Controls

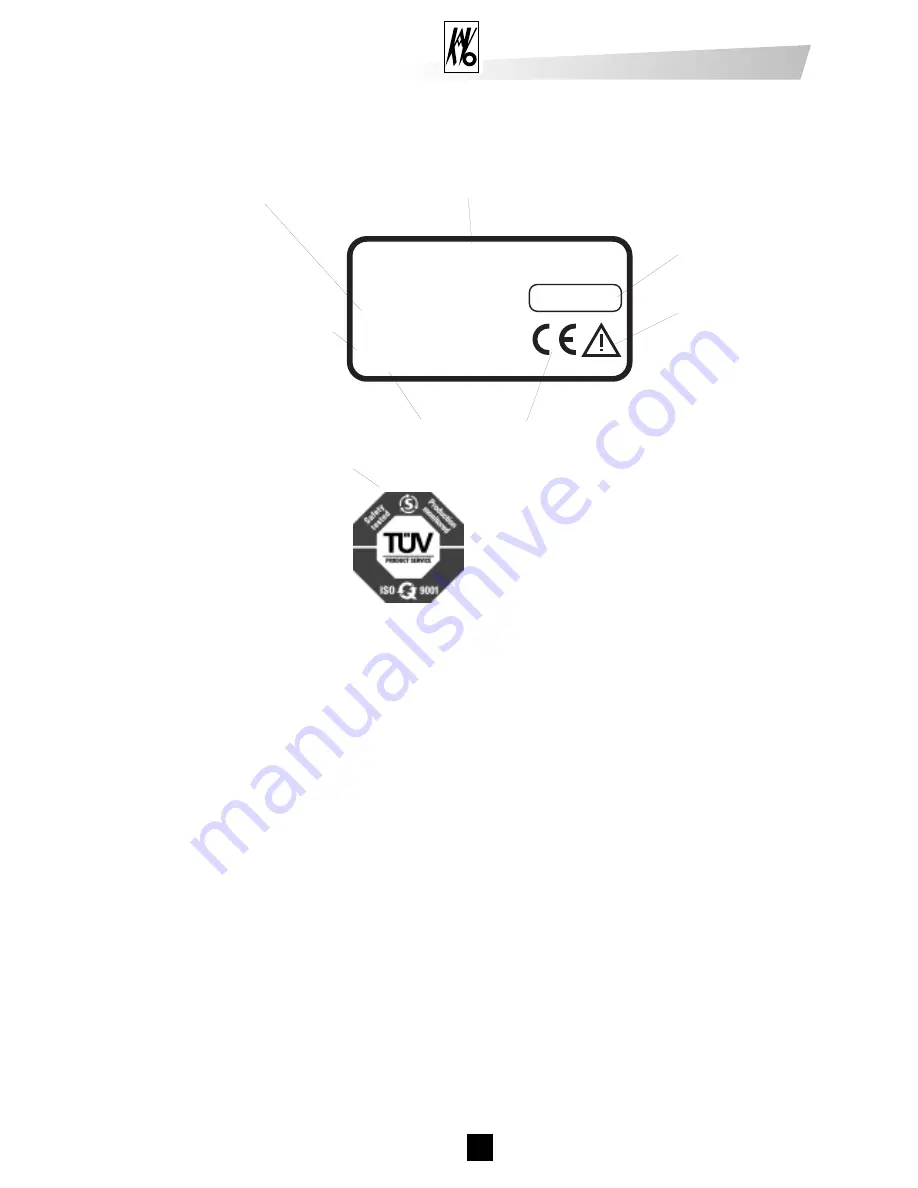

A 3.1 Rating plate

The device has been tested for conformity with

the requirements of the European standards by

the TÜV product service.

EN 50178 : 1997

Report No.: 014 100 56 208

KaVo ELEKTROTECHNISCHES WERK GMBH

D-88299 Leutkirch im Allgäu

S-No.

Type EWL 4452

No. 0.641.7700

230 V~ 50/60 Hz

16 A

Made in Germany

Hersteller/

manufacturer

Gerätetyp/

Device type

Seriennummer/

Serial number

Warnhinweis:

Begleitpapiere

beachten/

Warning:

see accompanying

documents

CE-Kennzeichnung/

CE mark

Stromaufnahme/

Current consumption

Max. mögl. Gerät-Ver-

sorgungsspannung (diese

Angabe ist länder-

spezifisch und kann von

der Abbildung abweichen)

Max. possible device

supply voltage (this is

country-specific and may

differ from the Figure)

TÜV-Zeichen/

TÜV symbol

9