Instructions for use INTRA K-LUX 200 – 1.000.6717, INTRA K-LUX 200 F – 1.002.1912

5 Operation | 5.1 Connecting the motor to the supply hose

16 / 28

5 Operation

NOTE

At the beginning of each workday, the water-conducting systems should be

rinsed for at least 2 minutes (without transmission handpieces being at-

tached) and if there is a risk of contamination from reflux or back suction, the

system may also need to be rinsed for 20 to 30 seconds after each patient.

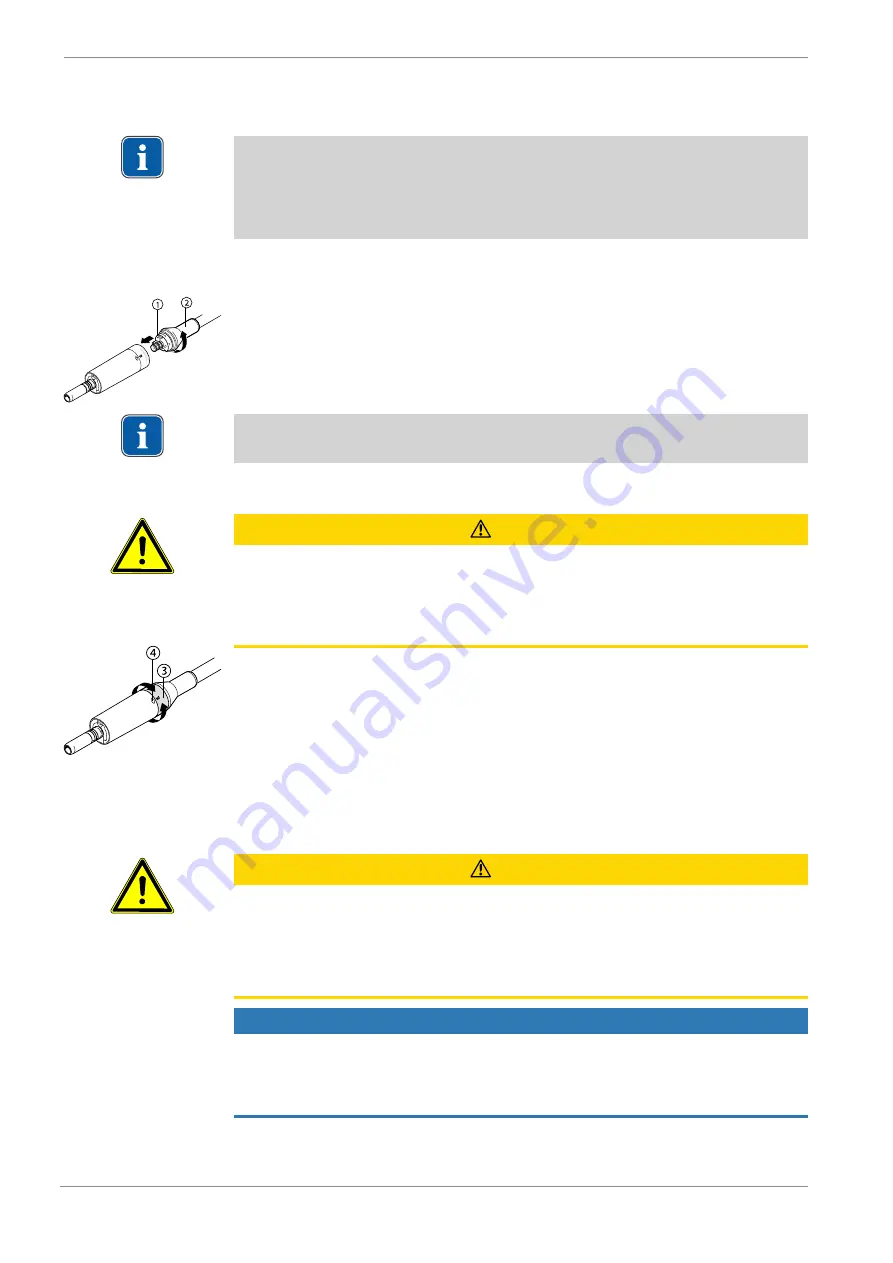

5.1 Connecting the motor to the supply hose

4

Apply a small amount of KaVo Spray to the O-rings on the supply hose.

4

Insert the plug-in connector

①

into the motor bearing end plate while noting

the position of the plug contacts.

4

Screw the screw joint

②

tightly in the direction of the arrow.

NOTE

Details on the hose coupling can be obtained from the manufacturer.

5.2 Regulating the spray water

CAUTION

Hazard from insufficient amount of spray water.

Damage to the cog due to overheating.

4

Make sure that the motor speed is appropriate for the preparation on hand.

4

Use the requisite minimal amount of spray water.

4

Rotate the regulating sleeve

③

right or left to adjust the water portion of the

spray continuously.

ð

When the regulating ring engages, the passage is opened as much as is

possible.

5.3 Attaching an instrument to the motor

All straight and contra-angle handpieces with INTRAmatic connection according

to DIN EN ISO 3964 can be attached.

CAUTION

Make sure that the handpiece is firmly seated on the motor.

The handpiece detaching inadvertently from the motor during treatment is a

hazard to the patient and user.

4

Pull on the instrument before each treatment to check that it is engaged

and locked in place.

CAUTION

Attaching and removing instruments during rotation.

Property damage to the product.

4

Do not attach or remove the instruments during rotation.

4

Only use reliable handpieces.