English

67

10.7 Maintenance work

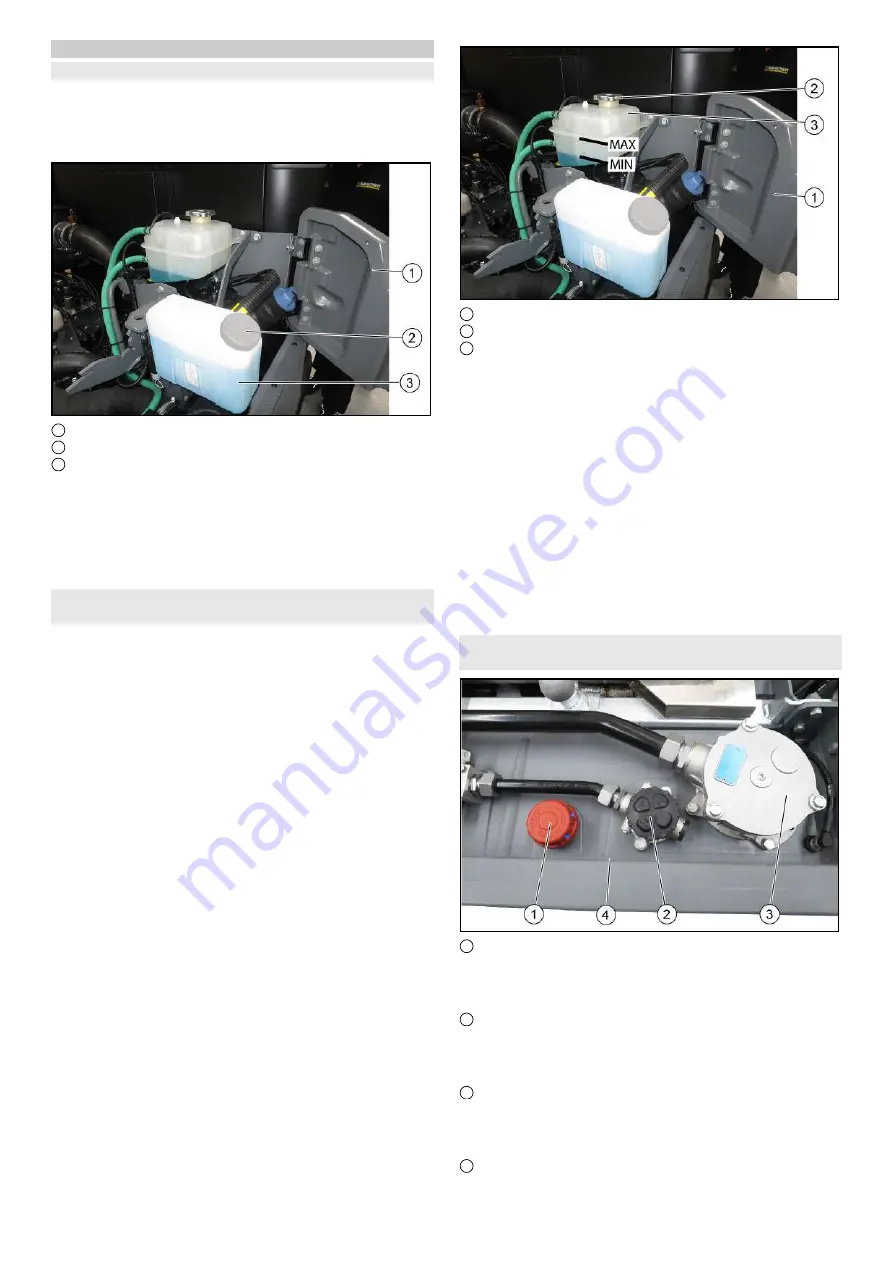

10.7.1Filling the wiping water container

Note

Observe the manufacturer's specifications for wiping water

fluid and antifreeze. Do not mix antifreeze with other anti-

freeze.

1

Right-hand service flap

2

Lock

3

Wiping water container

1. Open the right-hand service flap.

2. Open the cap on the wiping water container.

3. Fill with r water liquid.

a If there is a risk of frost, add antifreeze according to

manufacturer's instructions.

4. Close the cap on the wiping water container.

10.7.2Checking the coolant level and topping up the

coolant

몇

CAUTION

Risk of burns on account of hot components

Do not open or touch the radiator or parts of the cooling

system while the motor is hot.

몇

CAUTION

Risk of injury due to pressurised cooling system

Carefully open the expansion tank (2 levels).

ATTENTION

Material damage due to incorrect coolant

Top up the coolant only when the engine is cold.

The water/antifreeze mixing ratio should be 60:40 to 50:50.

This usually corresponds to frost protection from -25 °C to

-40 °C.

The minimum mixing ratio should be 70:30 and the maxi-

mum mixing ratio 40:60. Further increasing the proportion

of antifreeze (e.g. 30:70), does not further improve the

freezing point.

The mixture of the coolant shall consist of deionised or dis-

tilled water and of radiator protection according to stand-

ards ASTM D 3306 Type 1 monoethylene glycol-based

with addition of organic inhibitors.

For coolant, see chapter "Technical data".

1

Right-hand service flap

2

Lock

3

Expansion reservoir

1. Check the filling level when the engine is cold.

2. Open the right-hand service flap.

3. Check the filling level in the expansion reservoir.

Note

The correct coolant level must be between MAX and

MIN. In case of severe loss of coolant, carry out trouble-

shooting and correct any faults found.

4. Top up the coolant if necessary.

Add coolant

5. Turn the cap of the expansion tank to open and remove

it.

6. Add approved coolant to expansion tank to top marking

(MAX).

7. Fit the cap of the expansion tank and tighten.

8. Close the service flap.

10.7.3Checking the hydraulic oil level and topping up

the hydraulic oil

1

Screw-in lid with air filter

Note

Replace the air filter annually or every 1000 hours of oper-

ation

2

Hydraulic oil filter

Note

May only be replaced by customer service according to the

inspection checklist (ICL)

3

Hydraulic oil filter

Note

May only be replaced by customer service according to the

inspection checklist (ICL)

4

Hydraulic tank

Summary of Contents for MC 250

Page 2: ......