8 / 12

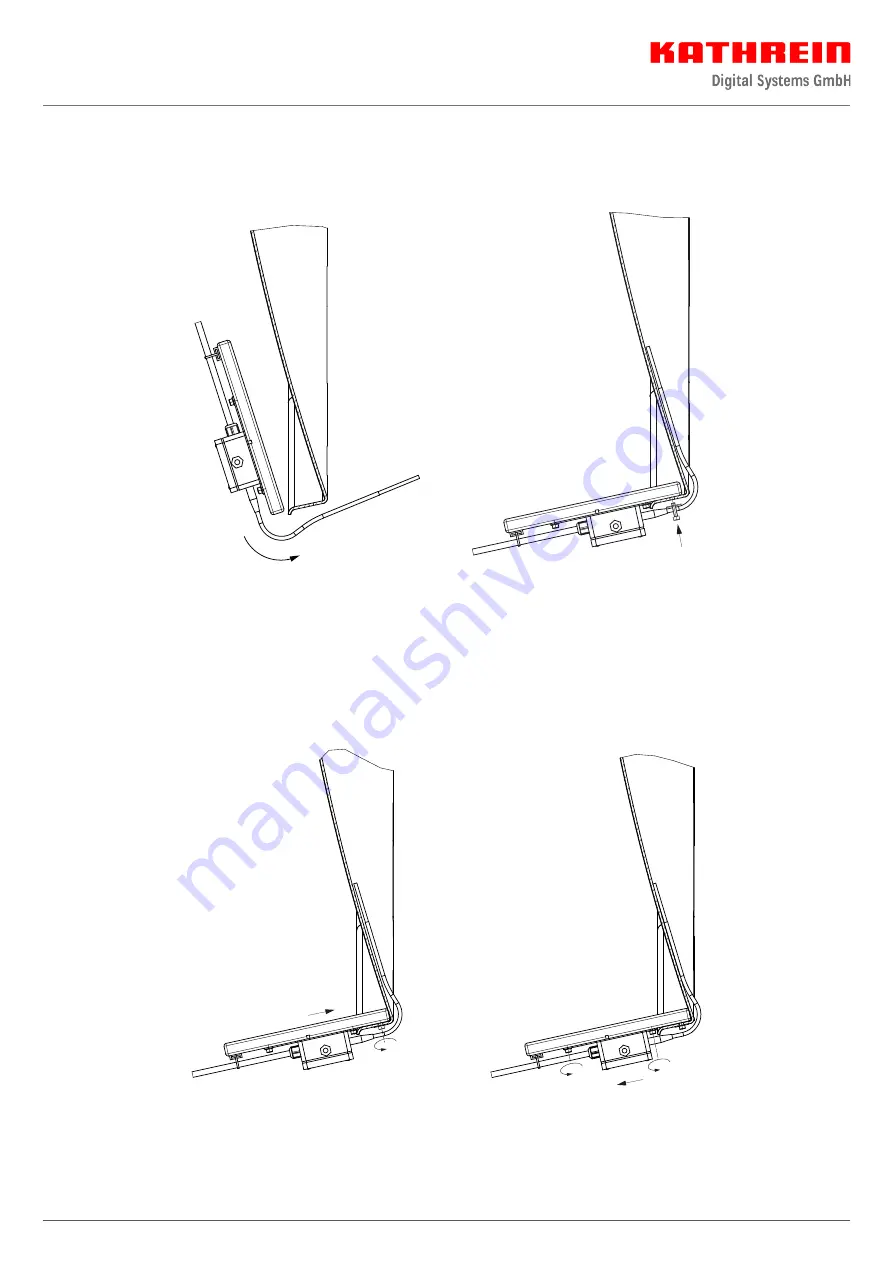

Installation

1. Pivot the sensor unit over the edge of the reflector (Fig. 1), guide the screw and washer (1) through the pre-drilled hole and screw

into the aluminium profile (Fig. 2) but do not tighten securely yet

Fig. 1

Fig. 2

2. Slide the aluminium profile up to the reflector plate and securely tighten the screw (1) (M

A

= 5 Nm) (Fig. 3).

3. Slide the sensor housing and plate in the aluminium profile until the ends of the two electrodes are located on the reflector

surface and under tension, then securely tighten the screws (2 + 3) again (M

A

= 5 Nm) (Fig. 4).

4. Securely tighten the cable tie (4) on the unit.

Fig. 3

Fig. 4