22

4

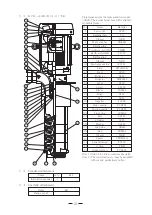

Installation

4.1 Installation

●

●

●

●

●

●

●

●

●

Do not install this pump in places such as machine and chemical factories where

toxic gases including acid, alkaline, organic solvents or paint are present, where

gases containing corrosive elements are generated, or where there are high levels

of dust. Failure to observe this could result in earth leakage or fires.

Do not install this pump in a place that has not been treated for drainage or

waterproofing.

Major disasters could occur if water leaks.

Do not insert foreign objects or fingers etc. into openings (fan cover, discharge port,

suction port, etc.) of the pump. Incorrect doing could result in electric shock,

injuries and damage to equipments.

Do not install in a place as in the obstruction are around the pump to block

ventilation for cooling motor effect. Incorrect doing could result in burns, fires etc.

Do not stand on the pump. Failure to observe this could result in injuries and

damage to equipments.

Do not install a power cable and control cable in the same pipe or duct. Failure to

observe this could result in trouble at this pump or other equipments.

Tighten certainly in the screw part of piping using seal adhesive. Failure to

observe this could result in water leakage.

Do not apply impact on the device or tip it over. There is a risk of damage.

Always clean the area before starting installation or inspection, etc. There is a risk

of injury from slipping or tripping, etc.

Caution

●

●

●

●

●

Before hoisting the pump unit during unloading, loading, and installation, check the

product catalog, the installation drawing, and the instruction manual, etc., to verify

the pump unit weight and the hoist method. Do not attempt to hoist a pump unit

that exceeds the hoist s rated load.

Incorrect hoisting can result in drops and injuries.

Securely install the pump as explained in the instruction manual. Incomplete

installation could result in electric shock, fires or injury from dropping.

Do not use the pump in flammable gas, Incorrect using could result in fire.

Install the product according to applicable laws and regulations (Electrical

Installation Technical Standards, Wiring Regulations). Failure to do so is not only

illegal, it may result in electric shock, fire, or injury from dropping or falling, etc.

In consideration of the product life, select a well-ventilated place, that is free of dust,

corrosive and explosive gas, salt, humidity, steam and dew condensation, and is not

subject to wind, rain or direct sunlight. The motor or control panel insulation could

drop in a poor environment and lead to residual current, electric shock or fires.

Warning

1.The installation should choose the following places.

・A level and strong place without unevenness.

(The vibration acceleration from the outside is about 6.9m/s

2

or less place)

・The place in well ventilated location which using liquid is not hit to the motor,

and which is not exposed direct sunlight.

・The place where the ambient air temperature of a motor must not exceed 40 ℃.

・Select a location where always can easy maintenance. (Secure sufficient space)

・The place which can read the name plate of a product easy. (Please do not

remove the name plate)

2.When hang and carry the pump, use eye-bolts which is beside a motor.

3.Install higher more than 15mm from the bottom of tank. We recommend that set up

as high as possible from the bottom of the tank to prevent clogged of the strainer

with chips and dust.

Summary of Contents for RCD-40A0.75

Page 1: ...1...

Page 2: ...2...

Page 3: ...3 kW Hz min kg V V kW Hz min kg RH Rp dBA Hz Hz Hz Hz...

Page 4: ...4 kW Hz min kg V V kW Hz min kg kW Hz min kg...

Page 5: ...5 3 M M W K No...

Page 6: ...6 3 3 3 M M W K No...

Page 7: ...7...

Page 8: ...8 B A m s2 1 m B...

Page 9: ...9 VC81 6 3 VC82 12 9 VC80 m...

Page 10: ...10 m m V kW mm mm...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13 2...

Page 14: ...14...

Page 15: ...15...