5 : Applying Tension To the line

UPWARD PULL FOR

TENSION