Operating Manual

Original Operating Manual

17

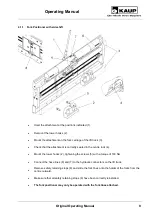

6.3.4 Fork carriage

Yearly

Check the ISO strips at the fork carriage (8) for wear.

Render the fork positioner inoperative when at least one of the three wear limits

c2, k2, or d2 is underrun.

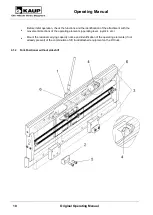

Wear limit (z) in [mm]

ISO-Kl.2

ISO-Kl.3

ISO-Kl.4

c2

k2

d2

c2

k2

d2

c2

k2

d2

13.5 11.5

9.3

18.5 14.5 13.2

22.0 17.5 15.6

As necessary

For replacing the fork carriage, please contact our service department.