16

English

PRIOR TO INITIAL START-UP

Directions for unloading

!

Do not use a fork-lift truck for unloading the

sweeper as the sweeper can sustain damage

in this way.

The sweeper has been fastened to a pallet for safe transport.

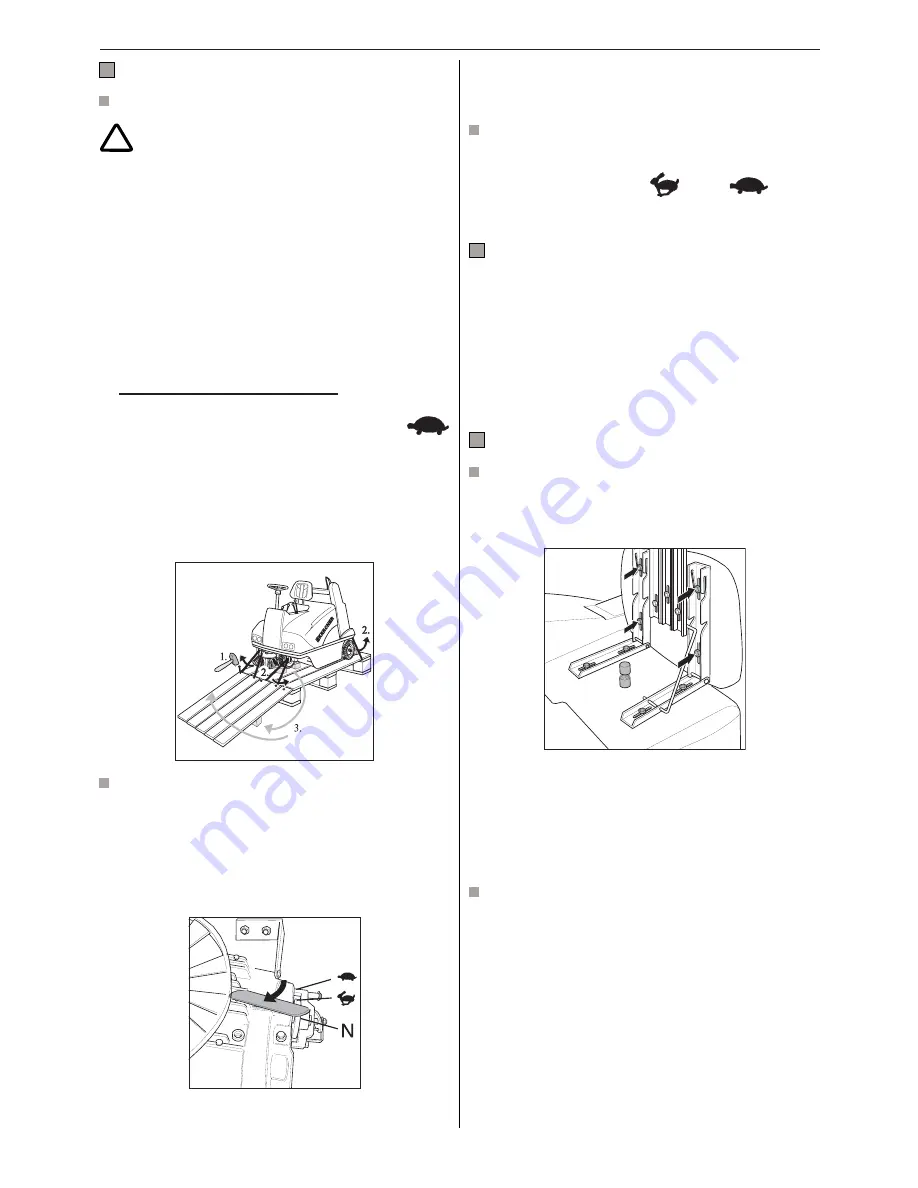

Proceed as follows for unpacking it:

1. Remove wooden boards from the pallet and nail them to

the abutments of the pallet (front end of the sweeper)

2. Remove strap attachments at the abutment points

3. Knock away the wooden blocks for locking the wheels

and use them for supporting the wooden boards on right

and left

4. Push the sweeper off the pallet over the ramp that has

been created

In sweepers with installed battery (1.091-111) it is

possible to drive down the ramp. To do this, open motor

cover and fold it back. Put gear lever into position

(slow), and close the cover again. Insert battery plug

connection (at drivers seat). Key switch to Position 1

and drive down carefully - see in addition chapter Driving

trials and Stopping the sweeper and switching off.

5. The side brush is tied to the frame for transportation

purposes. Undo the string.

Pushing the sweeper by hand

If you wish to move the sweeper without using its own drive:

Open the engine cover.

Fold the cover towards the rear; it will be held in place by

the gas-filled spring.

Put gear lever in direction of motion on to the

symbol

N

Release the handbrake.

Push the sweeper to the required destination.

After sweeper has been moved by hand:

Apply the handbrake.

Put gear lever into position

(fast) or

slow, as

otherwise the sweeper cannot be driven.

PRIOR TO EVERY START-UP

Check the hydraulic-fluid level, fill up if necessary (see

chapter Maintenance)

Check main brush roller for strapping or cord that may

have wrapped round it. If so, remove it.

Examine the dust filters, if there is heavy dust accumu-

lation shake them out

Empty waste hopper.

STARTING THE SWEEPER

Adjusting the drivers seat

The drivers seat can be adjusted to suit persons of various

heights by changing the seat position.

Unhook the rods for the seat tilting device.

Undo the 4 attachment screws

Move the seat to the desired position.

Tighten the screws and hook the rods back into the tilting

device.

Initial driving trials

Carry out initial driving trials in an area where there is plenty

of free space until you are familiar with the individual

operating controls and their functions.

All indications of direction (right/left, front/rear) are given in

relation to the direction of travel as seen from the drivers

seat.

Sit on the drivers seat.

The sweeper cannot be started until the driver has sat

down (seat contact switch). As soon as driver gets up

from the seat, the safety shut-down comes into force and

the drive control, blower fan and main brush roller drive

are disconnected.