-

18

–

The heating appliance of the machine is an ignition plant.

Please follow the local regulations while installing it.

–

A main switch that can be locked is to be installed at a safe

and easily accessible place to switch off the entire heating

unit.

–

Use only certified chimneys/exhaust pipes.

–

The high pressure cleaning unit is subject to a commissioning

test according to the statutory requirements in the country of

installation.

(see "Installation certification/ Startup testing")

–

The high pressure unit is to be subjected to recurring tests ac-

cording to the statutory requirements in the country of instal-

lation. The test contents and the test frequency are to be

followed according to the pressure appliance directive DGRL

97/23/EG and the national regulations.

(see "Recurring tests")

Note:

Please follow the national and local regulations for:

Electrical installation

Water installation

Heating rooms

Fluid spray jets (for high pressure cleaning units)

Gas installation (in case of gas burners)

Danger

Risk of injury on account of electric shock!

–

The electrical connections must be done by an electrician ac-

cording to IEC 60364-1.

–

The power supply designed for operating the plant must be

suitable for continuous operations.

–

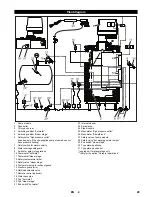

Provide a emergency stop switch after fuse 1 x 10A (neutral).

Install the emergency stop switch at the entrance door to the

heating room (see circuit plan).

According to the applicable regulations, the appliance

must never be used on the drinking water supply without

a system separator. Use a suitable system separator

manufactured by KÄRCHER; or, as an alternative, a

system separator as per EN 12729 Type BA. Water flowing

through a system separator is considered non-drinkable.

Caution

Always connect the system separator to the water supply, never

directly to the appliance!

Install stop-valves in the water inlets.

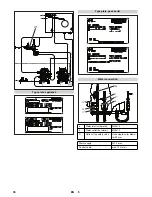

Install a movable pressure hose between the connection to

the water supply network and the (high pressure) cleaning

unit.

Design the water supply for continuous operations.

–

Install the high pressure/ hot water plant in a safe dry atmos-

phere and in a way that these can be accessed easily for re-

pairs and maintenance.

–

The ambient temperature must be below 40 °C.

–

Provide adequate space for maintenance and repairs jobs.

–

Provide water drainage for the safety valves and for the plant

during maintenance jobs.

–

Lay the exhaust pipe between the hot water generator and

the chimney in such a way that it is short and there is easy

flow.

–

Design the chimney cross-section according to the max. ther-

mal output.

–

Hang the general operating instructions in the heating room

so that they are easily visible.

If the design of the heating room is subject to "Heating room

guidelines", then you need to prepare an installation report with

the following contents:

–

Shortcomings in installing the danger switch, the main gas

shut-off system and the ventilation/ exhaust systems.

–

Results of the leakage tests in the boiler firing system.

–

Signature of the plant operator or his representative.

–

On continuous on-demand heaters, the safety valve must be

installed in the immediate vicinity of the boiler end.

–

The clearance between the connection pipe section and the

safety valve must be at least as large as the entry cross sec-

tion of the safety valve.

–

Use only those installation materials that are permitted for use

for the expected operating pressure.

–

Install a movable high pressure hose between the building-

side high pressure pipe and the high pressure cleaning unit.

–

As far as possible, lay the high pressure pipes straight and

rinse them thoroughly before startup.

–

Provide for heat expansion and effects of pressure. Use

dead-beat loose and fixed clamps.

–

The pipes used for fuel supply (heating oil or gas) are to be

installed according to the applicable regulations.

Installing the plant

The plant may only be installed by authorised

technicians!

General

Specifications, guidlines and regulations for installa-

tion

Electrical installation

Water installation

Heating rooms

Safety valve

High pressure installation

43

EN

Summary of Contents for HWE 4000

Page 2: ...2 ...

Page 12: ... 10 Maßblatt c Brennkammer ausziehen d Kesselmantel abnehmen 12 DE ...

Page 35: ... 10 Specifications sheet C Pull out the burner chamber d Remove the boiler sleeve 35 EN ...

Page 59: ... 11 Feuille de mesure c Sortir la chambre de brûleur d Enlever le manteau de chaudière 59 FR ...

Page 107: ... 10 Måttblad c Dra ut brännkammare d Ta av behållarens mantel 107 SV ...

Page 131: ... 11 Φύλλο διαστάσεων c Εξαγωγή θαλάμου καύσης d Αφαίρεση μανδύα λέβητα 131 EL ...

Page 155: ... 10 Méret lap c Égéskamrát kihúzni d Kazánburkolatot levenni 155 HU ...

Page 178: ... 10 Přehled rozměrů c Vytažení spalovací komory d Sejmutí pláště kotle 178 CS ...

Page 202: ... 11 Arkusz z wymiarami c Wyjąć komorę spalania d Zdemontować płaszcz kotła 202 PL ...

Page 226: ... 11 Информационный листок с Извлечь топку d Снять обшивку котла 226 RU ...

Page 241: ......