7

English

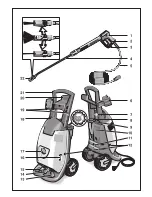

4. Operating the cleaner

Protection from sub-zero temperatures

Caution! Water which has frozen in the cleaner

can destroy parts of it. At best store the cleaner

in a heated room during the winter or empty it or

rinse it thoroughly with antifreeze.

• Empty the cleaner

– Unscrew supply hose and high-pressure hose

from the cleaner.

– Leave the cleaner running until the pump and

lines have emptied (max. 1 minute).

• Putting in antifreeze

For longer intervals between operations,

pumping antifreeze through the cleaner is to be

recommended. By this means also you obtain

a sure protection against corrosion.

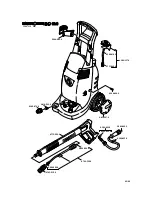

5. Care and maintenance

Every week

• Check oil level in oil reservoir (16): if the oil is

milky (water in oil), seek the help of Customer

Service immediately.

• Clean the strainer at the water outlet.

• Clean the filter at the suction hose for detergent.

Annually or after 500 operating hours

• Change the oil

– For oil quantity and type see Technical

Specifications.

– Undo fastening screws (12), remove unit

cover, remove cover of oil reservoir.

– Lay cleaner on its side and drain oil into

a suitable container.

– Fill slowly with fresh oil; air bubbles have

to escape.

Danger! Before undertaking any care or

maintenance work on the cleaner, pull out the

power plug.

Caution! When changing the oil, dispose of any

waste oil only at authorised collection points.

Safety inspection/maintenance contract

You can arrange with your dealer to have

a regular safety inspection carried out or to have

a maintenance contract. Please seek advice on

this.

Each time before operating the cleaner

• Check connecting cable for damage (risk of

getting an electric shock), have a damaged

connecting cable replaced without delay by

authorised Customer Service personnel or an

electrician.

• Check high-pressure hose for damage

(danger of explosion), replace a damaged high-

pressure hose without delay.

• Check cleaner (pump) for any leaks. Three

drops per minute are allowable and can appear

on the underside of the cleaner. Seek the help

of Customer Service if leaks are more serious.