4

CONTENTS

WTC 600 LP / MP

Service Handbook 08.2004

Contents

3.2.5.2 Perform flocking test ............................................................................................... 26

3.2.5.3 Evaluate flocking test ............................................................................................. 26

3.3

Connecting the Equipment ................................................................................ 27

3.3.1

Connections, Valves and Indicators ....................................................................... 27

3.3.1.1 Pressure-increase Module .................................................................................... 28

3.3.1.2 RO Module with Preliminary Filters ....................................................................... 28

3.3.2

Electrical Connections ........................................................................................... 29

3.3.2.1 Pressure-increase Pump ...................................................................................... 29

3.3.2.2 Preliminary Filter ................................................................................................... 29

3.3.2.3 Metering Station .................................................................................................... 29

3.3.2.4 Float Switch ........................................................................................................... 31

3.3.2.5 Reverse Osmosis System .................................................................................... 31

3.4

Starting Operation ............................................................................................... 31

3.4.1

Metering Station ..................................................................................................... 31

3.4.2

Media filter and activated carbon filter .................................................................... 32

3.4.2.1 Initial Filling ............................................................................................................ 32

3.4.2.2 Starting Operation ................................................................................................. 32

3.4.2.3 Backwashing / Regeneration ................................................................................ 32

3.4.2.4 Programming ......................................................................................................... 33

3.4.3

Starting Operation of the RO System .................................................................... 35

3.4.3.1 Operating Levels and Passwords ......................................................................... 35

3.4.3.2 Menu Selection ...................................................................................................... 35

3.4.3.3 Selection of an Option ........................................................................................... 35

3.4.3.4 Selecting Several Arguments at the Same ............................................................ 36

3.4.3.5 Adjusting Operating Parameters and Balancing Values ......................................... 36

3.4.3.6 Acknowledging Data Inputs .................................................................................. 36

3.4.3.7 Operational Interruptions ....................................................................................... 36

3.4.3.8 Initial startup ........................................................................................................... 38

3.4.4

Normal Operation ................................................................................................... 40

3.4.4.1 Operating Messages for Normal Operation .......................................................... 41

3.4.5

Putting Out of Operation ......................................................................................... 42

3.4.6

Disinfection ............................................................................................................. 43

4

Maintenance .............................................................................. 44 - 62

4.1

Fine Filter ............................................................................................................. 44

4.2

Metering Station WTC 600 CD ............................................................................ 44

4.3

Reverse Osmosis Module (RO Module) ............................................................ 45

4.3.1

RO Filter Replacement ........................................................................................... 45

4.4

Cleaning in Case of Malfunction ........................................................................ 46

4.4.1

Design of the Flushing and Disinfection Equipment ............................................... 47

4.4.2

Disinfection ............................................................................................................. 49

4.4.3

Acidic and Alkaline Cleaning .................................................................................. 50

4.4.3.1 Cleaning Solution for Acidic Cleaning ................................................................... 51

Summary of Contents for WATERCLEAN 600 CD

Page 1: ...Service Handbook 5 905 521 08 2004 Waterclean 600 CD LP MP PI 1 024...

Page 6: ...WTC 600 LP MP 6 Service Handbook 08 2004...

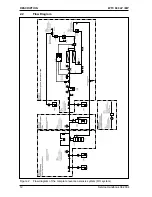

Page 64: ...64 APPENDIX WTC 600 LP MP Service Handbook 08 2004 RO control program structure Figure21...

Page 65: ...65 WTC 600 LP MP APPENDIX Service Handbook 08 2004...