Page 44

Copyright © 2012 Kato Engineering, Inc. All rights reserved

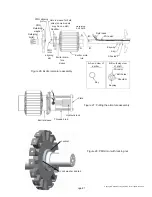

6. Connect the exciter armature wires to the rectifi er terminals.

7. If the generator has a PMG, place it onto the end of the exciter

sleeve. Make sure it is aligned with the pin slot in the end of the

exciter sleeve.

8. Install the retaining washer and bolt, and torque (60 ft-lbs for a 1/2-

inch diameter bolt; 200 ft-lbs for a 3/4-inch diameter bolt).

9. Install the exciter frame/stator and/or exciter-PMG frame/stator.

Install the clips securing the exciter fi eld leads to the exciter frame

and endbracket and connect the leads.

10. Measure the air gap between the exciter armature and exciter fi eld

and between the PMG rotor and PMG stator. If the air gap of the

armature is less than specifi ed in Table 5 or if the air gap of the PMG

is less than 0.020 inch, check 1) generator-engine alignment, 2)

check for bearing wear, 3) check for misalignment of the armature,

PMG or stator.

11. Install the exciter cover.

Exciter armature

diameter (in.)

0.014

0.014

0.018

0.035

Minimum air gap

(in.)

Table 5: Exciter air gap

5 3/4

9 7/8

12 1/2

16 1/4

IMPORTANT:

IMPORTANT: To measure air gap, measure

completely around the gap between the

exciter armature and exciter fi eld with a

feeler gauge. Keep the gauge at the tightest

point, and turn the generator over to mea-

sure the air gap as the rotor turns.

WARNING: Do not pry on the genera-

tor fan blades. Blades can weaken which

could result in serious injury or death from

fl ying debris