English

5.906-507.0 Rev. 00 (08/10)

11

Î

Remove the motor as described in Chapter 5.2.2.

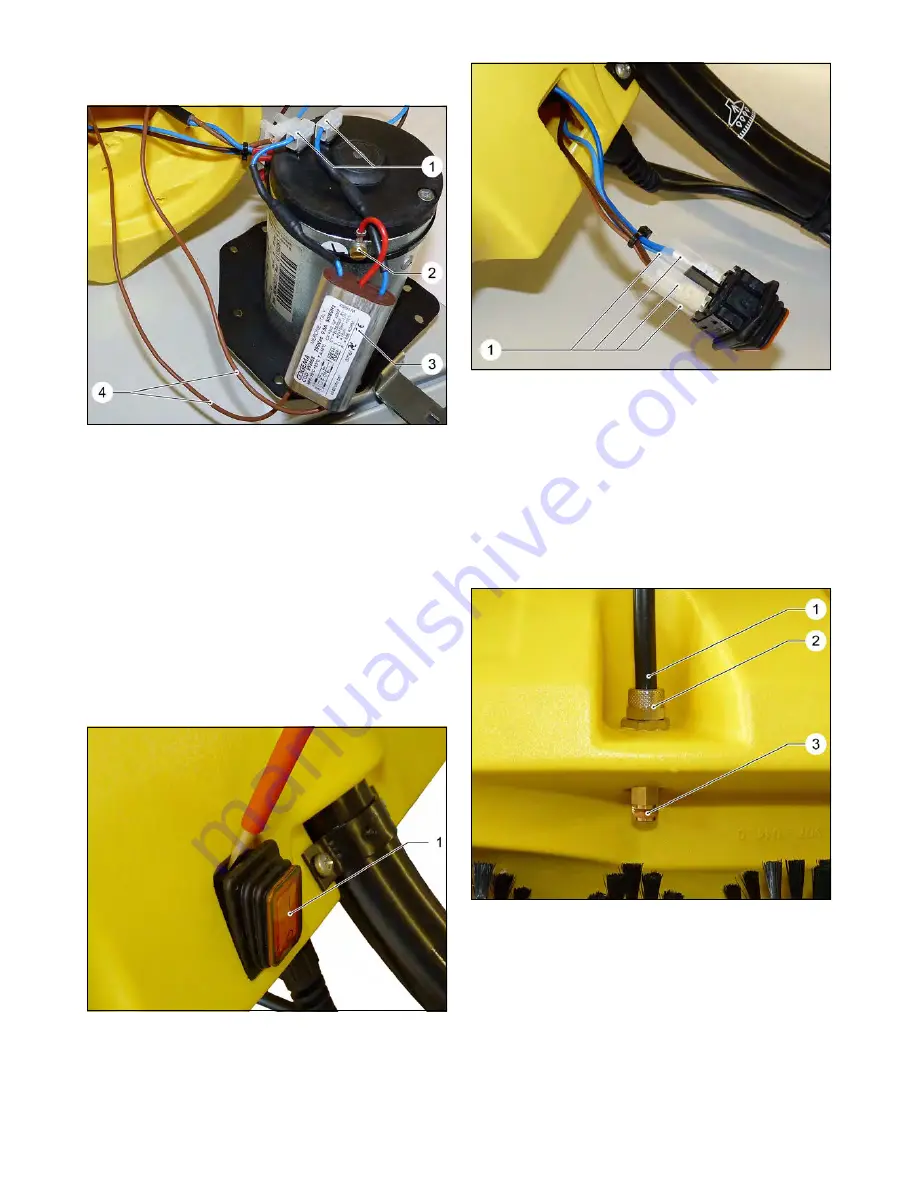

1 Motor connection plug

2 Cable connector screw, noise filter

3 Anti-interference filter

4 Connecting cable, noise filter

Î

Pull the motor connection plug from the motor.

Î

Unscrew the cable connector screw from the noise

filter on the motor.

Î

Remove the connecting cable from the appliance

switch/safety switch.

Î

Install the new noise filter in reverse order.

Î

Install the motor as described in Chapter 5.2.2.

The removal of the toothed drive wheel is described

in the Chapter 5.5.2.

1 Power switch

Î

Push out the appliance switch from the casing us-

ing a screwdriver.

1 Connecting cable (4x), appliance switch

Î

Remove the appliance switch from the casing.

Note

In order to avoid failures, remember the plug connec-

tions of the different connecting cables on the appli-

ance switch.

Î

Remove all four connecting cable from the appli-

ance switch.

Î

Replace the appliance switch and install it in re-

verse order.

1 Spray hose

2 Lock nut

3 Spray nozzle

Î

Place the PW 30/1 on its back.

Î

Unscrew the knurled nut.

Î

Pull the spray hose from the spray nozzle.

5.2.3 Replace the interference filter

5.2.4 Replace toothed drive wheel

5.2.5 Replace appliance switch

5.2.6 Replace the spray hose