16

English

Î

Insert the waste container with open lid

into the device.

Î

Tilt down the suction head.

Î

Align the waste container in such a way

that the suction head seals off from all

direction.

Î

Move the stoppers to touch the contain-

er and tighten the fastening screws.

1

Fastening screw of suction head

Î

Loosen the fastening screws of the suc-

tion head on both the sides.

Î

Press the suction head on to the waste

container and tighten the fastening

screws at the same time.

Î

Lock the parking brakes by releasing

the drawbar.

Î

Turn ignition key to "0" and remove it.

몇

Warning

In general, when shipping the machine, the

freewheel lever must be engaged in the up-

per position. Only once this has been done,

will the travel drive be ready for operation.

The machine must always be moved up or

down slopes by engaging self-propulsion.

Î

Lock the parking brakes by releasing

the drawbar.

Î

Turn ignition key to "0" and remove it.

Î

Empty tank. Draw off fuel using suitable

pump.

Î

Secure the wheels of the machine with

wheel chocks.

Î

Secure the machine with tensioning

straps or cables.

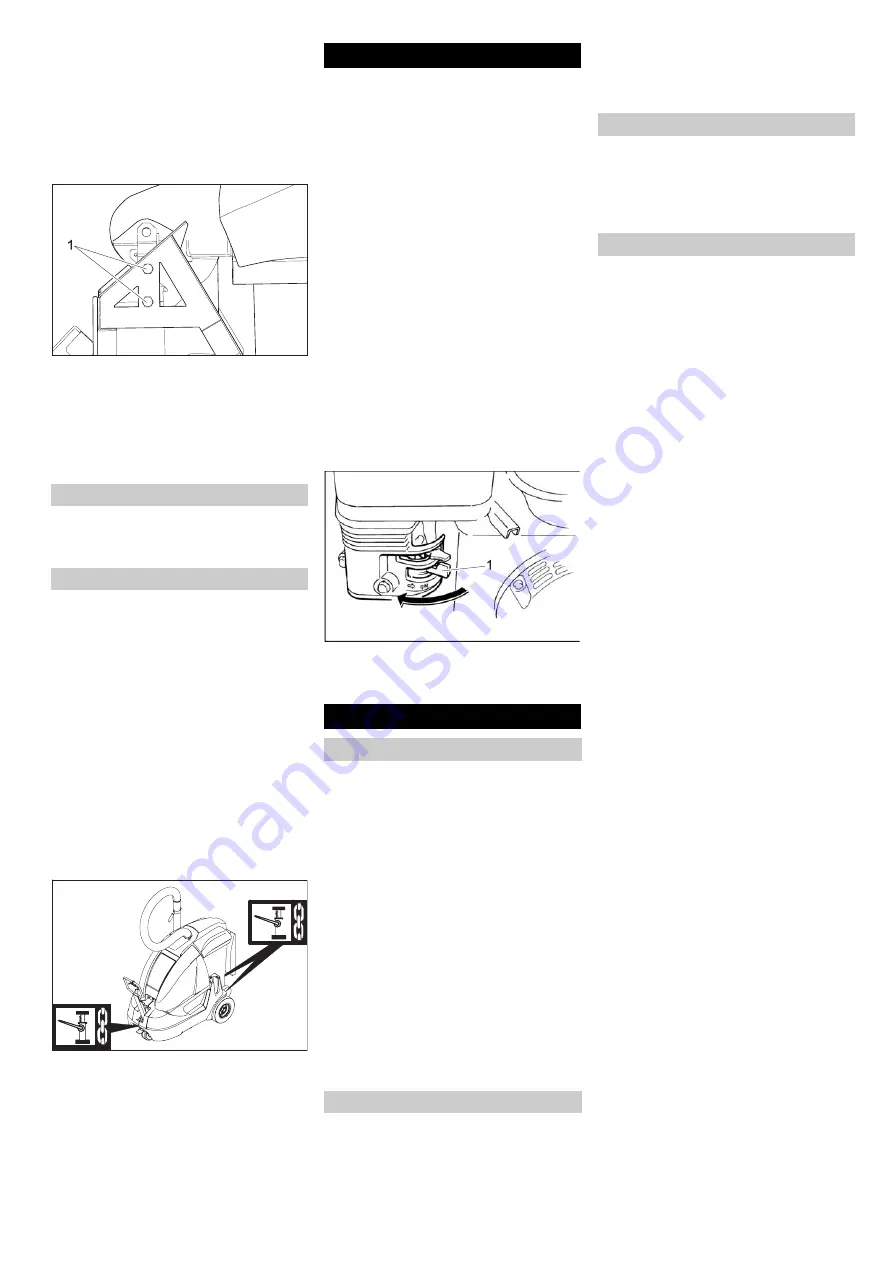

Note

Observe markings for fixing points on base

frame (chain symbols). When loading or un-

loading the machine, it may only be operat-

ed on gradients of max. 18%.

If the device is going to be out of service for

a longer time period, observe the following

points:

Î

Park the machine on an even surface.

Î

Lock the parking brakes by releasing

the drawbar.

Î

Fill fuel tank and close fuel cock.

Î

Change engine oil.

Î

Turn ignition key to "0" and remove it.

Î

Unscrew spark plugs and pour approx.

3 cm³ of oil into the spark plug hole.

Crank the engine several times before

replacing the spark plug. Screw in the

spark plug.

Î

Clean the inside and outside of the ma-

chine.

Î

Park the machine in a safe and dry place.

Î

Disconnect battery.

Î

Charge battery approx. every 2 months.

Î

Open the device hood and secure it us-

ing the hood support.

1

Fuel tap

Î

Push lever in "OFF" direction.

Î

First switch off the appliance and re-

move the ignition key before performing

any cleaning or maintenance tasks on

the appliance, replacing parts or switch-

ing over to another function.

Î

Pull out the battery plug or clamp the

battery while working on the electrical

unit.

–

Maintenance work may only be carried

out by approved customer service out-

lets or experts in this field who are famil-

iar with the respective safety

regulations.

–

Mobile appliances used for commercial

purposes aer subject to safety inspec-

tions according to VDE 0701.

–

Do not clean the appliance with a water

hose or high-pressure water jet (danger

of short circuits or other damage).

Danger

Risk of injury! Wear dust mask and protec-

tive goggles.

Î

Open the device hood and secure it us-

ing the hood support.

Î

Clean machine with a cloth.

Î

Blow through machine with compressed

air.

Î

Close cover.

Î

Clean the machine with a damp cloth

which has been soaked in mild deter-

gent.

Note

Do not use aggressive cleaning agents.

Note

The elapsed-time counter shows the timing

of the maintenance intervals.

Daily maintenance:

Î

Check engine oil level.

Î

Check axle drive oil level.

Î

Check tyre pressure.

Î

Check function of all operator control el-

ements.

Î

Clean seal on suction head and large

dirt flap.

Weekly maintenance:

Î

Check fuel pipes for leaks.

Î

Check air filter.

Î

Check moving parts for freedom of

movement.

Maintenance to be carried out every 100

operating hours:

Î

Check fuel pipes for leaks.

Î

Change engine oil (initial change after

20 operating hours).

Î

Check spark plug.

Î

Check battery acid level.

Î

Check status of the brake springs and

ensure that they are fitting properly.

Î

Check tension, wear and function of

drive belts (V-belt and circular belt).

Î

Check the tension of the drive chains.

For description, see section on Mainte-

nance work.

Note

Where maintenance is carried out by the

customer, all service and maintenance

work must be undertaken by a qualified

specialist. If required, a specialised Archer

dealer may be contacted at any time.

Maintenance to be carried out after 20 op-

erating hours:

Î

Carry out initial inspection.

Maintenance to be carried out every 100

operating hours

Maintenance to be carried out every 200

operating hours

Maintenance to be carried out every 300

operating hours

Note

In order to safeguard warranty claims, all

service and maintenance work during the

warranty period must be carried out by the

authorised Kärcher Customer Service in

accordance with the maintenance booklet.

Turn off the appliance.

Transport

Shutdown

Close fuel cock

Maintenance and care

General notes

Cleaning the inside of the machine

External cleaning of the appliance

Maintenance intervals

Maintenance by the customer

Maintenance by Customer Service

Summary of Contents for IC 15/240 W

Page 1: ...Deutsch 3 English 12 IC 15 240 W 5 962 627 0 2018690 08 07...

Page 2: ...2...

Page 21: ......