1 – 20

ᵏ

SAFETY

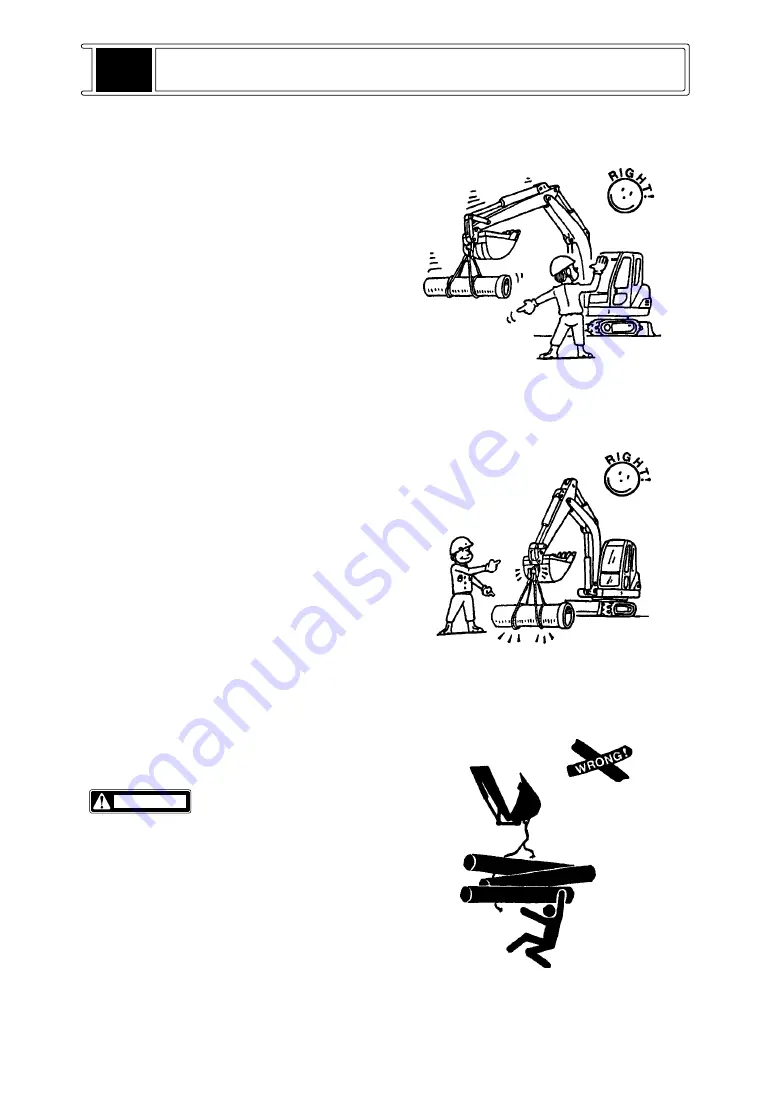

LIFT COORDINATOR

One person should assume responsibility for

coordinating all facets of the lift. He must take

into consideration the operator, the machine,

other personnel. bystanders and the

surrounding area. He must be totally alert to

the hazards involved, have in-depth

knowledge of proper procedures and exercise

good common sense all time.

DO NOT OVERLOAD LIFTING.

Prominent among the safety measures

unique to hydraulic excavators is the sole

reliance upon the manufacturer’s load rating

chart as a guide to lifting capacity. Relying

upon signs of tipping to warn of overload can

result is machine damage or personal injury.

Lifting capacity in excavators is usually

determined by hydraulic and structural fitness,

not tipping load. Before making a list,

ALWAYS

consult the load rating chart in the

operator’s cab.

Stay within the lifting limits when laying pipes.

Remember, you may be able to lift the pipe

close in at ground level, but as you reach out

and down, the lifting capacity decrease. If the

machine is not on level ground. an instability

will result, which could cause tipping. always

use short slings to prevent excessive load

swing.

There may be some local government

regulations regarding the use of excavators

to lift heavy objects. Please observe those

regulations where they apply.

CHECK THE SLING CABLE AND DEVICES.

ALWAYS

be certain that slings, ties and

hooks are properly placed, secure, of

adequate capacity and good condition before

lifting materials

CAUTION

Summary of Contents for 17VXE

Page 2: ......

Page 62: ...2 1 8 ...

Page 110: ...5 1 HYDRAULIC SYSTEM DIAGRAM 5 1 HYDRAULIC SYSTEM DIAGRAM 2 9 30 ...

Page 118: ...MINI EXCAVATOR 17VXE PUBLISHED MARCH 2017 KATO IMER S p A ITALY ...

Page 119: ......

Page 120: ......