English

-

1

Please read and comply with

these original instructions prior

to the initial operation of your appliance and

store them for later use or subsequent own-

ers.

The packaging material can be recy-

cled. Please do not place the packag-

ing into the ordinary refuse for disposal, but

arrange for the proper recycling.

Old appliances contain valuable

materials that can be recycled.

Please arrange for the proper recy-

cling of old appliances. Please dispose

your old appliances using appropriate col-

lection systems.

–

Please do not release engine oil, fuel

oil, diesel and petrol into the environ-

ment Protect the ground and dispose of

used oil in an environmentally-clean

manner.

–

When removing workpieces, avoid get-

ting the floor dirty. If necessary, use a

pan or mats.

–

Please select the installation site so that

no liquid can leak into the soil or sewer

in case of leaks. If necessary, place the

machine into the pan.

–

Dispose of the detergent solution in an

environmentally friendly manner and

according to the local provisions.

Notes about the ingredients (REACH)

You will find current information about the

ingredients at:

http://www.karcher.de/de/unternehmen/

umweltschutz/REACH.htm

The machine has been designed for auto-

matic cleaning of parts with watery solution

in commercial and industrial applications.

–

The machine can only be operated us-

ing a watery detergent liquid.

–

Do not fill in solvents, inflammable or

explosive liquids.

–

Only liquid detergents listed in the

Kärcher catalog, detergents for clean-

ing parts, may be used.

–

The machine is only to be installed in

enclosed rooms.

The work station is located on the front of

the machine. This is the side that the con-

trol panel is installed on.

The liquid detergent in the detergent con-

tainer is heated by the heating element at

the set temperature and is transported via

the pump to the 2 nozzle pipes. The parts

to be cleaned are placed on an electrically

driven rotating table and are rotated around

the nozzle pipe frame. This ensures proper

cleaning from all sides.

After the cleaning time has expired or if a

manual reset is done, then the pump and

the electrical rotating drive get switched off

automatically. The cleaned parts can now

be taken off.

You can use a skimmer (upgrade kit, op-

tion) to separate the oil from the detergent

liquid that come in contact with the deter-

gent fluid during the cleaning process. To

ensure optimal functioning, the same can

only be activated between the cleaning

processes.

–

Please read the operating instructions

for your machine before using it, and

pay particular attention to the following

safety instructions.

–

In addition to the information contained

in the operating instructions, all statuto-

ry safety and accident prevention regu-

lations must be observed.

Danger

Immediate danger that can cause severe

injury or even death.

몇

Warning

Possible hazardous situation that could

lead to severe injury or even death.

Caution

Possible hazardous situation that could

lead to mild injury to persons or damage to

property.

–

The voltage indicated on the type plate

must correspond to the voltage of the

electrical source.

–

Safety class I - Appliances may only be

connected to sockets with proper earthing.

–

It is recommended that you connect this

device to a socket that has a 30 mA pro-

tection switch against wrong currents.

–

Please use the mains cable prescribed

by the manufacturer; the same is also

applicable when you replace the ca-

bles. For type details see circuit plan.

–

The appliance may only be connected

to an electrical supply which has been

installed by an electrician in accord-

ance with IEC 60364.

–

Operating procedures create short term

power sinkings.

During unfavorable net conditions other

devices might be disturbed.

With a net impedance lower then 0,15 Ohm

no disturbances are to be expected.

–

Never touch the mains plug with wet

hands.

–

Make sure that the power cord or exten-

sion cables are not damaged by run-

ning over, pinching, dragging or similar.

Protect the cable from heat, oil, and

sharp edges.

–

The power cord must be checked regularly

for damages, such as cracks or aging. If

damage is found, the cable must be re-

placed before further use.

–

If couplings of the power cord or extension

cable are replace the splash protection and

the mechanical tightness must be ensured.

–

The extension cable must have the cross-

section listed in the circuit plan and be pro-

tected against spraying water. The connec-

tion must not lie in water.

–

If couplings of the power cord or exten-

sion cable are replace the splash pro-

tection and the mechanical tightness

must be ensured.

Contents

Environmental protection . .

EN . . 1

Proper use . . . . . . . . . . . . .

EN . . 1

Function . . . . . . . . . . . . . . .

EN . . 1

Safety instructions . . . . . . .

EN . . 1

Safety Devices . . . . . . . . . .

EN . . 2

Device elements . . . . . . . . .

EN . . 3

Start up . . . . . . . . . . . . . . . .

EN . . 4

Operation . . . . . . . . . . . . . .

EN . . 4

Shutting down . . . . . . . . . . .

EN . . 5

Transport . . . . . . . . . . . . . .

EN . . 5

Maintenance and care . . . .

EN . . 6

Troubleshooting . . . . . . . . .

EN . . 7

Warranty . . . . . . . . . . . . . . .

EN . . 8

Spare parts . . . . . . . . . . . . .

EN . . 8

Technical specifications . . .

EN . . 8

CE declaration . . . . . . . . . .

EN . . 8

Environmental protection

Proper use

Please do not let mineral oil contaminated

waste water reach soil, water or the sew-

age system.

Function

Safety instructions

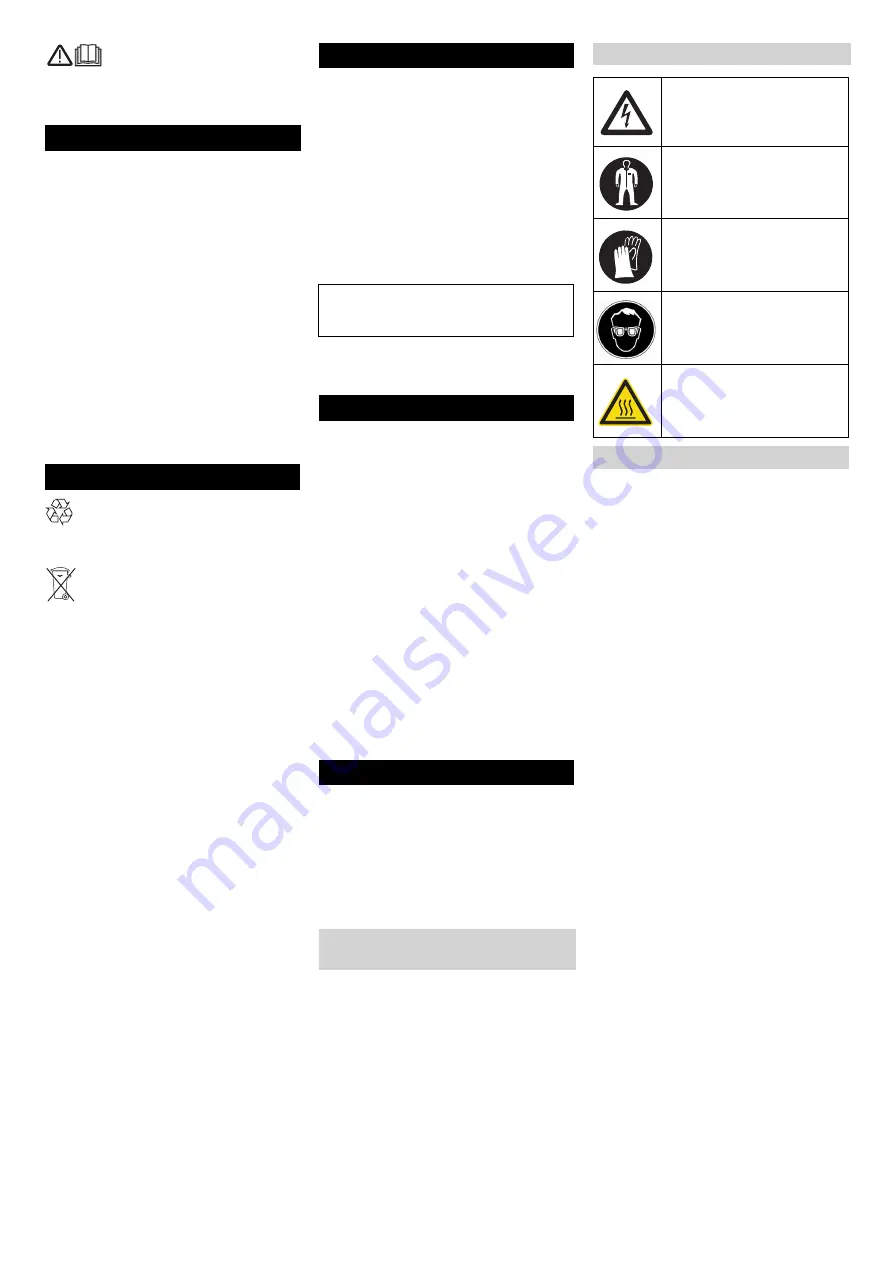

Symbols in the operating

instructions

Symbols on the machine

Risk of electric shock!

Only electricians or authorised

technicians are permitted to

work on parts of the plant.

The operator must wear prop-

er safety gear to be protected

against the water sprays.

Wear suitable protective

gloves during work.

Risk of injury on account of

spraying detergent liquid.

Wear safety goggles.

Risk of burns on account of hot

surfaces!

Power connection

11

EN

Summary of Contents for PC 60T

Page 2: ...2...

Page 92: ...2 0 15 Ohm 3 92 EL...

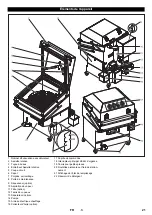

Page 93: ...3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Not Aus 19 20 21 22 93 EL...

Page 94: ...4 1 2 3 AUTO OFF 1 ON 4 5 6 94 C 7 AUTO OFF 1 ON 8 80 C 130 kg 30 3 1 2 3 OFF 94 EL...

Page 95: ...5 Am besten vor Arbeitsbeginn durchf hren 1 A 5 B C1 1 C2 2 C D E F G 1 2 H I 1 95 EL...

Page 96: ...6 1 K rcher 40 200 1000 96 EL...

Page 97: ...7 0 97 EL...

Page 108: ...2 0 15 BGV A3 108 RU...

Page 109: ...3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 109 RU...

Page 110: ...4 1 2 3 OFF 1 ON 1 4 5 6 94 C 7 OFF 1 ON 1 8 80 C 130 30 1 2 3 OFF 110 RU...

Page 111: ...5 Am besten vor Arbeitsbeginn durchf hren 1 A 5 B C1 1 C2 2 C D E F G 1 2 H I 1 111 RU...

Page 112: ...6 1 Karcher 40 200 1000 112 RU...

Page 113: ...7 0 113 RU...

Page 180: ...2 30 mA IEC 60364 1 0 15 Ohm BGV A3 180 BG...

Page 181: ...3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 181 BG...

Page 182: ...4 1 2 3 AUTO OFF 1 ON 4 5 6 94 C 7 AUTO OFF 1 ON 8 80 C 130 30 3 1 2 3 OFF 182 BG...

Page 183: ...5 Am besten vor Arbeitsbeginn durchf hren A 5 B C1 1 C2 2 C OK D E F G 1 2 H I 1 T o 183 BG...

Page 184: ...6 1 K rcher 40 200 1000 184 BG...

Page 185: ...7 0 185 BG...

Page 212: ...2 0 15 BGV A3 212 UK...

Page 213: ...3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 213 UK...

Page 214: ...4 1 2 3 OFF 1 ON 1 4 5 6 94 C 7 OFF 1 ON 1 8 80 C 115 30 3 1 2 3 OFF 214 UK...

Page 215: ...5 Am besten vor Arbeitsbeginn durchf hren A 5 B C1 1 C2 2 C OK D E F G 1 2 H I 1 215 UK...

Page 216: ...6 1 K rcher 40 200 1000 216 UK...

Page 217: ...7 0 217 UK...

Page 219: ......