3 – 9

MAINTENANCE

DAILY

3-4 DAILY MAINTENANCE AND CHECKS

Check the Engine Oil Level

* Check the oil level with the engine stopped.

DO

NOT

check the oil level with engine running.

*

DO NOT

overfill the crankcase to avoid engine

damaged. Engine damage can result.

*

NEVER

operate the engine when oil level is

above

MAX

or

MIN

marks.

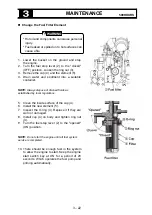

1. Place the machine on level ground. Stop the

engine.

2. Remove the dipstick

c

and wipe it clean. Insert

dipstick

c

, then remove it again to read actual

oil level. Install dipstick

c

.

3. Maintain the oil level to the

MAX

mark on the

dipstick

c

. Add oil if necessary.

4. Remove the oil fill plug and add oil.

Clean and install the oil fill plug .

5. Close the access door.

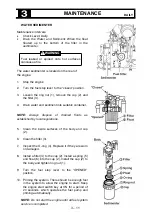

Check the Coolant Level

* Steam generated by hot fluid under pressure in

radiator can cause personal injury.

* Remove filler cap only when cool enough to

touch with bare hand.

1. Open the access door on the rear of the

machine.

2. Always check the coolant level in the reserve

tank. Maintain the coolant level between the

MAX

and

MIN

marks on the reserve tank.

3. Remove the coolant fill cap and add the

coolant if necessary.

4. If the reserve tank is empty, check the radiator

level with the engine stopped. Add coolant to

the radiator and the reserve tank.

5. Close the access door.

WARNING

CAUTION

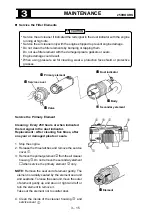

Oil level gauge

Fill neck

Reserve tank level

Water

supply

port

Upper

limit

Lower

limit

c

c

c

c

c

Dipstick

MAX

MIN

Check oil level at least 15 min after engine

stopping.

Summary of Contents for 17VXE

Page 2: ......

Page 62: ...2 1 8 ...

Page 110: ...5 1 HYDRAULIC SYSTEM DIAGRAM 5 1 HYDRAULIC SYSTEM DIAGRAM 2 9 30 ...

Page 118: ...MINI EXCAVATOR 17VXE PUBLISHED MARCH 2017 KATO IMER S p A ITALY ...

Page 119: ......

Page 120: ......