Operating instructions

KM 100/100 R / KM 100/100 R P

English

28

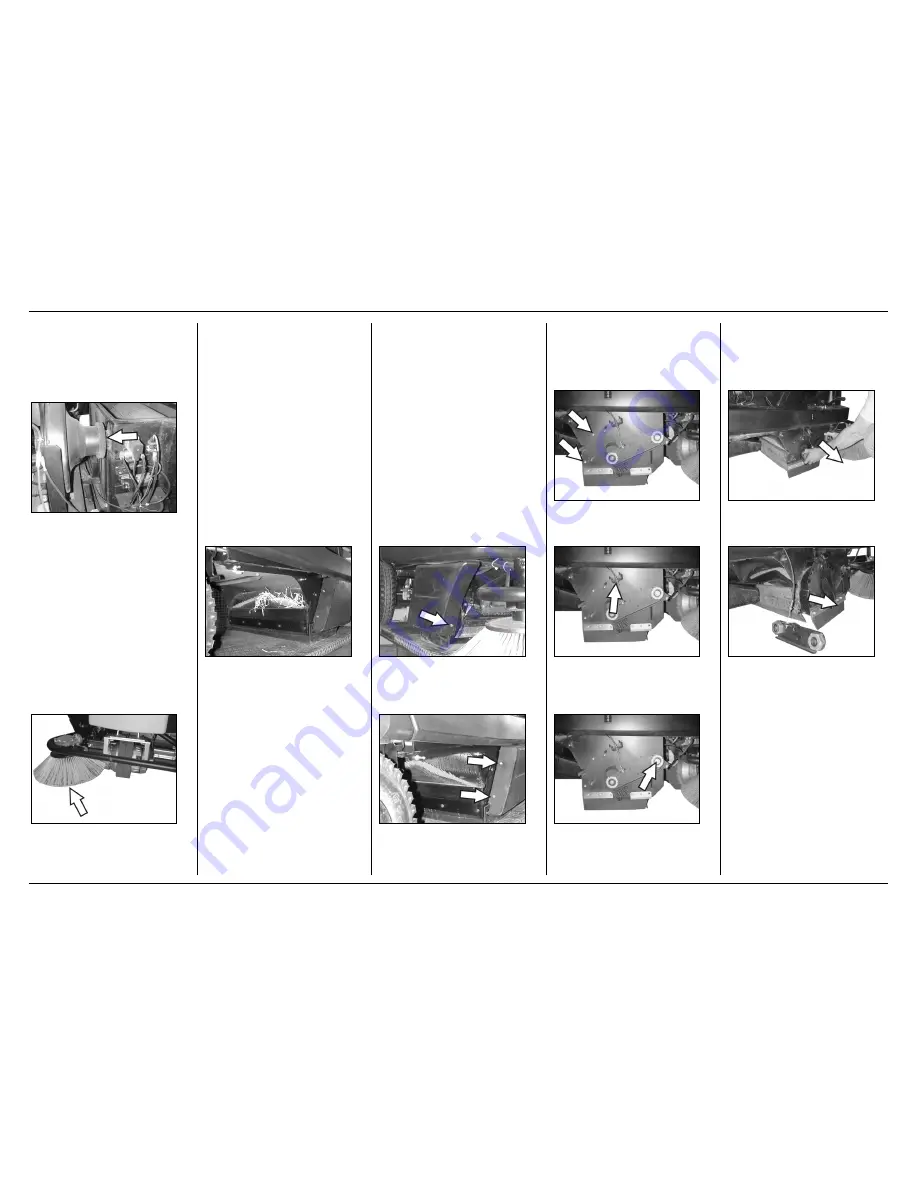

Checking the sealing cup

!

The sealing cup must be

regularly checked for a proper fit.

Sealing cup at the suction turbine

Replacing side brush

!

Unscrew fastening screws

(3 pieces) at the underside

!

Slip side brush on carrier and

screw it tight

Check the sweep roller

!

Stand sweeper on a flat surface

!

Raise the sweep roller

!

Turn key switch to "0" and

remove key

!

Secure the machine against

rolling away using a wedge

!

Remove the debris container

from both sides of the unit

!

Remove tapes and string from

the sweep roller

Replace the sweep roller

—

Replacing it is necessary when

the sweeping effect visibly

deteriorates due to wear of the

bristles.

!

Stand sweeper on a flat surface

!

Raise the sweep roller

!

Turn key switch to "0" and

remove key

!

Secure the machine against

rolling away using a wedge

!

Remove the debris container

from both sides of the unit

!

Unscrew front screw of right side

panellint

!

Unscrew rear screws of right side

panelling

!

Unscrew screws

!

Loosen fastening screw of the

bowden cable and unhitch the

cable

!

Unscrew the screw at the fulcrum

of the main brush rocker arm

!

Pull off the main brush rocker

arm

!

Lift off cover and remove main

brush