-

3

–

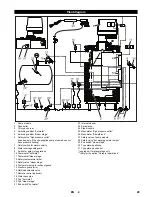

The safety valve protects the high pressure system against

excessive pressure.

–

This valve is set and sealed in the factory. Do not change the

setting.

When the water supply is scarce, the flow switch switches off the

burner.

–

When the water supply is scarce, the flow switch switches off

the burner.

–

Accomodates the switching head during spray jet operations.

–

The flow switch (additional switching head) prevents the burn-

er stage 2 from being switched on during spray jet operations

(approx. 1500 l/h) in order to avoid overheating.

–

The burner stage 1 is released when there is function failure.

The safety temperature limiter switches off the burner when the

maximum permissible steam pressure is exceeded.

–

The safety valve "steam stage" protects the installation

against excessive pressure in the steam stage.

–

This valve is set and sealed in the factory. Do not change the

setting.

The exhaust temperature limiter switches off the burner when the

maximum permissible exhaust temperature is exceeded.

–

When there is a pressure shortfall (1.2 MPa), the pressure

guard switches the operating mode "Operate with steam"

over to "Operate using hot water".

–

The operating mode "Operate with steam" is released only

when the minimum pressure (1.4 MPa) is reached.

–

A main switch that can be locked is to be installed at a safe

and easily accessible place to switch off the entire heating

unit.

–

The main switch is to be switched off while carrying out any

repairs or maintenance jobs.

If a pump module other than the HD 4000 E is used, you must

check if this module has a pressure limit (max. 1.4 MPa). If this is

not the case, you must install an additional safety valve (order no.

6.412-271) at the input.

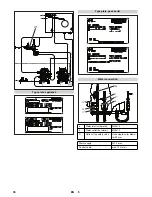

Safety Devices

Safety valve

Safety switch for water scarcity

Water shortage safeguard

Switch head for spray jet operation (with upgrade kit

spray jet only)

Safety temperature limiter (upgrade kit for steam

stage only)

Safety valve "steam stage" (upgrade kit for steam

stage only)

Temperature stop for exhaust gases

Pressure monitor (upgrade kit for steam stage only)

Main switch

Pump module

28

EN

Summary of Contents for HWE 4000

Page 2: ...2 ...

Page 12: ... 10 Maßblatt c Brennkammer ausziehen d Kesselmantel abnehmen 12 DE ...

Page 35: ... 10 Specifications sheet C Pull out the burner chamber d Remove the boiler sleeve 35 EN ...

Page 59: ... 11 Feuille de mesure c Sortir la chambre de brûleur d Enlever le manteau de chaudière 59 FR ...

Page 107: ... 10 Måttblad c Dra ut brännkammare d Ta av behållarens mantel 107 SV ...

Page 131: ... 11 Φύλλο διαστάσεων c Εξαγωγή θαλάμου καύσης d Αφαίρεση μανδύα λέβητα 131 EL ...

Page 155: ... 10 Méret lap c Égéskamrát kihúzni d Kazánburkolatot levenni 155 HU ...

Page 178: ... 10 Přehled rozměrů c Vytažení spalovací komory d Sejmutí pláště kotle 178 CS ...

Page 202: ... 11 Arkusz z wymiarami c Wyjąć komorę spalania d Zdemontować płaszcz kotła 202 PL ...

Page 226: ... 11 Информационный листок с Извлечь топку d Снять обшивку котла 226 RU ...

Page 241: ......