84000JF & 3.1JF ASSEMBLY AND INSTALLATION INSTRUCTIONS

STEP ONE

Remove all contents from package and place on a

clean, flat surface. Inspect the shipment for any dam-

ages. If damages are found, immediately notify your

carrier and your Kasco Marine, Inc. representative.

Next, cross reference the parts included in the ship-

ment with the Parts Included sheet in this manual on

page 4 and 5. Make sure you have all the parts

needed. If any shortages are found, contact your

Kasco representative immediately.

STEP TWO

Arrange the three Float Sections (Part #B1) upright

(plug on bottom) so the overlap of one section aligns

with the next section and loosely push the three sec-

tions together to form a continuous ring.

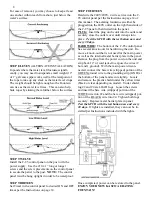

STEP THREE

Position one Top Float Bracket (Part #B2) so that the

bolt holes in the bracket align with the bolt holes in

the two adjoined float sections and insert two 9”

Coated Bolts (Part #B4) through the assembly. This

may require some minor repositioning of the float

sections as you push the bolt all the way through.

Do

not force the bolt through.

Repeat for the remaining

two joints.

STEP FOUR

Turn the assembly upside down and place the Bottom

Float Brackets (Part #B3) over the bolts, the ends of

which should now be extending through the assem-

bly. Loosely install the six 3/8” Lock Nuts (Part

#B5) on the ends of the bolts (do not tighten yet).

Connect the Top and Bottom Float Brackets using

three 1/4” x 3/4”

Bolts (Part #B7)

with three 1/4”

Lock Washers

(Part #B8) and

three 1/4” Nuts

(Part #B12) and

tighten using the

7/16” wrench and

socket.

STEP FIVE

Stand the assembly on its side and center the Top

Screen (Part #B10) inside the three Top Float Brack-

ets. Attach the screen by spanning each Top Screen

Clip (Part #B11) across the two innermost rings on

the screen and the

hole in the float

bracket. Insert the

3/4” Brass Screws

(Part #B14) and at-

tach with 1/4” Lock

Washers and 1/4”

Nuts to secure the

screen to the float

assembly.

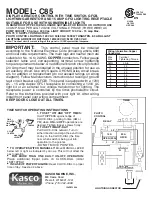

STEP SIX

Return the assembly to the upside down position and

place the motor assembly (Stainless Steel can side up,

black pump down) in the center of the float. Attach

the motor to the float using the Unit Mounting Brack-

ets (Part #B6). The notch in the center of the Unit

Mounting Brackets should be positioned over the top

ring of the cage and should be attached to the float

bracket using the two middle holes of the float

bracket. Tighten using the 1/4” x 3/4” Bolts with

1/4” Lock Washers using the 7/16” socket and

wrench. (See pictures on next page)

Note: If you

have trouble positioning the Unit Mounting Bracket

between the Cage and Fountain Housing, you can

use a screwdriver to gently pry open enough space.

6