41

SIKAFLEX

®

291 TECHNICAL DATA SHEET

Si

kafle

x

®

-291

2

/

2

Weitere Informationen

Internet: www.sika-industry.de, E-Mail: industry@de.sika.com

www.sika.com

Sika Deutschland GmbH

Kleb- und Dichtstoffe Industrie

Stuttgarter Strasse 139

D-72574 Bad Urach

Deutschland

Tel. +49 7125 940-761

Fax +49 7125 940-763

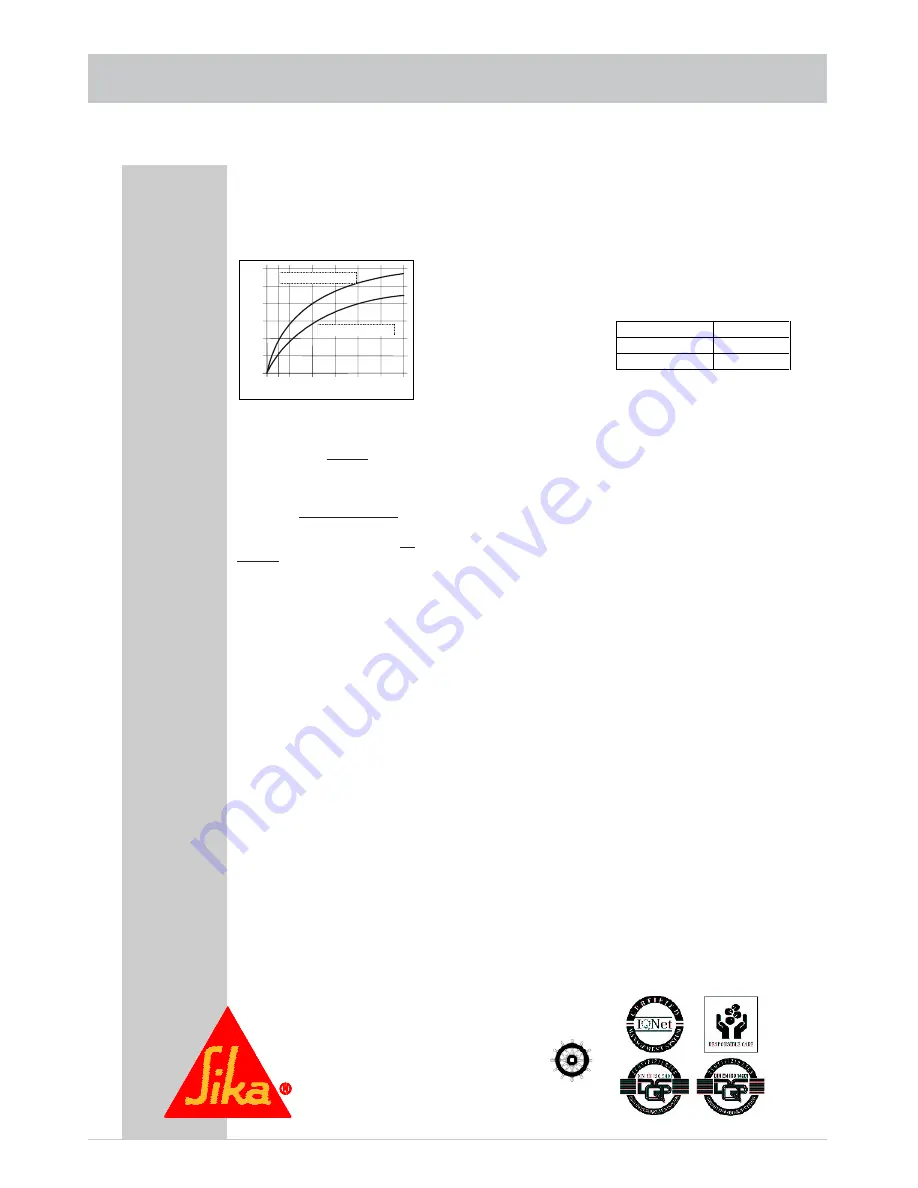

Die Vernetzungsreaktion von Si-

kaflex

®

-291 erfolgt mit Luftfeuch-

tigkeit. Bei niedriger Temperatur ist

der Wassergehalt der Luft geringer

und die Vernetzungsreaktion ver-

läuft etwas langsamer (siehe Dia-

gramm).

Zeit (Tage)

12

10

8

6

2

4

0

4

8

12

0

Schichtdicke

(mm)

23°C / 50% r.Lf.

10°C / 50% r.Lf.

Diagramm 1: Durchhärtegeschwindigkeit für

Sikaflex

®

-291

Chemische Beständigkeit

Sikaflex

®

-291 ist beständig gegen

Süss- und Salzwasser, Kalkwasser

und öffentliche Abwässer sowie

wässerige Tensidlösungen, ver-

dünnte Laugen und Säuren; kurz-

zeitig beständig gegen Treibstoffe,

Mineralöle sowie pflanzliche und

tierische Fette und Öle, nicht be-

ständig gegen organische Säuren,

Alkohol, stärkere Mineralsäuren

und Laugen sowie Lösemittel.

Die Informationen sind nur An-

haltspunkte. Eine objektbezogene

Beratung erhalten Sie auf Anfrage.

Verarbeitungshinweise

Untergrundvorbereitung

Die Haftflächen müssen sauber,

trocken, staub- und fettfrei sein.

Angaben zur Vorbereitung von

Werkstoffoberflächen finden Sie in

der Primertabelle für Sika

®

Marine

Systeme.

Verarbeitung

Kartuschenmembrane einstechen

und vollständig öffnen.

Beutel in die Verarbeitungspistole

einlegen und Clip abschneiden.

Düsenspitze entsprechend der Fu-

genbreite zuschneiden und die

Dichtmasse mit einer geeigneten

Hand-, Akku- oder Kolbenstangen-

druckluftpistole luftfrei in die Fuge

einbringen.

Angebrochene Gebinde müssen

innerhalb weniger Tage verarbeitet

werden.

Die Verarbeitungstemperatur darf

5°C nicht unter- bzw. 40°C nicht

überschreiten. Die optimale Tem-

peratur von Material und Werkstoff

liegt zwischen 15°C und 25°C.

Für die Beratung zur Auswahl und

Einrichtung

einer

geeigneten

Pumpanlage setzen Sie sich bitte

mit der Abteilung System Enginee-

ring der Sika Industry in Verbin-

dung.

Abglätten

Das Abglätten muss innerhalb der

Hautbildezeit des Klebstoffes er-

folgen. Zum Abglätten empfehlen

wir Sika

®

Abglättmittel N. Andere

Abglättmittel müssen auf ihre Eig-

nung überprüft werden.

Entfernung

Nicht ausgehärtetes Sikaflex

®

-291

kann von Geräten und Werkzeu-

gen mit Sika

®

Remover-208 ent-

fernt werden. Ausgehärtetes Mate-

rial kann nur noch mechanisch

entfernt werden.

Hände/Haut sollten sofort mit

Sika

®

Handclean oder einer geeig-

neten Handwaschpaste und Was-

ser gereinigt werden. Keine Löse-

mittel verwenden!

Überlackieren

Nach erfolgter Hautbildung kann

Sikaflex

®

-291 überlackiert werden.

Die Lackverträglichkeit muss durch

Vorversuche

überprüft

werden.

Einbrennlacke dürfen nur auf völlig

ausgehärtetem Sikaflex

®

-291 auf-

gebracht werden. Es ist zu berück-

sichtigen, dass Härte und Filmdi-

cke des Lackes den Klebstoff in

seiner Dehnung beeinträchtigen

und zu Rissbildungen führen kön-

nen.

Weitere Informationen

Folgende Dokumente sind auf

Anfrage erhältlich:

-

Sicherheitsdatenblatt

-

Primertabelle für Sika Marine

Systeme

-

Allg. Richtlinien zur Verarbeitung

von Sikaflex

®

Kleb- und Dicht-

stoffen

-

Marine Handbuch

Gebinde

Tube

100 ml

Kartusche

310 ml

Beutel

400 ml

Wichtig

Für den Umgang mit unseren

Produkten sind die wesentlichen

physikalischen, sicherheitstechni-

schen, toxikologischen und ökolo-

gischen Daten den stoffspezifi-

schen Sicherheitsdatenblättern zu

entnehmen.

Die

einschlägigen

Vorschriften, wie z.B. die Gefahr-

stoffverordnung, sind zu beachten.

Auf Wunsch stellen wir Ihnen un-

ser System-Merkblatt TM 7510

"Hinweise

zum

Arbeitsschutz"

beim Umgang mit Produkten der

Sika Deutschland GmbH zur Ver-

fügung.

Hinweis:

Die vorstehenden Angaben, insbesondere

die Vorschläge für Verarbeitung und Ver-

wendung unserer Produkte, beruhen auf

unseren Kenntnissen und Erfahrungen im

Normalfall,

vorausgesetzt

die

Produkte

wurden sachgerecht gelagert und ange-

wandt. Wegen der unterschiedlichen Mate-

rialien, Untergründen und abweichenden

Arbeitsbedingungen kann eine Gewährleis-

tung eines Arbeitsergebnisses oder eine

Haftung, aus welchem Rechtsverhältnis auch

immer, weder aus diesen Hinweisen, noch

aus einer mündlichen Beratung begründet

werden, es sei denn, dass uns insoweit

Vorsatz oder grobe Fahrlässigkeit zur Last

fällt. Hierbei hat der Anwender nachzuwei-

sen, dass er schriftlich alle Kenntnisse, die

zur sachgemäßen und erfolgversprechenden

Beurteilung durch Sika erforderlich sind, Sika

rechtzeitig und vollständig übermittelt hat.

Der Anwender hat die Produkte auf ihre

Eignung für den vorgesehenen Anwen-

dungszweck zu prüfen. Änderungen der

Produktspezifikationen bleiben vorbehalten.

Schutzrechte Dritter sind zu beachten. Im

übrigen gelten unsere jeweiligen Verkaufs-

und Lieferbedingungen. Es gilt das jeweils

neueste Technische Merkblatt, das von uns

angefordert werden sollte.

The cross-linking reaction of Sikaf-

lex

®

291 occurs in the presence of

atmospheric moisture. At lower tem-

peratures the water content of the air

is less and the cross-linking reaction

proceeds somewhat more slowly (see

diagram).

Layer thickness (mm)

Time (days)

Diagram 1: Through curing speed of

Sikafl ex

®

291

Chemical Stability

Sikafl ex

®

291 is resistant to fresh

water and salt water, hard water and

effl uent from public drains including

aqueous surfactants, dilute alkalis

and acids; short-term resistant to

fuels, mineral oils including vegeta-

ble and animal oils and greases, not

resistant to organic acids, alcohol,

stronger mineral acids and alkalis or

solvents. This information is intended

only as a general indication. Advice

for specifi c applications is available

on request.

Processing instructions

Substrate preparation

The surfaces to be bonded must be

clean, dry, and free of dust and gre-

ase. Data on preparation of materials

surfaces can be found in the primer

table for Sikafl ex

®

marine systems.

Processing

Break the cartridge membrane and

fully open it. Insert the bag into the

application gun and cut off the clip.

Cut off the tip of the nozzle to suit

the crack to be fi lled, and apply the

sealant with a suitable manual, bat-

tery-powered or compressed air pi-

ston gun into the crack, leaving no

air bubbles. Opened containers must

be used up within a few days. The

processing temperature must not be

below 5°C or above 40°C. The opti-

mum temperature both material and

sealant is beween 15°C and 25°C.

For advice on selection and arran-

gement of a suitable pump system,

please contact the System Enginee-

ring Department at Sika Industry.

Smoothing off

Smoothing off must be performed

within the skin formation time of the

adhesive. We recommend Sika

®

N

smoothing off agent. Other smoothing

off agents should be checked for sui-

tability before use.

Removal

Uncured Sikafl ex

®

291 can be remo-

ved from equipment and tools with

Sika

®

Remover 208. Cured material

can only be removed machanically.

Hands/skin should be cleaned im-

mediately with Sika

®

Handclean or

a suitable hand cleansing paste and

water. Do not use solvents!

Painting over

After the skin has formed, Sikafl ex

®

291 can be painted over. The suitabli-

lity for painting over must be trialled

prior to application. Powder coating

points may be applied only to fully

cured Sikafl ex

®

291. It should be

borne in mind that the hardness and

fi lm thickness of the paint fi nish may

affect the expansion of the plastic and

lead to cracking.

Additional information

The following documents are availa-

ble on request:

- Safety data sheet

- Primer table for Sika marine

systems

- General guidelines for working with

Sikafl ex

®

adhesives and sealants

- Marine handbook

Containers

Tube

Cartridge

Bag

Important

When handling our products, please

read the material-specifi c safety data

sheets for their essential physical, sa-

fety, toxicological and ecological data.

The applicable regulations, such as

the hazardous substances regula-

tions should be complied with. On

request we will send you our system

data sheet TM 7510 „Instructions for

protection at work“ for handling Sika

Deutschland GmbH products.

Note:

The details above, especially the suggestions for

the processing and use of our products are based

on our knowledge and experience in normal cases,

providing the products are correctly stored and ap-

plied. Due to the variety of materials, surfaces and

variations in working conditions, no guarantee of a

work product or liability from any legal relationship

can be founded on these instructions or on oral

advice unless we are charged with premeditated

or gross negligence. Here the user must prove that

he brought to Sika‘s attention promptly, completely

and in writing all knowledge necessary for Sika to

make an objective assessment of expectation of

success. It is the user‘s responsibility to check the

products for suitability for the intended application.

We reserve the right to change the product specifi -

cations. The trademark rights of third parties must be

respected. In all other respects our respective sales

and delivery conditions apply. The latest version of

the technical data sheet is applicable and should be

requested from us.

Additional information

Internet: www.sika-industry.de, e-mail: industry@de.sika.com

www.sika.com

Sika Deutschland GmbH

Kleb- und Dichtstoffe Industrie

Stuttgarter Strasse 139

D-72574 Bad Urach

Germany

Tel. +49 7125 940-761

Fax +49 7125 940-763