ZHEJIANG KAYO MOTOR CO., LTD.

www.kayomoto.us

63

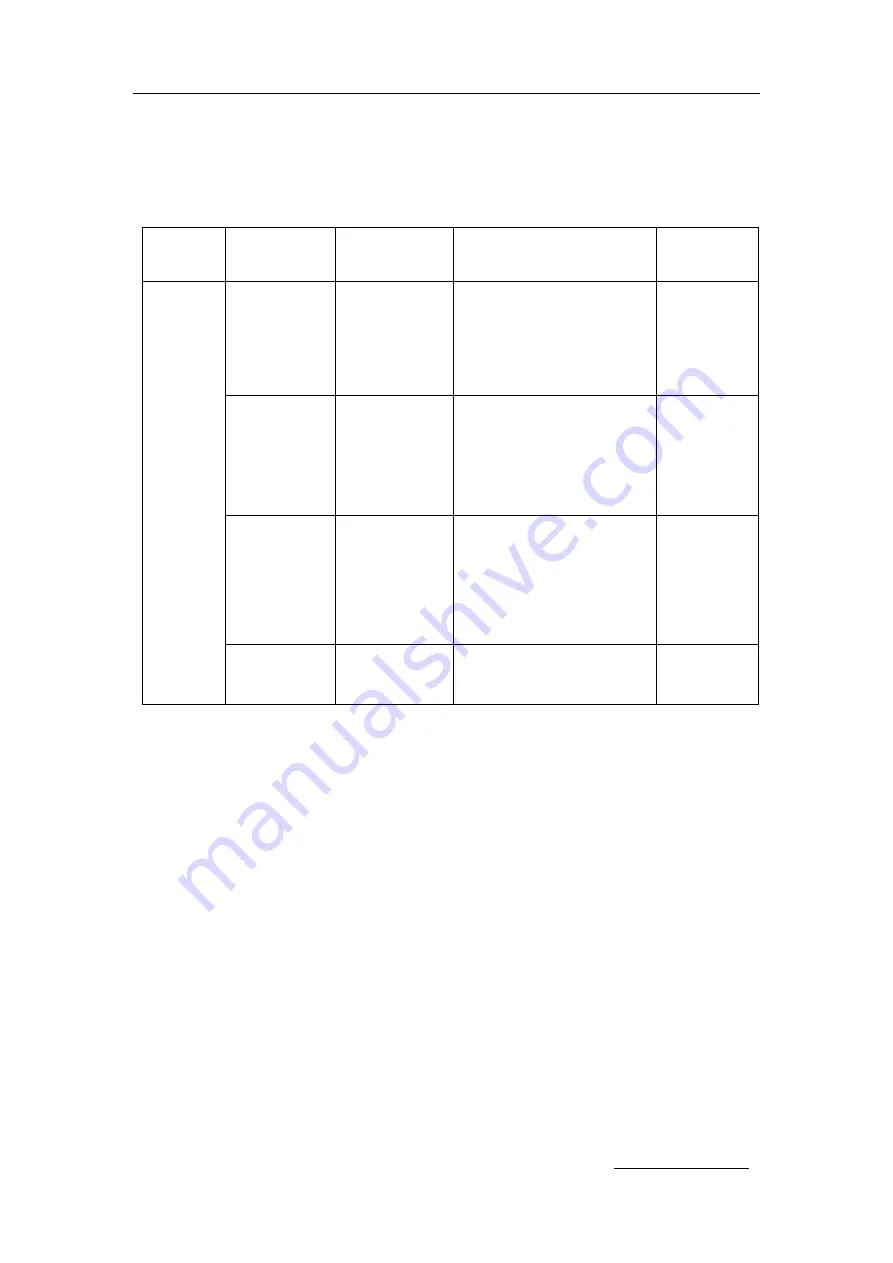

Troubleshooting of the cylinder body, please refer to the following table

Maintenance of Cylinder Body

Description

Damage form

Trouble

Cause

Correction

Cylinder

body

Excessive oil

dirt or sand on

the radiating fins

Poor heat

radiation of the

fins on cylinder

body

The engine overheats

Remove the oil

dirt or sand

Cylinder end

surface badly

distorted

Air leakage

between the

cylinder and

cylinder head

The engine starts hard or fails to

start .Insufficient engine output;

poor idle speed and high fuel

consumption

Grind

the

cylinder

end

surface

or

replace

the

cylinder body

The cylinder is

badly worn

The

fitting

clearance between

the cylinder and

position, position

ring is too wide

The engine starts hard or fails to

start .Insufficient engine output;

Poor engine idle speed. Thick

blue and white fume form the

exhaust muffler pipe.

Repair

with

boring machine

or replace the

cylinder body.

The

cylinder

gasket

is damage

Oil leakage between the cylinder

and crankcase.

Replace the

cylinder gasket

5.4.3 Disassemble, assemble and maintain crankcase

Remove the cover of right crankcase half.

Check whether the oil seal of starting shaft

and seal edge of gearshift lever are worn.

Replace if necessary.