If there are any questions or queries about installation, usage, inspection or maintenance our team would be Happy

to Help. You may please contact us on help@karam.in

Each installation can be viewed by scanning the QR Code on the respective page.

Disclaimer : Illustrations may be changed without notice. All dimensions and specifications are approximate and

drawings not to scale. If in doubt click on the following view the latest updated manual.

Thank you, Together let us make our workforce SAFE.

KARAM is the only company in the world which has a vertically integrated manufacturing set up. Starting with yarn and processing

it to make premium quality of Webbing and Rope, converting hot rolled coils, flats and extrusions of Steel and Aluminium Alloys

into World class Fall Arrest Components.

Over the years KARAM has widened the scope of fall protection to suit workers of most industries including Telecommunications,

Oil & Gas industry, Engineering industry, Power Transmission plants and Construction Industry.

Constant innovation and prime focus on research and design has enabled KARAM to provide Fall protection solutions to a worker

working in some of the most hazardous industrial conditions.

Operations at KARAM are under constant vigilance to provide the finest in Quality of product and service.

FALL PROTECTION EQUIPMENT

MANUFACTURING-

01

Congratulations on your Purchase!

You are now a proud owner of KARAM FIXED LINE SYSTEM and CONGRATULATIONS again that you have

stepped into the business of saving precious lives.

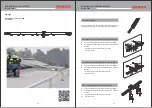

To ensure the fixed line systems lives up to all expectations, it is important to read and comply with this instruction

manual. Please ensure that this manual is easily accessible to all workers working on the lifeline as it is an important

for all personnel installing, using and maintaining the system.

The instruction manual is designed and written to be used for guidance for installation as well as tips on usage and

maintenance of the system.

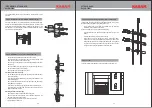

Vertex PN 7000

Vertex PN 4000

Vertex PN 8000

Vertex PN 9000

Horizon PN 5000

Vertical Anchorage Lifeline

System on Rigid Cable Line

Horizontal Anchorage Life

Line System

Vertical Anchorage Lifeline

System on Aluminum Rail System

Mounting Bracket & Rungs

Horizontal Alu-Rail System

Proof loading

Pre-Use Checks

Precautions

Annual Inspection

Tools

Torque Chart

Check Card

INDEX

2-9

10-22

23-35

26-27

28-31

32

33

34

35

36

37

40-41

PRODUCT

CODE

PAGE No.

www.karam.in