– 7

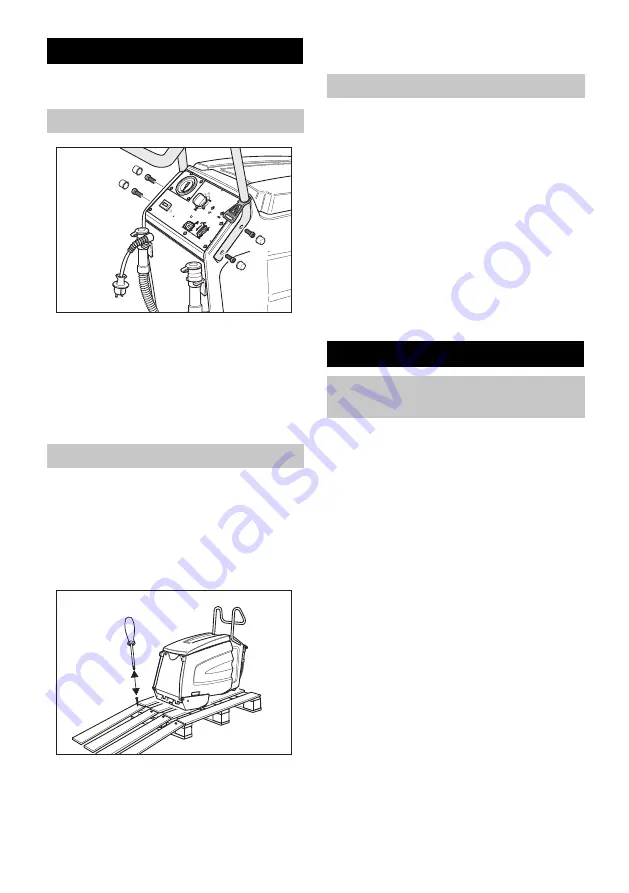

Remove all packaging material ex-

cept the wooden palette.

Insert the pushing handle in the

grooves on the appliance.

Fasten the pushing handle with the

4 screws enclosed in the packet.

Fasten the covering flaps.

Hang in the strain relief clamp at the

pushing handle.

Lock the rear wheels; remove the

wooden blocks used for stopping

the wheels.

Four indicated floor boards of the

pallet are fastened with screws. Un-

screw these boards.

Place the boards on the edge of the

pallet. Place the boards in such a

way that they lie in front of the four

wheels of the machine. Fasten the

boards with screws.

Slowly push the machine down

from the ramp.

Note:

At the time of manufacturing the appli-

ance, it has already been flused using

an anti-frost agent. Before starting the

machine for the first time, you need to

first remove the anti-frost agent.

Fill in 10 litres of fresh water in the

fresh water reservoir.

Press the foot pedal.

Set the machine switch to basic

cleaning.

Keep the machine running until the

pressure on the manometer falls.

DANGER

Risk of injury! The appliance can get

stuck and be dragged away by the

travellator/ escalator. Before starting

cleaning, check the stepping areas and

the ridge profile to see that there are no

deformations or any objects stuck

therein. To be on the safer side, make

sure that you know where the emer-

gency switch-off button of the travella-

tor/ escalator is located.

Cordon off the travellator/ escalator

as long as cleaning operations are

on and the stepping areas are still

wet.

Switch on the travellator/ escalator.

Ensure that the running direction of

the travellator/ escalator is away

from the machine.

Before Startup

Installing the pushing handle

Unloading

Removing anti-frost agents

Start up

Preparing the travellator/

escalator

9

EN

Summary of Contents for BR 35 ESC

Page 1: ...BR 47 35 ESC 59657130 05 15 English 3 Français 20 Español 37 ...

Page 2: ...2 ...

Page 54: ......

Page 55: ......