EN

16

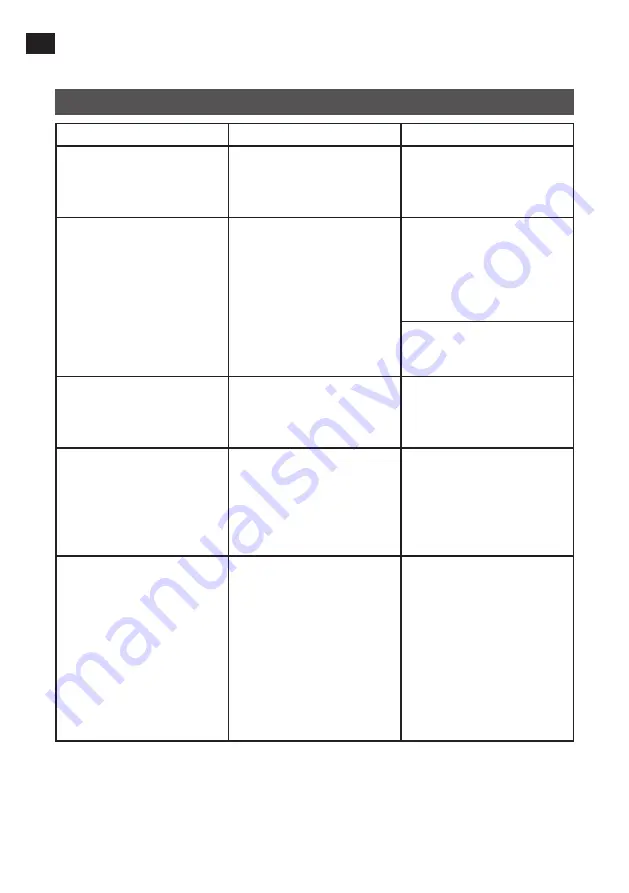

TROUBLESHOOTING

PROBLEM

PROBABLE CAUSE

ACTION

The pressure does not increase

or increases slowly, even

though the product is correctly

connected.

Leakage.

Put the hose in water and

pump to see where air leaks

out.

The pump handle is stiff and

sinks automatically after it is

pulled up.

The non-return valve in the

three stage piston is not

working.

Open the venting valve on the

primary stage tube and drip a

small amount of silicone oil in

the tube. Close the valve and

pump rapidly a few times to

remove the blockage.

Open the three stage piston to

localise the leakage, or replace

the piston seal.

It is easy to pull up the pump

handle, but difficult to press

it down, or it moves up

automatically.

The bottom non-return valve is

defective, blocked or leaking.

Remove the bottom non-return

valve with a spanner and clean

or replace it.

It is more and more difficult to

pump, both up and down.

Inadequate lubrication.

Apply silicone oil.

NOTE: Pump a few strokes

after applying silicone oil to

press out any residual oil.

Excess silicone oil can cause an

explosion.

The pressure gauge is not

reset.

If there is excess oil in the

product the oil and gas will

expand when the pressure

reaches 200 bar. The pressure

will then quickly increase to

400 bar, which exceeds the

maximum permitted pressure

for the pressure gauge and will

damage it. The pressure gauge

can also have been subjected

to knocking.

Replace the pressure gauge.

Summary of Contents for 016592

Page 4: ...2 2 1 3 5 4 6 8 7 9...