CUTTING WITH A NYLON HEAD

15

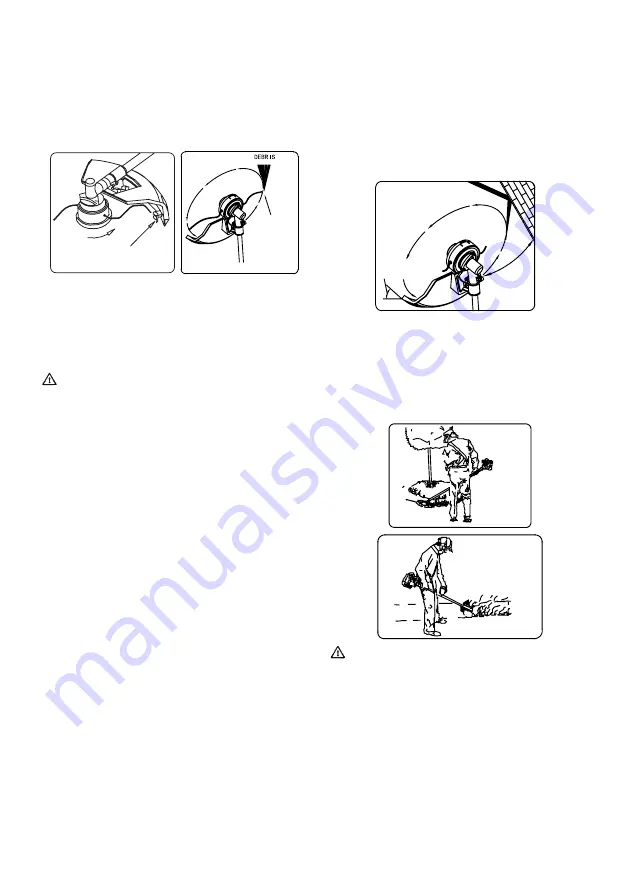

Line head rotates in a CLOCKWISE direction.The

CUT-OFF KNIFE will be on the right side of the

debris shield.

slowly until the grass is cut right up the barrier,but

do not jam(overfeed )the line into the barrier.If

trimming up to a wire mesh or chain linked fence

be careful to feed only up to wire. If you go to far

the line will snap off around the wire.

ON LEFT SIDE

CUT-OFF KNIFE

CUT ON

COUNTER CLOCK WISE ROTATION

THIS SIDE

WARNING

The proper debris shield must be in place on

the unit when nylon cutting line is used. The

cutting line can flap around if too much line is

exposed. Always use the plastic debri shield

with cut-off knife when using nylon cutting

heads.

Tilting the head to the wrong side will shoot the

debris TOWARDS you.If the line head is held

flat to the ground so that cutting occurs on the

whole line circle, debris will be THROWN at

you, drag will slow the engine down, and you

will use up a lot of line.

Use only quality nylon monofilament line of

the diameter 2.5mm. Never use wire or wire-

reinforced line in place of nylon trimmer line.

Load your nylon line cutting head only with

nylon trimmer line of the proper diameter

.

Use extreme caution when operating over bare

spots and gravel,because the line can throw

small rock particles at high speeds.

Debris shields on the unit cannot stop

objects which bounce or ricochet off hard

surfaces.

For nearly all cutting, it is good to tilt the line

head so that contact is made on the part of

the line circle where the line is moving AWAY

from you and the debris shield. (See appropraite

picture) This results in the debris being thrown

AWAY from you.

○

○

○

○

TRIMMING

This is feeding the trimmer carefully into the

material you wish to cut.Tilt the head slowly to

direct debris away from you. If cutting up to a

barrier such as fence, wallor tree,approach from

an angle where anydebris ricocheting off the

barrier will fly away from you.Move the line head

TO WALL

ANGLE

GROUND

RAISED

KNIFE SIDE

TRIMMING

ANGLE TO

DEBRIS

Trimming can be done to cut through weed

stems one at a time. Place the trimmer line

head near the bottom of the weed-never high up

which could cause the weed to chatter and catch

the line. Rather than cut the weed right through,

justuse the very end of the line to wear through

thestem slowly.

SCALPING

EDGING

WARNING

Do not to use a steel blade for edging or

scalping.

SCALPING AND ENGING:

Both of these are done with the line head

tilted at a steep angle Scalping is removing top

growth leaving the earth bear.

Edging is trimming the grass back where ithas

spread over a sidewalk or drive way.

During both edging and scalping, hold the unit

a steep angle and in a position where

t

hedibris,

and any dislodging dirt and stones,will not come

Summary of Contents for KZ-4000BC-PRO-2S

Page 3: ...1 2 3 8 7 5 6 4 3 2 1 6 5 4 9 8 7 1 0 1...

Page 4: ...9 1 0 1 1 1 2 1 3 1 4 1 5 1 6 1 6 3 1 2 1 1 1 5 1 4 1 7 1 6 1 2...

Page 5: ...3...

Page 6: ...2 9 3 0 3 1 2 3 1 3 0 3 5 3 4 3 3 3 7 3 6 3 3 8 4...

Page 23: ...21 KASEI BRUSH CUTTER KZ 4000BC PRO 2S ENGINE DIAGRAM...

Page 34: ...32 Small Maintenance Big Savings Small Maintenance Big Savings Small Maintenance Big Savings...

Page 35: ......