SAP 100104

en

Operating Manual

Original Operating Manual

1

Edition 07/15

Subject to modifications

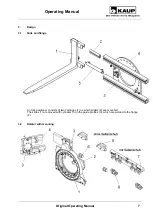

Rotating Fork Positioner

2T456Z, 2T456ZA, 2T496Z, 2T496ZA

T456Z

T496Z

Rotating Fork Positioner without sideshift

Rotating Fork Positioner with sideshift

T456ZA

T496ZA

Rotating Fork Positioner without sideshift with bolt-on forks

Rotating Fork Positioner with sideshift with bolt-on forks