English

17

Preparation:

Î

Park the machine on an even surface.

Î

Lock the parking brakes by releasing

the drawbar.

Î

Turn ignition key to "0" and remove it.

Danger

Risk of injury due to engine overrun. Once

the engine has been switched off, wait for 5

seconds. Stay well clear of the working area

for this time.

Î

Allow the machine sufficient time to cool

down before carrying out any mainte-

nance and repair work.

Do not touch any hot parts, such as the

drive motor and exhaust system.

Please observe the following warning notes

when handling batteries:

Danger

Risk of explosion! Do not put tools or similar

on the battery, i.e. on the terminal poles and

cell connectors.

Danger

Risk of injury! Ensure that wounds never

come into contact with lead. Always clean

your hands after having worked with batter-

ies.

Î

Tilt the suction head upward.

Î

Close the waste container lid.

Î

Pull the waste container backwards out

of the device.

Î

Insert battery in battery mount.

Î

Lay the holder belt around the battery

and tighten it.

Î

Connect pole terminal (red cable) to

positive pole (+).

Î

Connect pole terminal to negative pole

(-).

Note

Before removing the battery, make sure

that the negative pole lead is disconnected.

Check that the battery pole and pole termi-

nals are adequately protected with pole

grease.

Danger

Risk of injury! Comply with safety regula-

tions on the handling of batteries. Observe

the directions provided by the manufacturer

of the charger.

Î

Disconnect battery.

Î

Connect positive terminal cable from

the charger to the positive pole connec-

tion on the battery.

Î

Connect negative terminal cable from

the charger to the negative pole con-

nection on the battery.

Î

Plug in mains connector and switch on

charger.

Î

Charge battery using lowest possible

level of charging current.

몇

Warning

Regularly check the fluid level in acid-filled

batteries.

Î

Unscrew all cell caps.

Î

Where fluid level is too low, top up cells

to the mark provided with distilled water.

Î

Charge battery.

Î

Screw in cell caps.

Danger

Risk of injury!

Î

Park the machine on an even surface.

Î

Lock the parking brakes by releasing

the drawbar.

Î

Remove ignition key.

Î

When carrying out repairs on public

highways, wear warning clothing when

working close to passing traffic.

Î

Check stability of ground. Also secure

the machine with wheel chock(s) to pre-

vent it rolling away.

Check tyres

Î

Check tyre contact face for foreign ob-

jects.

Î

Remove objects found.

Î

Use suitable, commercially available

materials to carry out tyre repairs.

Note

Observe the manufacturer's recommenda-

tions. The journey may be resumed provid-

ing that the directions supplied by the

product manufacturer have been observed.

The tyre/wheel change should nonetheless

be carried out as soon as possible.

Î

Loosen wheel nuts.

Î

Position vehicle jack at the appropriate

mounting point for the front or rear

wheel.

Î

Raise machine using vehicle jack.

Note

Use a suitable commercially available vehi-

cle jack.

Î

Remove the wheel nuts; unscrew the

axle at the front wheel.

Î

Remove wheel.

Î

Mount spare wheel.

Î

Screw on wheel nuts.

Î

Lower machine using vehicle jack.

Î

Tighten wheel nuts.

몇

Warning

The engine is equipped with an oil deficien-

cy switch. When the fill level is insufficient,

the engine switches off and can only be re-

started once the engine oil has been replen-

ished.

Danger

Risk of burns!

Î

Allow engine to cool down.

Î

Wait for at least 5 minutes after switch-

ing off the engine before checking the

engine oil fill level.

Î

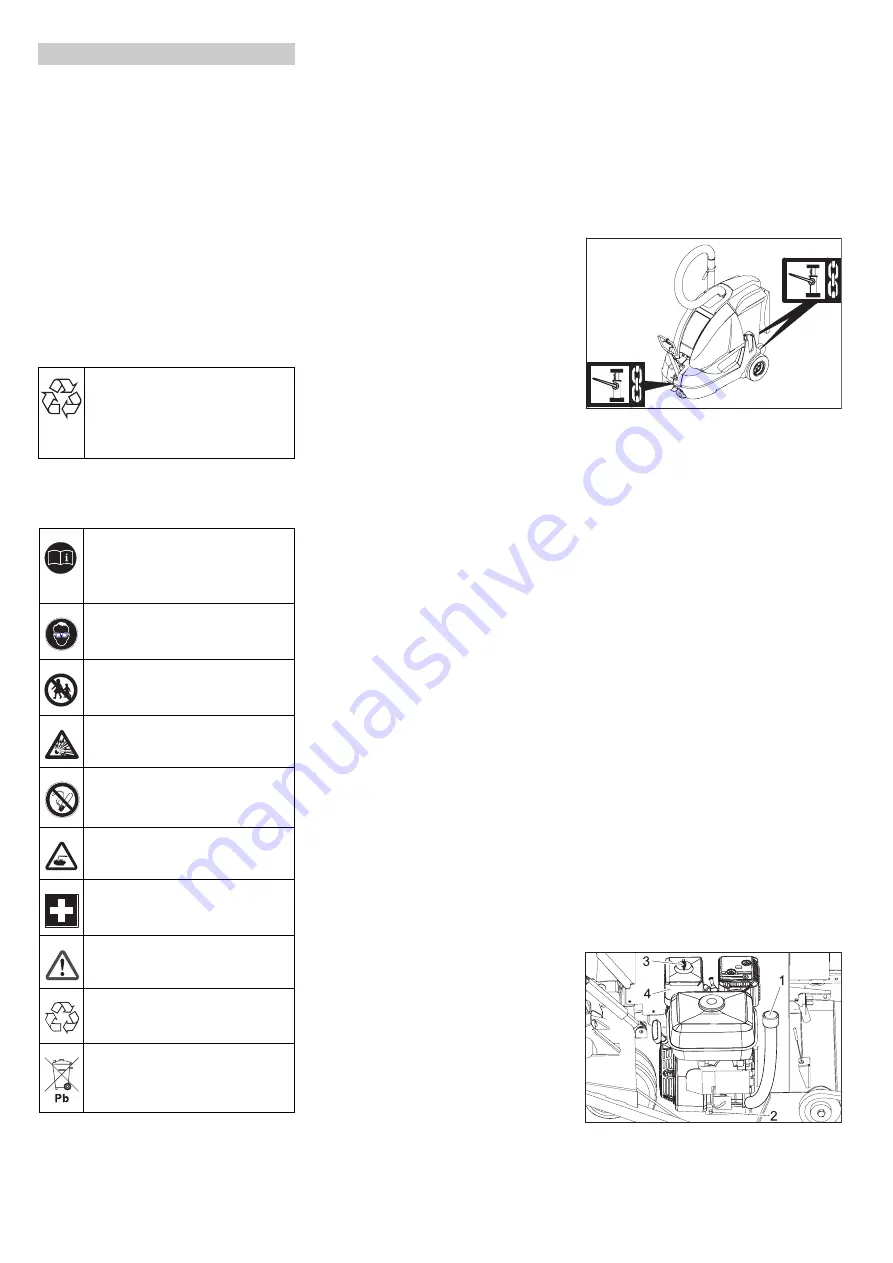

Open the device hood and secure it us-

ing the hood support.

1

Oil dipstick

2

Oil drain screw

3

Wing nut

4

Air filter

Maintenance Works

General notes on safety

Please do not release engine oil,

fuel oil, diesel and petrol into the

environment Protect the ground

and dispose of used oil in an en-

vironmentally-clean manner.

Safety notes regarding the batteries

Observe the directions on the bat-

tery, in the instructions for use

and in the vehicle operating in-

structions

Wear eye protection

Keep children away from acid and

batteries

Danger of explosion

Fire, sparks, naked flames and

smoking must be strictly avoided

Danger of chemical burns

First aid

Warning note

Disposal

Do not throw the battery into the

regular waste

Installing and connecting the battery

Charging battery

Check fluid level in the battery and ad-

just if required

Replacing wheel

Check engine oil level and top up, if re-

quired

Summary of Contents for IC 15/240 W

Page 1: ...Deutsch 3 English 12 IC 15 240 W 5 962 627 0 2018690 08 07...

Page 2: ...2...

Page 21: ......