WARNING

・

You must read and understand this manual before operating

or servicing this crane.

If you do not do so, you may cause serious injury or death

including damage to the equipment etc.

・

All people who come into contact with this crane must read

and be familiar with the contents of this manual. Keep it in

the crane so it will be available to anybody who needs it.

・

If you need a copy of this manual in another language, ask

your authorised KATO dealer.

218711

Applicable serial No.: 0051

-

Machine Section

Summary of Contents for PREMIUM CITYRANGE CR-200RF

Page 2: ...218711 背厚 14 5 mm 中 ...

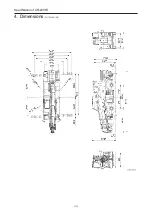

Page 14: ... 12 4 Dimensions T217591 021 0E Specification of CR 200Rf ...

Page 16: ... 14 MEMO ...

Page 24: ... 22 MEMO ...

Page 30: ... 4 MEMO ...

Page 36: ... 10 MEMO ...

Page 38: ... 12 3 General operation devices 2 Outside the cab ...

Page 60: ... 34 MEMO ...

Page 74: ... 48 MEMO ...

Page 82: ... 56 7 Air conditioner 7 6 Display when errors are detected T217921 020 0E ...

Page 120: ... 94 MEMO ...

Page 129: ... 102 MEMO ...

Page 138: ... 111 17 Drive operation devices Drive operation devices ...

Page 139: ... 112 17 Drive operation devices ...

Page 153: ... 126 17 Drive operation devices ...

Page 154: ... 127 17 Drive operation devices Drive operation devices ...

Page 237: ... 208 21 Crane operation devices 21 Crane operation devices 061A 0005 0E 1 Inside the cab ...

Page 238: ... 209 21 Crane operation devices Crane operation devices ...

Page 239: ... 210 21 Crane operation devices 2 Outside the cab ...

Page 259: ... 230 22 Crane operation when the outriggers are used ON OFF ...

Page 299: ... 270 24 Crane operation NOTE Extension retraction sequence for each boom length ...

Page 320: ...26 Preoperational checks Pre drive checks 290 ...

Page 321: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 291 ...

Page 322: ...26 Preoperational checks Pre drive checks 292 ...

Page 329: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 299 ...

Page 330: ...26 Preoperational checks Pre drive checks 300 ...

Page 331: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 301 ...

Page 332: ... 302 MEMO ...

Page 340: ... 310 MEMO ...

Page 342: ...899 92187110 ...