English

55

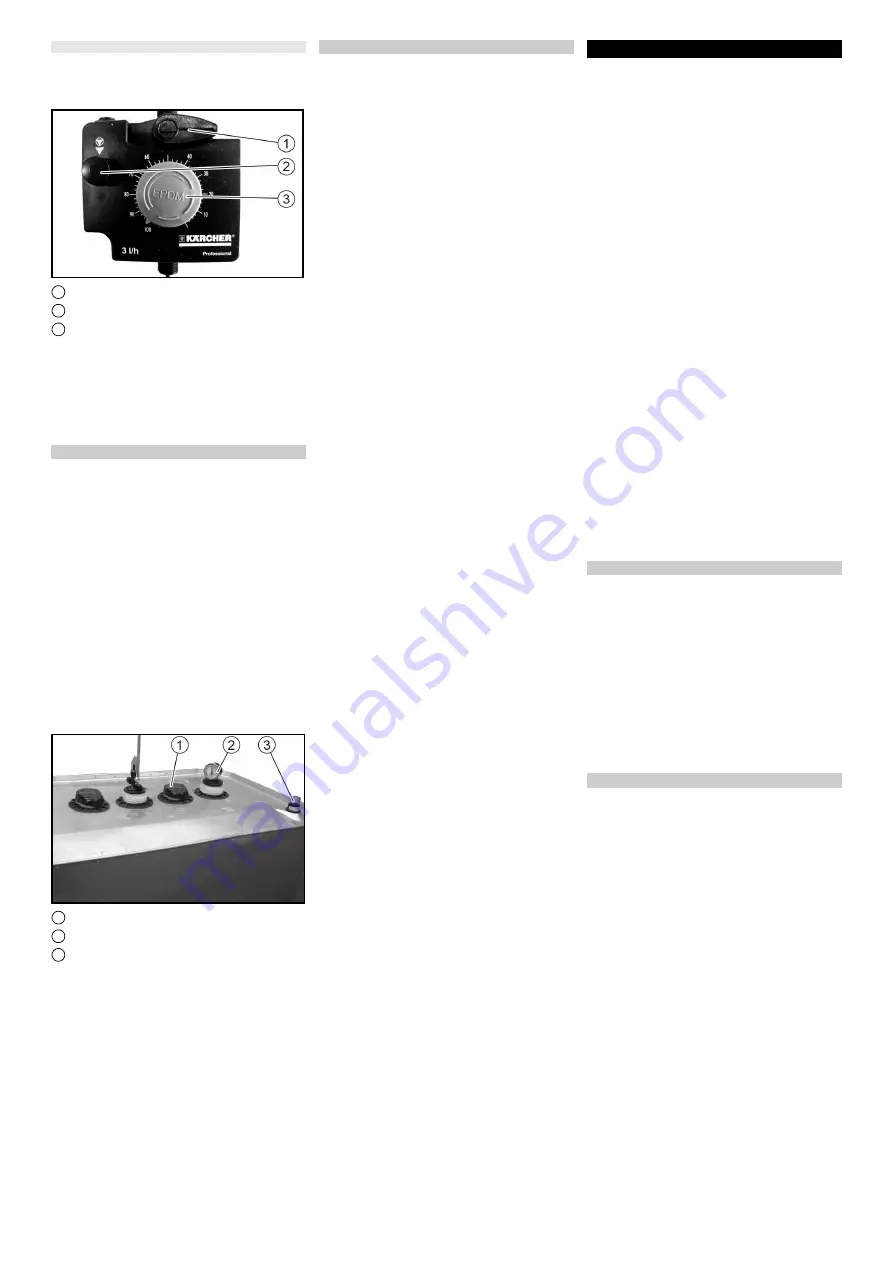

Vent the dosing pump

The system compressed air supply must be in opera-

tion.

1. Turn the venting lever anticlockwise as far as it will

go.

1

Venting lever

2

Venting button

3

Dosing amount adjustment knob

2. Set the dosing amount to 100%.

3. Press the ventilation button repeatedly until the de-

tergent comes out of the venting line on the under-

side of the dosing pump without bubbles.

4. Reset the dosing quantity to the desired value, see

"Settings / Setting the dosing pumps / Standard set-

ting".

5. Turn the venting lever clockwise as far as it will go.

Refuelling

DANGER

Risk of fire

Fuel can ignite.

Observe the locally applicable regulations on the han-

dling of fuel.

Do not use unsuitable fuels as they can be dangerous.

ATTENTION

Risk of damage

If the fuel tank is empty, the fuel pump runs dry and can

get damaged.

Check the fuel tank filling level regularly.

Burner faults

Incorrect fuel can lead to burner faults and poor com-

bustion.

Only use the fuel specified in the "Technical data" sec-

tion.

Use heating oil with a winter operation additives (flow

improvers) if there is a risk of frost.

Fuel overflow

Fuel expands when warmed and can overflow.

Do not fill the fuel container to the brim.

1. Unscrew the cap of the filling nozzle.

1

Filling nozzle

2

Filling level display

3

Inspection opening

2. Fill with fuel until the filling level display shows full.

Note

Make sure that no fuel overflows and gets into the in-

spection opening. During a later inspection, this fuel

could be mistaken for leakage.

3. Close the filling nozzle.

Replenishing softening salt

ATTENTION

Malfunctions possible

Unsuitable salt can interfere with the function of the

base exchanger.

Only use the softening salt in tablet form specified in the

"Accessories" chapter.

1. Remove the lid of the salt tank.

2. Fill the salt tank to the top with softening salt.

3. Fit the lid of the salt tank.

Note

An empty salt tank causes malfunction. Fill up the salt

tank at the latest when water is visible in the salt tank af-

ter removing the lid.

Salt consumption does not increase when the salt tank

is completely full.

In a correctly working system, the salt consumption is

constant in relation to the water consumption.

We recommend documenting the salt and water con-

sumption in an operating log.

Frost protection

The frost protection device consists of:

●

Recirculation fan

●

Hot air blower

●

Frost protection circuit or frost protection with water

loss

●

Washing station heater

●

Emergency frost protection

●

Heating cartridge in the oil tank

몇

WARNING

Danger of accident

If there is black ice, there is a risk of accidents for the us-

ers of the washing bay.

Lock out washing stations when black ice forms to pre-

vent black ice accidents.

Note

The following features are guaranteed:

●

Unrestricted washing with the high-pressure spray

lance down to -15°C. For systems with 4 washing

stations, it is recommended to lock out one washing

station below -10°C (for systems with 4 high-pres-

sure modules type 908 already at warmer tempera-

tures).

●

Restricted washing with the washing brush at tem-

peratures below 0°C. During restricted washing, all

washing brushes must be checked regularly for ic-

ing. Foam washing with an iced washing brush can

damage the vehicle. If the washing brush is iced up,

the following measures must be taken:

1-tool version:

Replace the combination spray

lance with a high-pressure spray lance.

2-tool version (option):

Refrain from foam washing

(e.g. by giving instructions to the user).

●

At temperatures below –15°C, washing makes no

sense because an ice coating forms on the vehicle.

This ice coating can even impair the function of im-

portant vehicle components. Therefore, prevent use

of the system below -15°C by locking out the wash-

ing stations.

●

The system is frost-proof down to -20°C. Below -

20°C the device must be shut down as described in

the section "Shutting down in case of frost".

Prerequisites for frost protection

●

The main switch must be in position 1.

●

The doors of the system must be closed.

●

An uninterruptible power supply, water supply and

fuel supply must be ensured.

●

The water supply must be protected against frost.

●

The fuel supply must be protected against frost (e.g.

heating cartridge in the tank, trace heating).

●

Set up and install as described in the chapter "Set-

ting up the system".

●

The hot air blowers are set correctly.

●

All maintenance measures described in the "Mainte-

nance and care" chapter have been performed.

●

All cleaning tools are returned to the storage com-

partments.

●

The trigger guns with frost protection bore belonging

to the system are installed.

Washing station heater

Note

A prerequisite for the correct functioning of the washing

station heater is that the washing station is designed by

the customer in accordance with KÄRCHER's recom-

mendations.

The washing station area that can be heated is limited

by the corresponding heating capacity of the device. If

the heated area exceeds this value, frost protection is

not ensured. The number of washing stations that can

be heated is given in the chapter "Technical data / data

depending on hot water generation".

Snow coating and larger quantities of ice chunks that

have fallen off the vehicles require a very high heating

capacity. It is necessary to remove these deposits.

Summary of Contents for SB MB

Page 39: ...Deutsch 39 Ma blatt Variante CAB SB MB Standard SB MB Comfort...

Page 40: ...40 Deutsch Ma blatt Variante SKID SB MB Standard SB MB Comfort...

Page 41: ...Deutsch 41 Ma blatt Variante SKID mit Anbausatz WSO...

Page 80: ...80 English Dimension sheet variant CAB SB MB standard SB MB comfort...

Page 81: ...English 81 Dimension sheet variant SKID SB MB standard SB MB comfort...

Page 82: ...82 English Dimension sheet variant SKID with attachment kit WSO...

Page 123: ...Fran ais 123 Fiche de dimensions variante CAB SB MB Standard SB MB Comfort...

Page 124: ...124 Fran ais Fiche de dimensions variante SKID SB MB Standard SB MB Comfort...

Page 125: ...Fran ais 125 Fiche de dimensions variante SKID avec kit de montage WSO...

Page 165: ...Italiano 165 Scheda dimensionale variante CAB SB MB Standard SB MB Comfort...

Page 166: ...166 Italiano Scheda dimensionale variante SKID SB MB Standard SB MB Comfort...

Page 167: ...Italiano 167 Scheda dimensionale variante SKID con kit di fissaggio WSO...

Page 206: ...206 Nederlands Maatblad variant CAB SB MB standaard SB MB comfort...

Page 207: ...Nederlands 207 Maatblad variant SKID SB MB standaard SB MB comfort...

Page 208: ...208 Nederlands Maatblad variant SKID met aanbouwset WSO...

Page 248: ...248 Espa ol Hoja de medidas variante CAB SB MB Standard SB MB Comfort...

Page 249: ...Espa ol 249 Hoja de medidas variante SKID SB MB Standard SB MB Comfort...

Page 250: ...250 Espa ol Hoja de medidas variante SKID con juego de montaje WSO...

Page 289: ...Svenska 289 M ttblad variant CAB SB MB Standard SB MB Comfort...

Page 290: ...290 Svenska M ttblad variant SKID SB MB Standard SB MB Comfort...

Page 291: ...Svenska 291 M ttblad variant SKID med p byggnadssats WSO...

Page 330: ...330 Suomi Mittalehti versio CAB SB MB Standard SB MB Comfort...

Page 331: ...Suomi 331 Mittalehti versio SKID SB MB Standard SB MB Comfort...

Page 332: ...332 Suomi Mittalehti versio SKID liit nt sarjalla WSO...

Page 337: ...337 2 3 4 2 A 3 3 Powerschaum STOP 1 SB MB Comfort 2 SB MB Comfort 3 SB MB Standard 4 5 6...

Page 353: ...353 1 2 2 3 4 5 6 1 7 8 9 10 11 12 13 2 3 4...

Page 354: ...354 1 2 2 3 4 5 6 1 7 8 9 10 11 3 2 3 4 1 2 3 4 5 6 7 8 9 10 11...

Page 355: ...355 SB MB Standard SB MB Comfort RO RO RO RO RO 4 60 C 0 OFF 1 2 K RCHER K RCHER...

Page 358: ...358 SB MB 6 419 070 0 25 C 0 07 0 15 MPa 0 7 1 5 bar 0 5 l min 0 0 5 l min 2 WZ 30 mm 5 C ABS...

Page 360: ...360 1000 WSO Power Power WSO RO 5...

Page 364: ...364 1 2 3 10 C F0144 S5...

Page 365: ...365 1...

Page 366: ...366 1 1 2 3 0 6 mm 4 1 3 mm 5 6 7 8 0 25 MPa 2 5 bar WAT S 202 WAT S 202 2...

Page 367: ...367 0 3 MPa 3 bar RO RO RO RO RO...

Page 373: ...373 CAB SB MB Standard SB MB Comfort...

Page 374: ...374 SKID SB MB Standard SB MB Comfort...

Page 375: ...375 SKID WSO...

Page 376: ...376...

Page 381: ...381 1 2 3 4 5 6 7 8 2 9 1 10 11 12 13 14 1 0 4 0 5 4 5 1 2 3 4 1 DP 1 2 DP 2 3 DP 3 4 DP 4 1 0...

Page 384: ...384 1 2 1 2 3 4 5 6 7 8 9 10 1 1 2 1 2 3 4 5 6 7 8 9 10 Home 1 2 3 4 5 6 Home 7 1 8 2 2 1 2...

Page 391: ...391 1 1 1 1 1 1 2 3 2 3 4 1 0 OFF 1 1 ON 2 3 1 2 1 2 3 4 5 6 7 8 9...

Page 394: ...394 1 2 3 4 5 6 7 8 9 10 11 12 13 1 2 3 4 5 6 7 8 9 10 1 2 48 3 4 24 48 5 6 7 8 1 80 100 2 3...

Page 395: ...395 B C 1 2 3 4 5 6 7 8 9 10 1 11 1 12 13 14 15 16 17 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15...

Page 397: ...397 1 2 2 3 4 5 6 1 7 8 9 10 11 12 13 2 3 4...

Page 398: ...398 1 2 2 3 4 5 6 1 7 8 9 10 11 3 2 3 4 1 2 3 4 5 6 7 8 9 10 11...

Page 399: ...399 SB MB Standard SB MB Comfort 4 60 0 OFF 1 2 K RCHER K RCHER...

Page 401: ...401 1 2 3 WSO 1 6 1 1 6 2 1 2 1 2 3 1 2 3 4 5 6 1 IP 2 3 4 1 1 2 3 4 1 2 3 4...

Page 402: ...402 SB MB 6 419 070 0 25 C 0 07 0 15 0 7 1 5 0 5 0 0 5 2 30 5 C...

Page 404: ...404 200 9 10 90 100 0 5 5 25 6 288 055 0 6 288 072 6 288 116 1000 WSO WSO...

Page 408: ...408 10 C F0144...

Page 409: ...409 1 2 3 S5 1...

Page 410: ...410 1 1 3 0 6 4 1 3 5 6 7 8 0 25 2 5 WAT S 202 WAT S 202 2...

Page 411: ...411 0 3 3...

Page 417: ...417 CAB SB MB Standard SB MB Comfort...

Page 418: ...418 SKID SB MB Standard SB MB Comfort...

Page 419: ...419 SKID WSO...

Page 420: ...420...

Page 422: ......

Page 423: ......