ZHE JIANG KAYO MOTOR CO., LTD

www.RideKayo.com

27

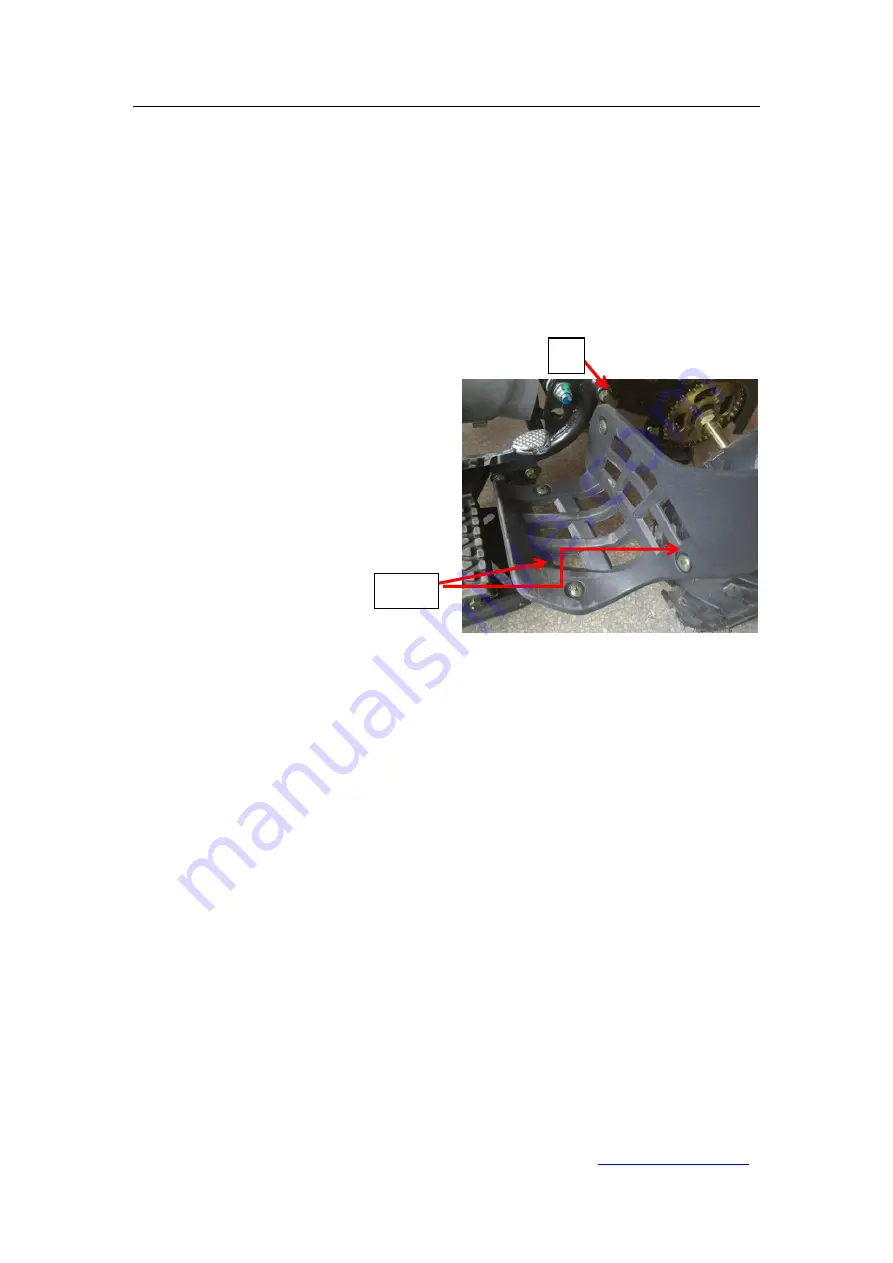

2.3.10 Foot peg guards

Disassembly

1.

Remove mounting bolts 1, 2 and 3.

2. Remove the foot guard.

Installation

Install in reverse order of disassembly.

(

Note: replace mounting bolts, nuts and rubber washers in time, once they worn).

2.3.11 Pedal

Disassembly floorboard/ foot peg

1.

Remove the mounting bolts 1, 2, 3, 4 and 5.

2.

Remove peg bracket and foot peg.

1

2

,

3