2

EWL 5839

A 1 Features

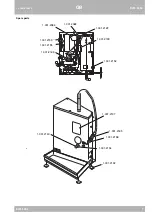

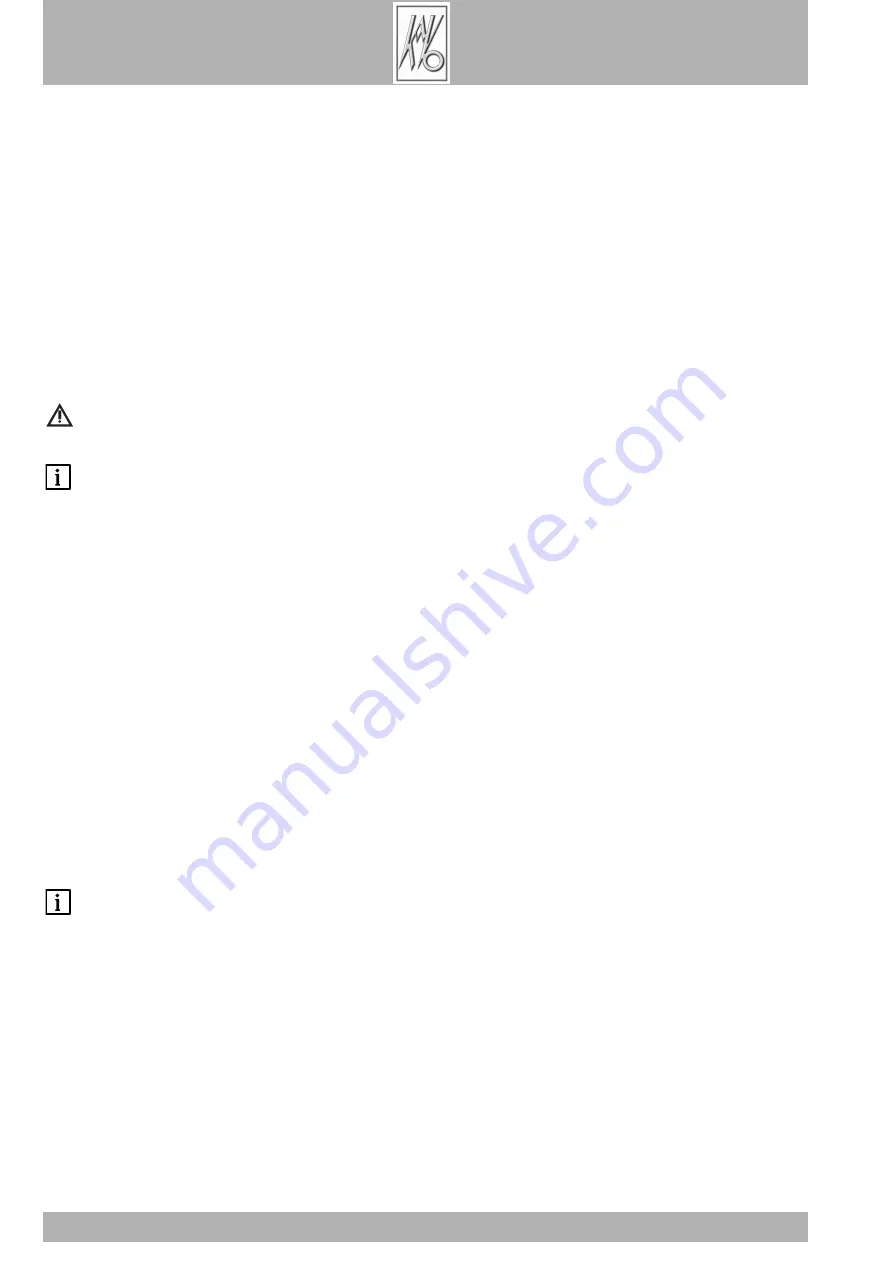

Steam Cleaner EWL 5839 is designed for problem-free operation using dry or wet steam.

It is suitable for cleaning, boiling out or removal of greasy substances in all procedures of dental technology. The unit generates dry steam

to a maximum temperature of 164° C at a pressure of 6 bar. The unit can be set on a bench top, or wall-mounted. Due to the automatic

water supply, the unit is ready for operation throughout the day. The combined pressure and temperature indicator enables checking of the

operating temperature and pressure, even if the unit is switched off.

A 2 For your safety

A 2.1 Observance of the Operating Instructions

Each user of the unit is assumed to have a thorough knowledge and observance of these operating instructions. The unit is designed only

for the applications described. In these operating instructions, particularly important comments are illustrated as follows:

Warning! This is a warning relating to risky and dangerous situations. Non-compliance with this warning can lead to life-

threatening situations.

These warnings must be strictly observed.

Information! This is information relating to specific characteristics to be observed.

A 2.2 Safety considerations

• The unit is designed for use with an electrical supply of 230V / 50Hz. Ensure that your unit is always supplied with the correct voltage.

• The electrical plug must be removed before maintenance and cleaning.

• Safety features:

- If leakage occurs, a moisture sensor automatically switches the unit off.

- A temperature safeguard shuts the unit down at temperatures above 192° C.

- If the operating pressure rises above 7 bar, the unit switches off automatically.

- A safety valve opens automatically in the pressure chamber at an operating pressure of more than 9 bar

.

A 2.3 Liability for function and damage

If the unit is improperly maintained, repaired, or altered by an unqualified person; or is used for purposes for which it was not designed,

then the responsibility for proper function is solely carried by the owner or operator of the unit.

The unit must be maintained and operated in accordance with these operating instructions.

KaVo EWL is not liable for damage arising as a result of non-compliance with the above information.

Guarantee and liability conditions as described in the Sales and Delivery Conditions from KaVo EWL are not extended through the above

information.

Ensure that these operating instructions are available at all times, are read, and understood.