17

English

Make sure that

the LH side brush (if fitted) is still in the raised position,

the RH side brush is still in the raised position,

the main brush is still in the raised position.

Put the starting key into Position 1. The sweeper is

ready to operate.

!

Important information

The drive mechanism is equipped with an electronic

overload fuse. Overload is indicated by a pilot lamp. In

the event engage the parking brake and release the drive

pedals(approx. 10 min.) until the drive components have

cooled down.

For safety reasons the drive mechanism remains inac-

tive if a drive pedal is engaged before the keyswitch is

turned on.

Working with the sweeper

Lower the main brush

and, if required, the side

brush as well

.

Main brush roller and side brush switch themselves on

automatically.

Switch the blower fan on in order to sweep without clouds

of dust forming.

Release the parking brake

by moving the lever

forwards

Slowly depress the drive pedal, the speed can be

selected smoothly according to the setting.

Depress left pedal, machine moves backwards.

Depress right pedal, machine moves forwards.

Braking

Release the drive pedal and the sweeper will brake

automatically.

Note

: The braking effect can be increased by careful

operation of the drive pedal for the opposite direction

and/or by using the parking brake.

Going up slopes

The sweeper can be driven in the fast gear (position

)

for slopes up to a gradient of 15 %.

For slopes of gradients between 15 % and 18 %, the

sweeper must be operated in low gear (position

).

Stopping the sweeper and switching off

Release the drive pedal. The sweeper brakes automati-

cally and comes to a halt.

Apply the parking brake

.

Make sure the main roller and side brush are raised so

that the bristles are not damaged. (Main brush roller,

side brush and blower fan switch off automatically).

Turn the ignition key to Position 0 and then remove it.

Clean the sweeper inside and outside as required.

Recommendation

: Clean interior with compressed air.

Wipe over the exterior with a damp cloth but do not use

an aggressive cleaning agent.

Park sweeper in a protected place and stop it from rolling

away.

Pull out battery plug connection.

If the sweeper is shut down for a relatively long period,

charge the battery at approx. two-monthly intervals, see

in addition chapter Maintenance.

Cleaning the filter

Manual cleaning

While the sweeper is operating, the filter should be cleaned

approx. every 1530 minutes (depending on amount of

dust).

Switch off the blower fan. The electric filter cleaner is

operated automatically for approx. 10 seconds.

Switch on the blower fan again.

Emptying the waste hopper

!

Important information

Injury hazard!

No person or animal should be allowed to remain in the area

traversed by the hopper while it is being emptied.

Danger of being crushed!

Do not reach into the shafts and linkage of the emptying

mechanism.

Do not stand under the raised hopper.

Risk of sweeper toppling over!

If the sweeper is standing on a slope with a gradient of more

than 5 %, it could topple over while the hopper is being

emptied. The hopper should therefore only be emptied when

the gradient at the location where the sweeper is standing

is less than 5 % for the direction in which it is facing.

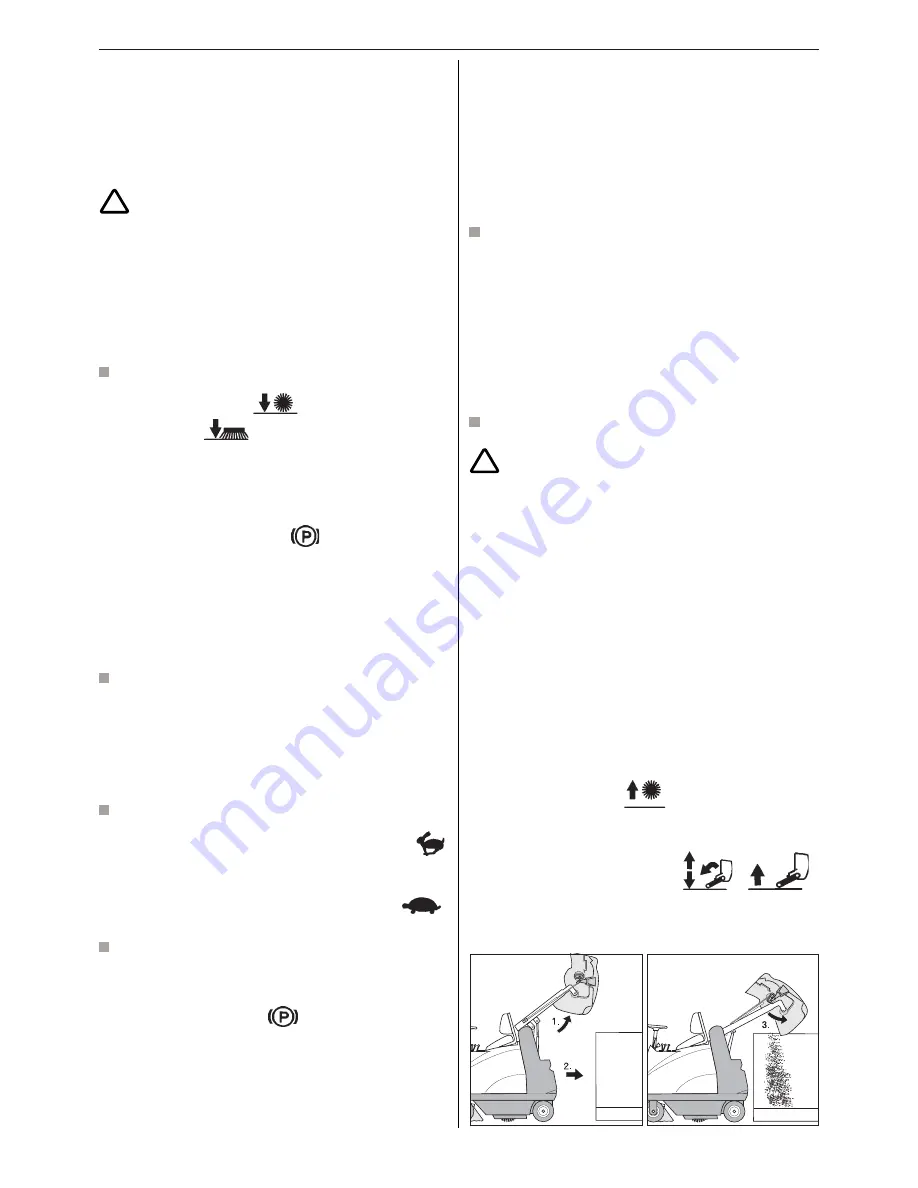

Stop the sweeper.

Raise the main brush

.

Note

: Following steps can only be performed with the

sweeper set to two-handed operation.

Raise the waste hopper, 1 + 2.

+

When the hopper has reached the required height drive

backwards towards the discharge container.