-4-

(3) 維修工作時。

(4) 離開工作場所或工作場所無人看顧

時。

8. 假如不慎讓機器及配件使用之油或油

脂,接觸到眼睛、皮膚貨誤食時,請立

刻以水清洗接觸部位及就診。

9. 請勿擅自碰觸運轉中之零件或配件及

注意機器電源是否已開啟,以免導致人

員受傷。

10. 維修、修改及調整等工作,須由受過

適當訓練的技師或熟手為之。維修時只

許使用指定之零件。

11. 一般維修及檢查工作必須由受過適當

訓練的人員為之。

12. 電子零件維修及保養工作必須由資深

的電子技師為之,或由非常熟練的人員

檢查及指導,當發現零件損壞時,請立

刻停止機器運轉。

13. 在做裝有氣動式零件 ( 例如氣缸 )

機器的維修及保養工作前,機器連接

空壓機及高壓空氣必須予以關閉及卸

除,機器中殘存高壓氣體必須予以消

除,此外調整及性能檢查只能由受過

適當訓練的技師或熟手為之。

14. 機器使用一段時間,必須定期清理。

(3) When repairing.

(4) When the operator leaves the

working place or leaves the

machine unattended.

8. If grease, oil, or any fluid contacts

your skin or eyes by any chance,

please wash the contacted area

completely with clean water and

consult a doctor. Or, swallow any fluid

mistakenly, consult a doctor

immediately.

9. Do not touch any functioning parts

and devices. Always attend to

whether power switch is on or off

before operating in order to prevent

anyone from getting hurts.

10. Qualified technicians are required

for adjustment, modification, and

repair. Only use assigned parts for

replacement.

11. Routine maintenance and service

must be performed by well trained

persons, or qualified technicians.

12. Maintain and check the electronic

parts must be done by qualified

electrician or well-trained persons. If

any electronic part damaged or

malfunctioned, stop the machine

immediately.

13. The air house has to be detached

from the machine and the

compressor or air supply has to be

cut off before repairing and servicing

the machine equipped with

pneumatic parts such as an air

cylinder. Qualified technicians or

well-trained persons are required for

adjustment and repairs.

14. To ensure the best performance,

periodically clean the machine is

necessary.

Summary of Contents for Siruba LF-D6

Page 1: ...LF D6 使用說明書與零件圖 INSTRUCTION BOOK PARTS LIST ...

Page 2: ......

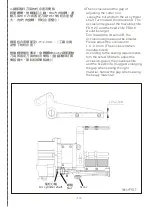

Page 14: ... 10 接管圖 WIRINGDIAGRAM ...

Page 33: ... 29 ...

Page 34: ... 30 ...

Page 35: ... 31 ...

Page 36: ... 32 ...

Page 37: ... 33 ...

Page 38: ... 34 ...

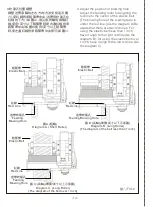

Page 39: ... 35 桌板圖 TABLE CUT OUT OF 747S T5 ...

Page 40: ......

Page 41: ......