38

Maintenance

Do not use a pressure washer to clean around the

brush motors. Use tap pressure only.

N’utilisez pas de nettoyeur haute pression pour

nettoyer autour des moteurs des brosses. Utilisez

seulement la pression du robinet.

Remove Brush Deck

1. Lower brush deck.

2. Turn off machine

3. Disconnect motor harness connectors and remove

vacuum hose from top of deck.

4. Remove bumper bolts and bumper to access

linkage mount brackets.

5. Pull down and disconnect spring mount bracket

from deck lift arm. Keep spring attached to mount

bracket.

6. Remove four (4) bolts and associated hardware

that connect deck lift arm to linkage mount

brackets on drive assembly.

7. Remove two (2) bolts and associated hardware

that connect deck lift arm to lift linkage plate.

8. Pull out deck with attached deck lift arm.

9. Reverse to reassemble.

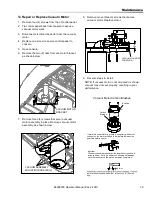

Replace Brush Deck Motor

1. Remove brush deck from machine.

2. Remove two (2) nuts to free rear mounting bracket

from deck.

3. Remove six (6) motor mount bracket face screws.

4. Remove rear mounting bracket.

5. Remove motor with attached coupler, leaving front

motor mounting bracket still attached to deck.

6. Remove coupler from old motor for reuse.

7. Inspect spider coupler for wear replace as needed.

Reverse process to reassemble with new motor.

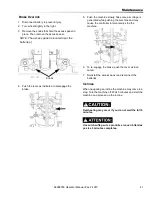

Brush Motor Carbon Brush Replacement

1. Scribe alignment mark on motor barrel to motor

cap. Remove two bolts.

2. Remove end cap from motor.

NOTE: Motors contain two wave washers in cap. Do

not lose these.

3. Release brush from spring tension. Remove screw

connecting brush wire lead to brush holder. Clean

brush holder to insure free movement.

4. Retract spring and install new brush. Install

connector screw and lead.

5. When all new brushes are installed. Place all in

retracted position, held into brush holder by spring

tension.

6. Carefully place end cap onto bearing on motor

shaft.

NOTE: Use care to assure wave washer alignment.

7. With end cap in partially installed position, release

all brushes to contact position with motor commu-

tator.

NOTE: Failure to insure all brushes are released will

result in motor failure.

8. Reset end cap and realign with scribe marks on

motor barrel. Reinstall the two attach bolts from

cap into base.Maintain alignment between motor

barrel base and cap.

FOR SAFETY:

before leaving or servicing machine,

stop on a level surface, turn off machine and discon-

nect powe

r.

Replacing Coupler Spider

1. Remove three (3) cover screws and drive housing

cover from end of brush deck.

2. Remove four (4) drive housing mounting screws

3. Slide out brush drive housing assembly with

attached coupler from end of brush deck extrusion.

4. Replace coupler spider.

5. Reverse to assemble.

NOTE: Align coupler jaws when sliding in brush drive

housing assembly.

86398780 Operator Manual iVac 24 ATV