05

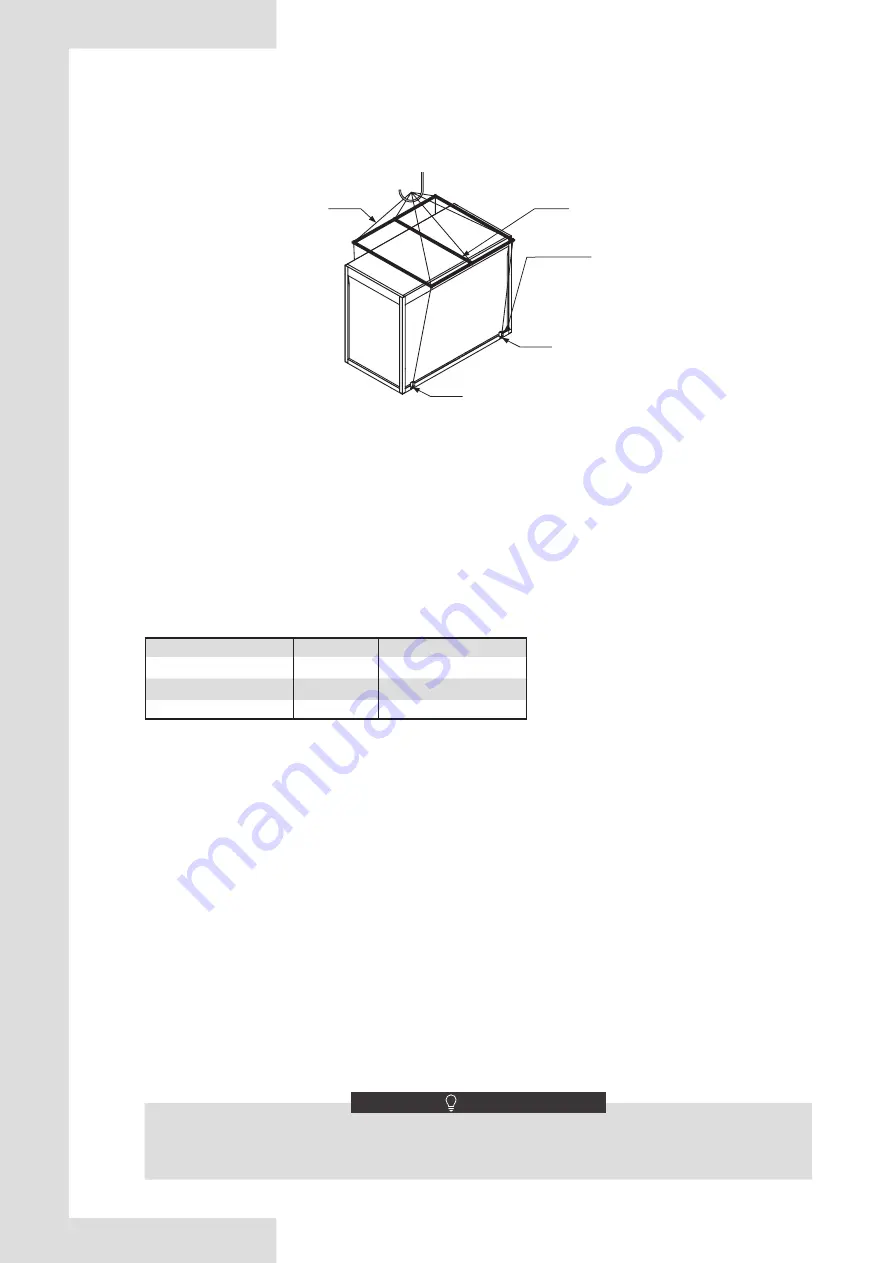

2) Lifting: each lifting rope (belt) should be able to bear 4 times the weight of the unit. Check the lifting hook and ensure that

it is firmly attached to the unit. To avoid damages to the unit, a protective block made of wood , cloth or hard paper should

be placed between the unit and rope when lifting, and its thickness should be 50mm or more. It is strictly forbidden to stand

under the machine when it is hoisted.

the angle of inclinaton

Lifted hook

Lifted cable

Lifted hook

4 protective blocks should be placed.

Unilateral distance should be 50mm or

more.

Fig. 3-1 lifting of the unit

4 IMPORTANT INFORMATION ON REFRIGERANT

This product contains fluorinated greenhouse gases covered by the Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type: R32

GWP value: 675

GWP : global warming potential

The refrigerant quantity is indicated on the unit name plate

• Add the refrigerant

Amount of factory-charged refrigerant and tonnes CO

2

Equivalent is

Table 4-1

Model

Refrigerant(kg) Tonnes CO

2

equivalent

KEM-30 DRS4.1 KH

7.9

5.33

KEM-60 DRS4.1 KH

14.0

9.45

KEM-90 DRS4 KH

16.0

10.80

5 SELECTION OF INSTALLATION SITE

1) Units can be installed on the ground or proper place on a roof, provided that sufficient ventilation can be guaranteed.

2) Do not install the unit in a scenario with requirements on noise and vibration.

3) When installing the unit, take measures to avoid exposure to direct sunlight, and keep the unit away from boiler pipeline

and surroundings which might corrode the condenser coil and copper pipes.

4) If the unit is within the reach of unauthorized personnel, take protective measures for safety considerations, such as

installing a fence. These measures can prevent man-caused or accidental injuries, and can also prevent the electrical parts in

operation from being exposed when the main control box is opened.

5) Install the unit on a foundation at least 200 mm high above the ground, where the floor drain is provided, to ensure that

water does not accumulate.

6) If installing the unit on the ground, put the steel base of the unit on the concrete foundation, which must be as deep as into

the frozen soil layer. Ensure the installation foundation is separated from buildings, as the noises and vibration of the unit

may adversely affect the latter. By means of the installation holes on the unit base, the unit can be fastened on the foundation

reliably.

7) If the unit is installed on a roof, the roof must be strong enough to bear the weight of the unit and the weight of maintenance

personnel. The unit can be placed on the concrete and groove-shaped steel frame, similar to the case when the unit is

installed on the ground. The weight-bearing groove-shaped steel must match the installation holes of the shock absorber and

is wide enough to accommodate the shock absorber.

8) For other special requirements for installation, please consult the building contractor, architectural designer or other

professionals.

NOTE

The selected installation site of the unit should facilitate connection of water pipes and wires, and be free from water

inlet of oil fume, steam or other heat sources. Besides, the noise of the unit and cold and hot air should not influence

the surrounding environment.

Summary of Contents for KEM-90

Page 52: ......