-

11

Danger

Risk of injury on account of electric shock!

–

Before starting any work on the plant, wwitch off the main

switch and ensure that it will not be put on accidentally.

–

Depressurize the system.

–

Work on electrical plant only to be carried out by qualified and

authorised electricians.

Danger

Risk of accident due to improper maintenance!

–

Service and repairs may only be carried out by authorised

persons or Kärcher Customer Service.

–

Adjustments and settings to the regulators and safety equip-

ment may only be carried out by Customer Service.

–

Service and repairs to the gas burner may only be carried out

by authorised Customer Service technicians.

Danger

Risk of injury on account of scalding or burns due to contact with

hot burner parts such as exhaust pipe, burner flange and hot wa-

ter or steam pipes. Let the plant cool down sufficiently before

starting any maintenance or repairs work.

–

Only use accessories and spare parts which have been ap-

proved by the manufacturer. The exclusive use of original ac-

cessories and original spare parts ensures that the appliance

can be operated safely and trouble free.

This is also applicable to the consumables and detergents.

–

Observe all instructions on safety and use which are accom-

panying these parts.

Maintenance and care

Maintenance schedule

Time

Activity

Assembly affected

Performance

of whom

weekly or after

30 operating

hours

opinion

Entire hydraulic installation

Check for leaks.

Operator

opinion

Anti-calcification unit (optional)

Check functioning on the basis of the water hard-

ness values (below 10 °dH).

Operator

opinion

Manometer of the high pressure

pump

Water pressure = reference value?

Operator

Steam jet pressure = reference value?

Operator

opinion

Thermostat "hot water"

Water temperature = reference value?

Operator

Thermostat "steam stage“

Steam jet temperature = reference value?

Operator

opinion

Fuel inlet

Check fuel inlet pipe for leaks and the filter for

cleanliness.

Operator

monthly or after

120 operating

hours

Check function

Safety switch for water scarcity Close water supply, the burner must switch off or

rather not start.

Operator

Replace defective component.

Customer

Service

Check function

Water shortage safeguard

Close water supply, the burner must switch off or

rather not start.

Operator

Replace defective component.

Customer

Service

Check function

Thermostat "hot water“ and

"steam stage“

Check whether the regulator functions properly

in all the three operating modes: Operate with

hot water, spray jet operations, operate with

steam (see chapter "Function").

Operator

opinion

Safety valves

Check for leaks.

Operator

half-yearly or af-

ter 750 operating

hours

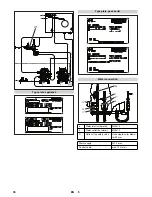

Clean the filter

Heating coil, burner and boiler

parts

Dismantle the burner chamber and the boiler

sleeve using special removing devices and clean

all the parts.

Customer

Service

opinion

Heating coil

Decalcify the heating coil when the pressure in-

creases to more than 10% of the normal value.

Trained op-

erator

opinion

Safety temperature stop, ex-

haust temperature stop, pres-

sure guard (min.)

Check for correct functioning.

Customer

Service

Clean the filter

Burner

Clean depending on the exhaust values (special

soot values).

Customer

Service

opinion

Motor bearing of the burner

Replace if it is making noise; otherwise there will

be some other damages.

Customer

Service

annual

Safety check

Entire high pressure cleaning

unit

Perform a safety inspection as per the applicable

national rules and regulations for liquid spray jets

of the respective country.

Technical

expert

Safety check

Gas installation (only 1.965-101) Perform a safety inspection as per the applicable

national rules and regulations for gas installa-

tions of the respective country.

Technical

expert, gas

supplier

at least every 5

years, recurring

Pressure test

Entire high pressure cleaning

unit

Perform the pressure test as per manufacturer's

instructions.

Technical

expert

36

EN

Summary of Contents for HWE 4000

Page 2: ...2 ...

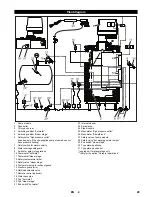

Page 12: ... 10 Maßblatt c Brennkammer ausziehen d Kesselmantel abnehmen 12 DE ...

Page 35: ... 10 Specifications sheet C Pull out the burner chamber d Remove the boiler sleeve 35 EN ...

Page 59: ... 11 Feuille de mesure c Sortir la chambre de brûleur d Enlever le manteau de chaudière 59 FR ...

Page 107: ... 10 Måttblad c Dra ut brännkammare d Ta av behållarens mantel 107 SV ...

Page 131: ... 11 Φύλλο διαστάσεων c Εξαγωγή θαλάμου καύσης d Αφαίρεση μανδύα λέβητα 131 EL ...

Page 155: ... 10 Méret lap c Égéskamrát kihúzni d Kazánburkolatot levenni 155 HU ...

Page 178: ... 10 Přehled rozměrů c Vytažení spalovací komory d Sejmutí pláště kotle 178 CS ...

Page 202: ... 11 Arkusz z wymiarami c Wyjąć komorę spalania d Zdemontować płaszcz kotła 202 PL ...

Page 226: ... 11 Информационный листок с Извлечь топку d Снять обшивку котла 226 RU ...

Page 241: ......