GB

OPERATING INSTRUCTIONS

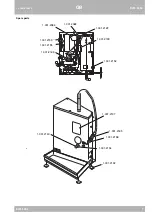

EWL 5839

5

A 8 Care of the unit

Before cleaning or maintaining the unit, let it cool down!

A 8.1 Cleaning

In order to ensure trouble-free operation, the unit should be cleaned at regular intervals, using a mild detergent with a sponge or soft cloth.

Do not use any chemicals.

The collecting tray can be removed from the unit for cleaning.

One version of the unit comes with a collection drawer and lid – to clean, simply pull it out.

The nameplate must always be legible and never be removed.

A 8.2 Maintenance

An integral part of the KaVo Steam Cleaner is a special technique to prevent build up of lime, therefore, at least once a week, minor lime

particles should be flushed out. It is not necessary to drain the water.

However, if it does become necessary to drain the chamber, please note the following:

Check the manometer to ensure that the unit has cooled down, and that the drain hose leads to a heat-resistant bucket or to a sink.

For your own safety, it is recommended to permanently install the drain hose as water and steam from a unit that has not cooled down is

very hot – approx. 164° C.

Using the square socket wrench, turn the drainage valve from its locked position 90° in an anti-clockwise direction – at the same time

pressing on the footswitch until no more water flows.

Re-lock the valve by turning 90° in a clockwise direction.

An additional feature advises when rinsing is necessary:

If you have not carried out the weekly rinsing, after 200 hours of use an electronic operating-hours meter warns that rinsing is necessary.

This is indicated by the permanent flashing of the yellow dry/wet-steam control light together with the red low-water level control light.

The meter can be set back to “0“ (see RESET)

Further use of the unit is possible, however, without problems.

Rinsing procedure (summary only – see sticker on left side of housing)

Rinsing the unit is best carried out in a cold condition, before use. Otherwise, switch unit off and let it cool down until it is virtually

pressure-free (under 2 bar).

Open the water faucet, and switch the unit on.

Using the square socket wrench, open the drainage valve on the left side of the housing by turning a complete 90° to the second stop. In

the process, press the safety-lock button at the right of the valve.

Pressing once partly opens the valve (safety lock – danger of scalding!); to completely open the valve, press the button again.

Hold the black rinsing key at the left of the valve pressed down until only clear water flows out of the drainage hose. Close the valve by

turning it back 90°.

Now proceed in accordance with

A 5

(Putting into operation) and

A 6

(Operation).

Re-setting the operating-hours meter = RESET

Switch the unit off.

Hold the dry-steam key pressed – at the same time switch unit on.

Operating hours count starts from zero.

The safety valve for the pressure chamber must be tested for proper function at regular intervals by a Service Technician!

Technical modifications reserved