10

ASSEMBLY

Drive shaft to engine (Fig. 1)

Loosen tube locking bolt (1) about ten turns so

that the bolt point will not obstruct drive shaft tube

to be inserted. When inserting drive shaft tube,

hold the tube locking bolt outward preventing

inside fitting from obstructing as well.

Insert the drive shaft into the clutch case of the

engine properly on the drive shaft tube meets the

clutch case.

Some models may come with the drive shaft

already installed.

NOTE

When it is hard to insert drive shaft up to the

marked position on the drive shaft tube, turn drive

shaft by the cutter mounting end clockwise or

counter-clockwise. Tighten tube locking bolt lining

up the hole in the shaft tube. Then tighten clamp

bolt securely (1).

Installation of handle

Remove the handle bracket (2) from the

assembly.

(Fig. 2)

Place the handles and attach the handle bracket

with four bolts lightly. Adjust to appropriate

position. Then attach it fi rmly with the bolts.

Attach the protection tube to the drive shaft or

handle using cord clamps (3).

(Fig. 3)

NOTE

If the protection tube is set apart from the handle

or pipe, it will be caught by something during

operation and it may cause serious injury. Do not

set the protection tube apart from the handle or

pipe.

Throttle wire / stop cord

Remove air cleaner cover.

(Fig. 4)

Connect stop cords.

(Fig. 5)

Insert the stay (4) under the nut (5) screwed onto

the outer end of the throttle wire (6) and connect

the end of the throttle wire (7) to the carburetor (8).

Then tighten the nut (5) to secure the throttle wire

to the stay (4).

(Fig. 6)

NOTE

Check that the carburetor throttle returns to the

idle position and also that it can be opened wide

by operating the throttle lever.

Cover throttle wire and stop cords together with

protective tube provided up to air cleaner cover.

(Fig. 7)

Some models may come with the drive shaft

already installed.

Installation of blade guard (Fig. 8)

The guard bracket already mounted to the drive

shaft tube. Install the blade guard on drive shaft

tube against angle transmission. Tighten the

guard bracket fi rmly so that the blade guard does

not swing or move down during operation.

WARNING

If an incorrect or faulty guard is fi tted, this may

cause serious

personal injury.

CAUTION

The blade guard must be in place during

operation. If the blade guard is not in place, there

is a possibility of serious injury.

Blade guards are equipped with sharp line limiter.

Be careful with handling it.

When using a trimmer head, attach the guard

extension to the blade guard.

(Fig. 9)

NOTE

○

When attaching the guard extension to the

blade guard, the sharp line limiter must be

removed from the blade guard.

○

To remove the guard extension, refer to the

drawings. Wear gloves as the extension has a

sharp line limiter, then push the two square tabs

on the guard one by one in order after removed

the screw.

(Fig. 10)

Installation of cutting attachment

WARNING

Install the cutting attachment properly and

securely as instructed in the handling instructions.

If not attached properly or securely, it may come

off and cause serious and/or fatal injury.

Installation of semi-auto cutting head

1. Function

Automatically feeds more nylon cutting line when

it is tapped at

low rpm (not greater than 4500 min-1).

Applicable nylon cord

Cord diameter: Φ2.5 mm

2. Precautions

○

The case must be securely attached to the

cover.

○

Check the cover, case and other components

for cracks or other damage.

○

Check the case and button for wear.

○

The cutting head must be securely mounted to

the unit’s gear case.

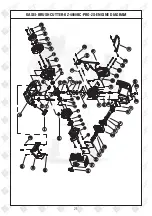

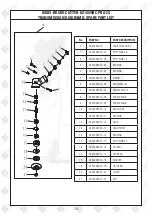

Summary of Contents for KZ-4000BC-PRO-2S

Page 3: ...1 2 3 8 7 5 6 4 3 2 1 6 5 4 9 8 7 1 0 1...

Page 4: ...9 1 0 1 1 1 2 1 3 1 4 1 5 1 6 1 6 3 1 2 1 1 1 5 1 4 1 7 1 6 1 2...

Page 5: ...3...

Page 6: ...2 9 3 0 3 1 2 3 1 3 0 3 5 3 4 3 3 3 7 3 6 3 3 8 4...

Page 23: ...21 KASEI BRUSH CUTTER KZ 4000BC PRO 2S ENGINE DIAGRAM...

Page 34: ...32 Small Maintenance Big Savings Small Maintenance Big Savings Small Maintenance Big Savings...

Page 35: ......