English

15

Note

The fuel cock is supplied from the factory

open. If the machine has been out of use for

a longer period of time, open the fuel cock.

Î

Open the device hood and secure it us-

ing the hood support.

1

Fuel tap

Î

Push lever in "ON" direction.

Î

Close cover.

Î

Release the drawbar.

Î

Pull out the choke lever.

Î

Turn ignition key past position 1.

Î

If the machine starts, release the igni-

tion key.

Î

Once the engine is running, re-insert the

choke lever.

Note

Never operate the starter motor for longer

than 10 seconds. Wait at least 10 seconds

before operating the starter motor again.

Î

You can use the accelerator to regulate

the engine speed.

The beacon light increases the attention of

others in the traffic towards the appliance

and the operator.

1

Switch

Î

Switch on the beacon light.

Î

Pull the unlock/ brake lever and move

the drawbar cautiously towards the

front.

Î

Pull the unlock/ brake lever and move

the drawbar cautiously towards the rear.

Note

Driving method

–

You can release the unlock/ brake lever

if the drawbar is not in the central posi-

tion.

–

The drawbarl can be used to regulate

the driving speed infinitely.

–

Avoid pressing the drawbar suddenly as

this may damage the hydraulic system.

–

In the event of power loss on inclined

surfaces, slightly reduce the pressure

on the drawbar.

Î

Direct the device in the desired direction

using the drawbar.

Î

Release the drawbar; the machine

brakes automatically and stops.

Driving over fixed obstacles which are 50

mm high or less:

Î

Drive forwards slowly and carefully.

Driving over fixed obstacles which are more

than 50 mm high:

Î

Only drive over these obstacles using a

suitable ramp.

Note

During operations, the waste container

must be emptied at regular intervals or re-

placed through an empty waste container.

Î

In appliances with the leaf blower at-

tachment set: Open Exhaust openings

for vacuuming.

Î

Pull the suction pipe from the holder and

hold it at the handle.

Î

Suck off dirt using the suction pipe.

Î

Insert the suction pipe back into the

holder after vacuuming.

Garbage that is too big for the suction pipe

can be thrown into the bulk waste flap.

Î

Tilt the bulk waste flap upwards and

throw in the garbage.

Î

Close the bulk waste flap.

Î

Close exhaust openings for vacuuming.

Î

Pull the blower pipe out of the holder.

Î

Use the air jet from the blower pipe to

blow the leaves in the desired direction.

Î

Insert the blower pipe back into the

blower after vacuuming and open the

ventilation louvers for suction operation.

The fine dust filter must be cleaned when

the vacuuming performance diminishes

and before removing the waste container.

Î

Move the filter cleaning handle back

and forth and couple of times and wait

till the dust has settled down in the

waste container.

Note

Wait till the dust has settled down before re-

moving the garbage sack.

Î

Stop the machine.

Î

Turn the ignition key to 0 position.

Î

Tilt the suction head upward.

Î

Pull out the cover from the garbage

sack by holding it at the two holder

loops.

Î

Close the mouth of the garbage sack

and take it out of the garbage container.

Note

Wait till the dust has settled down before re-

moving the waste container.

Î

Stop the machine.

Î

Turn the ignition key to 0 position.

Î

Tilt the suction head upward.

Î

Close the waste container lid.

Î

Pull the waste container backwards out

of the device.

Note

You can remove the waste container, emp-

ty it and re-insert it or replace it through an-

other, empty waste container.

Î

Tilt the suction head upward.

Î

Insert the waste container into the appli-

ance.

Î

Open the waste container lid.

Î

Tilt down the suction head.

Î

Check whether the washers of the suc-

tion head are sealing properly.

Note

You can use all standard waste containers

according to DIN EN 840-1 with 240 litre ca-

pacity. It may be necessary to slightly adjust

the intake due to the manufacturer's toler-

ances.

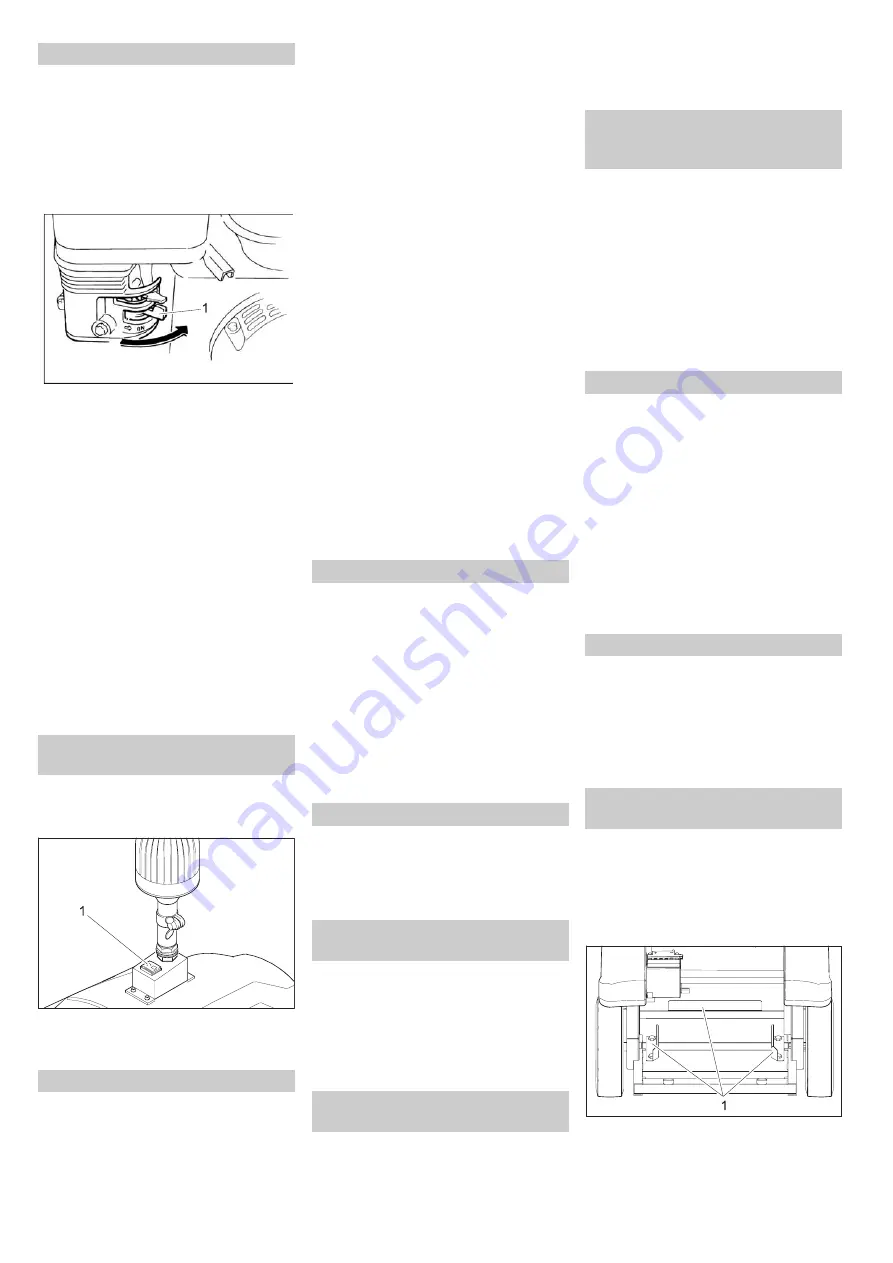

1

Stopper

Î

Loosen the fastening screws of the

stopper.

Starting the machine

Open fuel cock

Turning on the Appliance

Setting the motor rpm

Switch on beacon light (only with

accessory beacon light kit)

Drive the machine

Drive forward

Reverse drive

Steering

Brakes

Driving over obstacles

Vacuuming

Throwing in bulk waste

Blowing (only using the Leaf Blower

attachment set)

Cleaning the fine dust filter (only

Fine dust filter attachment set)

Removing the garbage sack (only

with the garbage sack accessory

kit)

Removing the waste container

Insert waste container

Adjusting the intake for the waste

container

Summary of Contents for IC 15/240 W

Page 1: ...Deutsch 3 English 12 IC 15 240 W 5 962 627 0 2018690 08 07...

Page 2: ...2...

Page 21: ......