WTC 600 LP / MP

9

Maintenance and Care

Version 06/05

Notice: The amount of concentrate will in-

crease. This is correct.

Observe the maximum pressure of 21 bar

(MP) or 14 bar (LP) at the manometer (11)!

• Repeat the adjustment steps, if required. The

original drinking water amount may possibly

not quite be reached.

(3)

The difference between pump and

concentrate pressure has increased

by more than _____ bar

• Read the values at the manometer for the

pump pressure (11) and for the concentrate

pressure (12), and determine the differential

pressure.

• Compare the differential pressure with the

value taken when starting operation (see oper-

ational start-up record).

3.2.6

Mixing the Chemicals

(1)

Metering Table

If the differential pressure has in-

creased by more than _____ bar, then

the RO filter membrane is clogged.

Readjustment is no longer possible.

Stop the drinking water production and

notify the Kärcher Service.

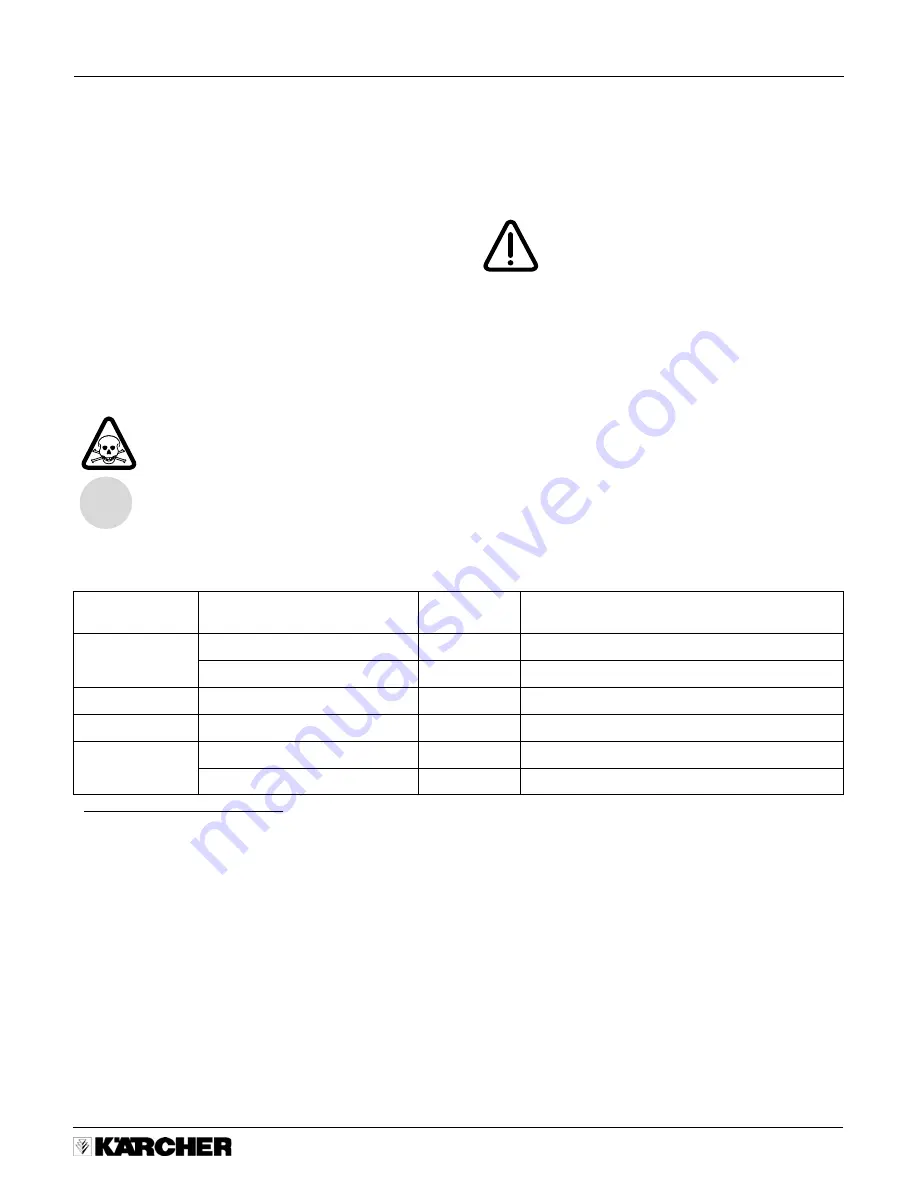

When working with chemicals, always wear protective clothing.

i

Values for the metering of the various chemicals result from the untreated water analysis and

the system capacity.

Upon starting operation, the Kärcher service technician enters the required metering amounts

for your equipment into the following metering table.

Metering

Container

Chemical

Item No.

Metered Amount of the Chemical

[ml]

per

10 l Metering Solution

Pre-

chlorination

RM 852 sterilization agent

*

6.291-772.0

Chlorinated lime

*

6.291-505.0

Pre-flocculation Ferrifloc

6.294-703.0

Anti Scalant

RM 5000 hardness stabilizer 6.290-991.0

Post

chlorination

RM 852 sterilization agent

*

6.291-772.0

Chlorinated lime

*

6.291-505.0

* These chemicals can each be used alternatively