Operating Manual

4

Original Operating Manual

1.

Introduction

1.1

Working with this manual

This operating manual contains important information on how to operate the attachment properly,

safely and efficiently.

The operating manual shall be read, understood and applied by all personnel working on or with the

equipment, for example:

Installation and operating the equipment

Inspection, maintenance and repair

Transport and disposal

The manual must be kept available for ready reference at the equipment’s place of use.

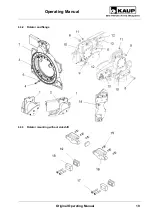

The illustrations in this operating manual may deviate from the actual version

of the equipment.

1.2

Warning notes and symbols

The following symbols are used in this operating manual to highlight details of special importance:

Identifies details relating to do’s and don’ts for the purpose of avoiding injury

and property damage.

Specific details relating to the efficient use of the attachment and other advice.

Lists are denoted by a shadowed box.

Steps to be performed by the operator are denoted by a black dot.

(1)

In illustrations, particular elements have numbered pointers. Numbers in brackets in

the text refer to the corresponding elements.

1.3

Copyright

This documentation including all parts is copyrighted. Any use or change outside the narrow limits of

copyright law without permission from KAUP GmbH & Co KG is forbidden and liable to prosecution.

This applies, in particular, to reproduction, translation, microfilming as well as storage and

processing in electronic systems.